Factors Affecting Determination of Resin whiteness of PVC

Thermal stability is an important performance index of polyvinyl chloride (PVC) resin, which directly affects the application range and service life of PVC products. Therefore, PVC resin manufacturers and processing companies attach great importance to the thermal stability of PVC. At present, the most widely used test method for thermal stability of PVC resin in my country is GB/T15595-2008 "Test Method for Thermal Stability of Polyvinyl Chloride Resin Whiteness Method". This standard is a standard drafted and issued by our country. It is mainly used for the determination of the thermal stability of powdered PVC resin. degree to characterize the thermal stability of PVC.

The whiteness specified in GB/T15595-2008 refers to the radiant energy of the powdery PVC surface to the diffuse reflection of blue light with a spectral characteristic curve peak at 457nm and a half-maximum width of 44nm, which is comparable to that of a complete diffuse reflector under the same conditions. The ratio of the radiant energy is called the blue light whiteness. The main factors affecting the accuracy of whiteness measurement are Whiteness Meter, thermal aging process and testing process, which have a significant impact on the repeatability and reproducibility of whiteness measurement, which will be discussed separately below.

1 The influence of the Whiteness Meter on the measured value of whiteness

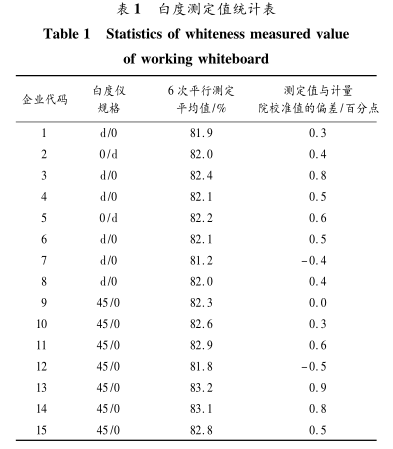

At present, there are many specifications and models of Whiteness Meters used in the PVC industry to test whiteness, which are mainly divided into 45/0, d/0, 0/45, and /d4 specifications according to the brightness and detection methods. In order to verify the influence of the Whiteness Meter on the whiteness test value, the author organized 18 PVC manufacturers to measure the whiteness value of the same working whiteboard.

The whiteness value of the working whiteboard is calibrated by the CHINA Institute of Metrology, and the calibration value is: d/0,81.6%; 45/0,82.3%. Among the 18 companies, there are serious deviations between the data of 3 companies and the calibration value. After verification, it is caused by the light leakage of the Whiteness Meter. The data of these 3 companies are eliminated as outliers. The specific data of other companies are shown in the table 1.

Calculated from Table 1, it can be obtained that the average whiteness of the d/0 specification is 82.0%, the range is 1.2 percentage points, and the coefficient of variation is 1.5%; the average whiteness of the 45/0 specification is 82.7%, and the range is 1.4 percentage points. , the coefficient of variation is 1.7%. The deviation between 45/0 and d/0 is 0.7 percentage points, and the average deviation between the measured value and the calibration value is: d/0, 0.4 percentage points; 45/0, 0.4 percentage points. It can be seen that the reproducibility of the measured values obtained by using the Whiteness Meter of the d/0 and 45/0 specifications is quite good (in the same laboratory, the measured values of 6 parallels are almost completely consistent, and the repeatability is very good. good).

For satisfactory samples, the measured values of the Whiteness Meter of /0, 0", 45/0, 0/454 specifications should be completely consistent in theory. For actual samples, d/0 is similar to 0/d, and 45/0 is similar to 0 /45 is similar, but the difference between the measured values of the four cannot be determined. There is a difference between d/0 and 45/0. This is because d/0 uses a diffuse reflection integrating sphere for color measurement, which cannot completely eliminate specular reflection; And 45/0 uses positioning color measurement, which can better eliminate specular reflection. The color measurement result of 45/0 is the closest to the result of human eye color measurement, but d/0 is the recommended color measurement structure of the International Commission on Illumination (CIE). It is widely used in the world. Therefore, in GB/T15595-2008, the regulation of Whiteness Meter is that both d/0 and 5/0 color measurement structures are acceptable, and d/0 is used as the arbitration, but it should be noted in the test report Indicate the specifications of the Whiteness Meter used.

