Printing ink Colorschemer studio

The empirical color matching method is affected by the subjective factors of the color matcher and other objective conditions. The quality of color matching is difficult to maintain stable, the waste of ink is large, and the utilization rate of remaining ink is low; color matching can only be qualitative but not quantitative, which is not conducive to technology dissemination and communication. The computer color matching system integrates a color measuring instrument, a computer and color matching software. The color data of the basic ink for color matching is stored in the computer in advance, and the mixing ratio of the ink required for color matching can be calculated without cumbersome and expensive trial and error procedures. Get ink recipes.

X-Rite InkFormulation is one of the commonly used ink color matching software in the industry. It can calculate the best ink formulation with the lowest cost according to the printing process, ink, lighting conditions, pigment price, and the number of parts and materials to be used, enabling ink manufacturers Printing and printing companies enjoy greater flexibility in ink formulations and types, improve base material handling capabilities, automatically determine the correct ink thickness, and help eliminate harmful waste ink. At present, ink manufacturers basically use the new version of InkFormulation 6.0; while InkFormulation 5.11 is still favored by printing companies because of its convenience, accuracy and technical maturity in offset ink formulation.

This article takes 1565C on the Pantone Color Chart as the standard color, and introduces the use and operation method of InkFormulation5.11 through the spot color ink preparation process.

Tool preparation: IGT-C1 offset printing suitability Tester, ink injector, electronic balance, Spectrophotometer , standard light source, color matching software, proofing paper strip (choose 128g/m2 double-sided coated paper and cut it into 10cmX5cm specification), ink adjustment knife etc. Ink preparation: transparent white in the Pantone series (as a lightening agent), and green, blue, four-color blue, light blue, blue purple, purple red, ruby red, warm red, orange, yellow, black as the base ink Wait for the ink.

1. Color matching operation method

1. Establish basic ink database

The accuracy of the basic ink database directly affects the accuracy and efficiency of spot color ink color matching. The brand, type and quantity of basic ink and the selection of printing substrates should be determined according to the actual production situation of the enterprise. Generally, more than a dozen basic color inks need to be selected for backup, and two ink databases suitable for coated paper and uncoated paper should be established. . In this example, 12 kinds of inks from Pantone series and 128g/m2 double-sided coated paper are selected to establish a basic ink database suitable for coated paper.

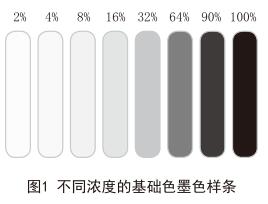

⑴ Mix each basic color ink and transparent white ink into 10g according to 8 different ratios of 2%, 4%, 8%, 16%, 32%, 64%, 90°%, 100°% respectively (precision 0.001g) sample ink.

⑵Use the IGT offset printing suitability Tester to make a good sample ink (see Figure 1), the suitability Tester pressure is 400N, the ink filling volume is 0.12mL, the ink distribution time is 100s, and the ink filling time for the paper sample is 30s. It is required to print 3 color samples for each sample ink, and at the same time print 3 transparent white ink samples and prepare 3 white paper samples for printing.

(3) Preheat the Spectrophotometer for 3 minutes and connect it to the computer color matching system. After the ink on the color sample strip is completely dry (about 1h at room temperature), measure the spectral reflectance data of the white paper sample, the transparent white ink color sample and all the basic ink color samples with different concentrations in sequence. Set the number of measurements to 6 in the color matching system, that is, take two points on each color swatch or white paper sample (select the part with uniform ink color) for measurement, and measure 6 times in total to minimize measurement errors.

Here, the spectral reflectance data is obtained by measuring the color spline, because the spectral reflectance ultimately determines the hue, lightness and saturation of a certain color, and has a high degree of accuracy. The Spectrophotometer converts the spectral reflectance data of each measurement point collected for each measurement into an intuitive Lab or LcM display (Lab and Lch can be automatically converted, and the Lch value is selected in this example), etc. After the 6 measurement results are transmitted to the computer, the system automatically calculates the average value and records it. After that, enter information such as the price of each ink and the total amount of ink to be prepared in the system. After all the work is completed, the basic ink database will be established. The entire process of establishing the basic ink database is very cumbersome and requires careful and careful operation.

2. Sample measurement

Use a Spectrophotometer to measure the color data of the sample (the color requested by the customer, also called the target color, here refers to 1565C) and send it to the color matching system,

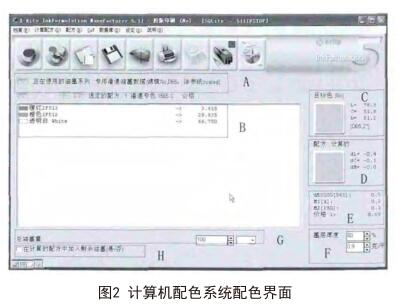

The software will record the reflectance spectrum data of the sample color and convert it into Lch value for display (see Figure 2C).

The color matching system automatically performs a reasonable match from the basic database according to the data of the target color, and quickly generates a spot color formula (see Figure 2B). The system can provide multiple optional formulas and sort the formulas according to various indicators to select a better color scheme. These indicators include color difference, reflectance curve fit, degree of metamerism, color matching cost, etc. The priority of these indicators is determined by the user, and the system will sort the corresponding formulas. In this example, the minimum color difference (45) is selected as the priority index, and the color scheme selected by the system is shown in Figure 2B.

3. Manual color correction

According to the type and proportion of ink used in the formula, according to the pre-set total ink volume (see Figure 2G, this example is 100g), according to their respective proportions, use a high-precision electronic balance to weigh the corresponding amount of warm red and orange respectively. , Transparent white ink, artificially mixed evenly.