2 Influence of thermal aging process on the measured value of whiteness

GB/T15595—2008 stipulates that the thermal aging process is carried out in the air aging Test Chamber, and the thermal stability of PVC is assessed by simulating and strengthening the natural environment. Among them, the three factors that have an important impact on the measured value are the thermal aging temperature and the ventilation rate. and box structure.

2.1 The influence of heat aging temperature on the measured value of whiteness

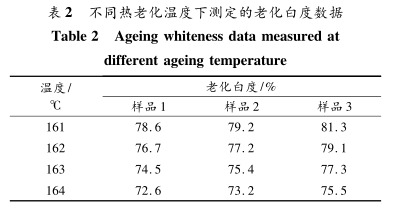

According to the requirements of GB/T15595-2008, four different heat aging temperatures were used under the same conditions to carry out the aging test on the same sample, and the results are shown in Table 2.

It can be seen from Table 2 that for every 1°C increase, the aging whiteness decreases by about 2 percentage points. Therefore, the thermal aging temperature is an important factor affecting the measured value of whiteness, and the test personnel must regularly calibrate the thermal aging box and thermometer to ensure the accuracy of the measured value.

2.2 The influence of ventilation volume on the measured value of whiteness

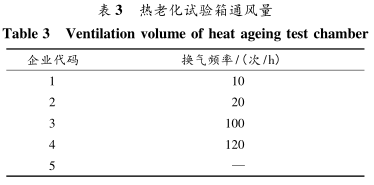

As an important indicator of the heat aging Test Chamber, the ventilation rate directly affects the measured value of whiteness. In the case of constant temperature, a certain ventilation rate (or wind speed) corresponds to a certain oxygen, moisture content and temperature uniformity, and also corresponds to a certain aging environment. The ventilation volume is large, the circulation convection is sufficient, the effect of aging is obvious, and the whiteness value is low, and vice versa. Therefore, when carrying out the whiteness test, the ventilation volume of the aging box should be regulated accordingly. At present, there are many specifications and models of thermal aging Test Chambers used by domestic PVC production and processing enterprises, mainly concentrated in 401A, 401B and 401AB, etc., with different ventilation indicators (as shown in Table 3). The ventilation rate of most domestic aging boxes can only be adjusted simply by manually adjusting the closure degree of the vent hole, and cannot be adjusted quantitatively (the ventilation rate can also be adjusted by adjusting the speed of the blower impeller, but it is generally not used). Foreign thermal aging Test Chambers are relatively professional, and can set the ventilation volume before the test and clearly display it through the instrument during the test, but the price is expensive.

Since there are not enough experimental data with statistical value on the ventilation rate and the corresponding measured value of aging whiteness, the author did not conduct a quantitative discussion on it. JB/T7444—1994 "Air Thermal Aging Test Chamber" has a detailed description of the measurement of ventilation volume, and interested companies can refer to it.

One of the next revisions of GB/T15595-2008 is to make technical regulations on the ventilation rate of the aging Test Chamber in order to improve the reproducibility of the method.

2.3 The influence of the structure of the aging box on the measured value of whiteness

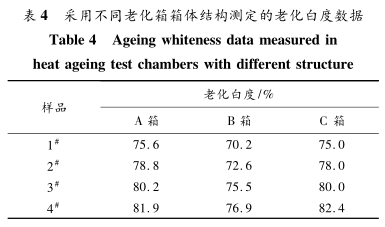

The box structure mentioned here mainly refers to the flow mode and temperature uniformity of the airflow in the aging box. The box structure adopted by each aging box manufacturer is not the same, and the flow form of the airflow in the box is also different. A good structure can make the PVC sample age in an environment with stable airflow, uniform temperature and large effective space. Using three aging chambers A, B, and C with different structures, under the same conditions, the aging test was carried out on the samples. Among them, box A has a hot air circulation channel and a regulating plate, the blower impeller of box B stirs the heated hot air and sends it directly into the working room for circulating flow, and box C shields the blower impeller of box B with thick filter paper, To prevent the hot air flow directly across the surface of the sample. The test results are shown in Table 4.

由表4可见:A、B箱的白度测定值差距非常明显,大约在6百分点。原因如下:A箱内的热气流经过特定的通道在箱体内稳定地循环流动,气流并不直接流经试样表面;B箱内的热气流迅速地流经试样表面,易造成局部短时间过热而导致试样热稳定性下降,白度测定值偏低。A、C两箱体内的空气循环流动方式较为接近,C箱的试验数据很清晰地说明了这一点。JB/T7444—1994中明确规定:加热器件不得构成对试验样品的直接辐射01。因此,避免热气流直接流经试样表面而造成局部老化环境苛刻,对于保证白度测定值的准确是很重要的。

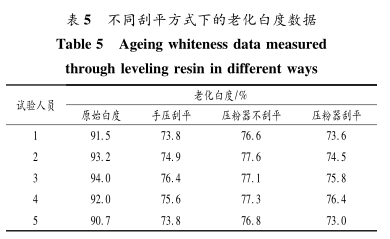

各企业在选用热老化试验箱时,应认真阅读试验箱说明书,选择气流稳定,特别是热空气不能直接流经试样表面的箱体结构,以满足白度检测的需要。3测试过程对白度测定值的影响GB/T15595—2008中规定:试样在压实后用直尺刮平。这是由于试样表面状态对白度测定值影响较大,刮平与不刮平的差异较大,为了统_试样的表面状态,标准对此进行了规定。但在实践应用中发现,由于试验人员刮平的力度和手法不同,导致试料表面的状态事实上不一致,对测试结果产生较大影响。在相同条件下,由不同的试验人员采用手压刮平、压粉器刮平和压粉器不刮平3种方式对同_样品的老化白度进行了测试,原始白度采用手压刮平后测试,结果见表5。

由表5可见:在同一实验室内,不同的试验人员采用相同刮平方式进行制样后所得到的白度测定值的重复性较差,无论是原始白度值还是老化白度值,都清楚地表明了这一点。

采用压粉器制样后不刮平的方式,所测得的老化白度值非常接近,重复性好,这说明采用白度仪附带的压粉器进行制样后无须刮平的方式是降低人为偏差、提高重复性的一个有效途径。

GB/T15595—2008在未来修订时拟将“试样在压实后用直尺刮平”0的表述删除。在目前标准要求“进行刮平”的情况下,各企业应在实验室内部统一刮平的力度和角度,以提高检测的重复性,并在当下不断积累“刮平与不刮平”的试验数据,为标准的修订做好技术上的准备。

4结语

At present, my country's PVC thermal stability test methods include whiteness method, Congo red method (equivalent to ISO182-1:1990), discoloration method (equivalent to ISO305:1990), and hydrogen chloride water absorption method. Each method has its own advantages and disadvantages, and none of them can completely and accurately characterize the advantages and disadvantages of PVC thermal stability, which is one-sided. To accurately evaluate the thermal stability of PVC, the test results of two (or more than two) methods should be combined.

Jinxi Chemical Industry Research Institute Co., Ltd., as the secretariat unit of the all-plastic standard PVC resin branch, is actively applying for the revision project of GB/T15595-2008. After the standard is revised, the reproducibility and repetition of the test results will be better improved Reproducibility (especially reproducibility) is of great significance for improving the technical level of the standard.

- 1Application of whiteness Tester in talc powder

- 2What is the application value of whiteness Tester in cotton

- 3Application of whiteness Tester in Spinning & weaving products

- 4Application of Whiteness Meter in paper

- 5What are whiteness and yellowness?

- 6What is the whiteness index?

- 7How can the paper industry achieve greater whiteness?

- 8What properties should letterpress printing paper be tested for? What are the specific requirements?

- 9Opacity and Transparency Test Methods

-

-

-

-

-

3NH NR4520 whiteness Tester$ 776.00

-

CHENCHI BD-48 whiteness Tester$ 1309.00