4. Color sample

Use the IGT offset printing suitability Tester to make a good sample of the prepared ink. The operation method and parameter standard are the same as the first step (2) of establishing the basic ink database, and make 3 color samples for later use.

5. Color sample measurement

Use the Spectrophotometer to measure the spectral reflectance data of 6 points on the dried color sample strip. The operation method is the same as the step (3) of establishing the basic ink database. The system automatically calculates the average value and records it.

6. Calculation of color difference

According to the pre-set color difference priority, the system automatically calculates the Lch difference between the target color and the ink color obtained according to the formula (hereinafter referred to as the formula color) (see Figure 2D), and calculates the color difference between the two (see Figure 2E).

7. Recipe correction

If the color difference between the formula color and the target color is too large and is not within the required range, you can select "Correction Formula" under the software menu "Formula", and the software will give a new solution. According to the proportion of the corrected formula, repeat the work of manual color matching, color sample printing, color sample measurement, etc. until the color difference value is within the required range, and the formula is qualified.

2. Evaluation of color matching accuracy

1. Color difference evaluation

Color difference is a numerical way to express the visual difference between two colors. The smaller the value, the smaller the color difference, and the larger the value, the greater the color difference. The size of the color difference is related to the light source selected by the Spectrophotometer during measurement. The light source is different , the color difference value is also different. The color difference values of this example (Figure 2E) are at D65, A, and D5. Under the three light source conditions, the calculated color difference values are 0.3, 0.2, and 0.1 respectively. No matter which light source is used, the calculated color difference values are all in the range of 0.0~0.5, indicating that the difference between the target color and the formula color is very large. Small, reaching the high-end product color matching standards required by the industry.

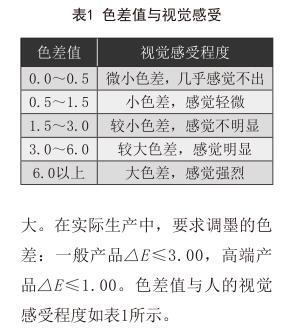

2. Evaluation of reflectance curve fit

The degree of coincidence refers to the degree of overlap of the spectral reflectance curves of the two colors. By comparing and analyzing the spectral reflectance curves of the target color and the formula color, the difference between the two can be seen. like

If the shape of the spectral reflectance curve is roughly the same, and there are many intersections and overlapping segments, it indicates that the degree of metamerism is low. Figure 3 is the spectral reflectance curve of the target color and formula color. The curves at the wavelengths of 420-500nm and 620-700nm basically coincide, while the curves at 500-620nm fluctuate alternately, indicating the reflectivity of the two to light in this wavelength range. There are differences, and there is a phenomenon of metamerism. Because the color difference is very small, the degree of metamerism is very low.

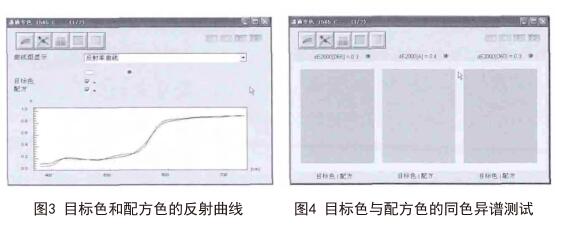

3. Evaluation of metamerism effect

If two color samples that look the same color under one light source have obvious differences when they are illuminated by another light source, this phenomenon is called metamerism. The metamerism effect can be caused by changing the chromaticity observation conditions or changing the illuminant, but the former generally has little effect, mainly considering the metamerism effect caused by the change of the lighting conditions. Each test color block in Figure 4 is composed of target color (left) and formula color (right), and the color difference under the three lighting sources of D65, A, and D50 is less than 0.5, which further illustrates the metamerism of target color and formula color The degree is low, even if the lighting conditions are changed, the human eye cannot perceive the difference between the two.

To sum up, the example of color matching with Pantone Color Chart 1565C as the target color is successful, and the accuracy of color matching has reached the higher standard required by the printing industry.

3. Conclusion

In the past ten years, my country's printing ink industry has successively introduced various color matching systems, but not many have achieved significant benefits. Many practitioners are still accustomed to color matching by manual experience. There are big problems in terms of work efficiency and color matching accuracy, which is still a big obstacle to the standardization and digitization of production in the printing industry. Printing color matching is a complex operation involving light and color theory, ink, paper, technology, etc. The computer color matching system uses color spectrum to perform color matching of tristimulus values, which is suitable for the characteristics of the printing industry, reduces the burden on color matching personnel, and improves the color of products. Quality, speed and accuracy of color matching with added cost-effectiveness. Although the computer color matching system still needs to be improved, such as the color difference calculated by tristimulus value color matching under different light sources, the color matching accuracy has a great relationship with the accuracy of the color spectrum, etc., but with the continuous advancement of computer technology , testing instruments are more sophisticated, various mathematical methods are constantly emerging, and materials are gradually standardized and digitized. Computer ink color matching software will inevitably show incomparable superiority.

- 1Color spectrum computer color scheme software color scheme effect? Xiaotiao takes you to see

- 2Influence of ColorSchemer studio on color scheme results

- 3Discussion on the development of domestic (CN) Colorschemer studio

- 4Color reproduction technology of camouflage spots based on Colibri Colorschemer studio

- 5Colorschemer studio SRICI-PIP and its accuracy evaluation

- 6Practice and analysis of offset spot color Printing ink color scheme

- 7FAQ analysis and countermeasures of emulsion paint color matching

- 8Research on Colorschemer studio of Leather Pigment

- 9ColorSchemer studio Printing ink color scheme