Factors Affecting Gloss of coating powder film

1 Introduction

Powder coatings are different from general solvent-based coatings and water-based coatings. Instead of using solvents as a dispersion medium, powder coatings use air as a dispersion medium. Therefore, pollution is reduced, the environment is improved, and the health of operators is guaranteed. If it is classified according to the state of the powder coating film, it is usually called a glossy coating with a coating gloss greater than 70M, a semi-gloss coating with a gloss of 6M~70%, and a flat coating with a gloss less than 6M. A gloss of 0 or close to 0 is called a matt paint. However, the size of the gloss directly depends on the smoothness of the surface of the object. Therefore, paint extinction is actually the use of various means to destroy the smoothness of the coating surface. The following focuses on several factors that affect the gloss of the powder coating film.

2 test part

2.1 The effect of fillers on the gloss of powder coating film

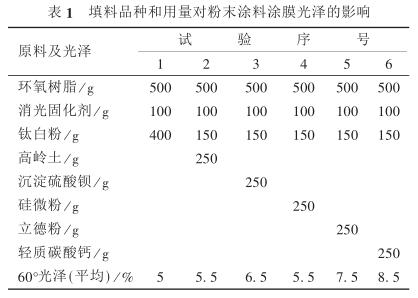

The filler has a matting effect on the coating. The principle is that the filler covers the entire surface of the coating film, destroying the flatness of the coating film and causing a rough surface. However, the coating cannot be matted solely by fillers. Only when the amount of fillers reaches the critical volume concentration, will there be a good matting effect. The use of fillers (talc powder) with low relative density and good suspension force can prevent sedimentation and have a certain matting effect, but this type of filler has certain thixotropic properties, which affects the flow of the coating and makes it difficult to obtain a smooth coating film. Only those fillers (diatomaceous earth, synthetic silica) with low relative density, large porosity and high oil absorption can have a small dosage and good matting effect. In addition to the direct impact of the amount of filler on the gloss of the coating film, the lower the gloss of the filler; on the contrary, the higher the gloss. At the same time, the particle size distribution of the filler also affects the gloss of the coating film. Only fillers with a relatively narrow particle size distribution can be used. Good matting effect. See Table 1 for the effects of filler types and amounts on the gloss of powder coating films.

It can be seen from Table 1 that in epoxy powder coatings, the matting properties of various fillers are ranked as follows: titanium dioxide > kaolin, silicon micropowder > precipitated barium sulfate > lithopone > light calcium carbonate

2.2 The effect of the amount of matting curing agent on the gloss of the coating film

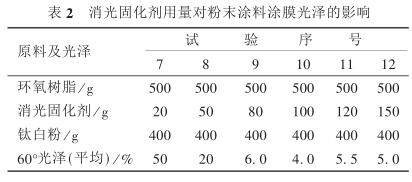

The purpose of using matting curing agent is mainly to adjust the gloss of the coating film, so it is easy to have such a misunderstanding: as long as the amount of matting curing agent is adjusted, the coating film with different gloss can be obtained. Now take the epoxy matting curing agent of Ningbo Nanhai Chemical Co., Ltd., which is the most widely used in CHINA, to do a test to illustrate (see Table 2)

It can be seen from Table 2 that within a certain dosage range, the matting curing agent does have the function of adjusting the gloss of the coating film. Once it exceeds the good dosage range, it does not conform to the rule that the higher the dosage of matting curing agent, the lower the gloss of the coating film. Practice shows that when the amount of matting curing agent is too high, the film is basically formed in the early stage of the reaction, and the possibility of uneven shrinkage in the later stage of the reaction is greatly reduced, thereby reducing the matting activity of the matting curing agent, and instead slightly increasing the gloss of the coating film. high. However, when the amount of matting curing agent is insufficient, it will affect the mechanical properties, physical properties and chemical properties of the coating film. Therefore, it is not appropriate to rely solely on the matting curing agent to adjust the gloss of the coating film.

2.3 Effect of acid value and amount of polyester on coating gloss

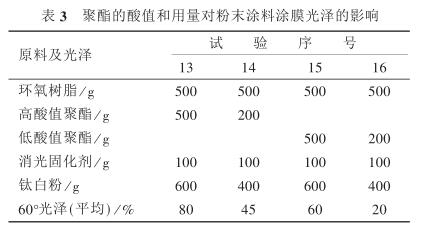

As far as the powder coating itself is concerned, the selection of raw materials also directly affects various properties of the coating film, including affecting the gloss of the coating film. Therefore, before the production of powder coatings, it is necessary to be targeted on what kind of polyester is used to produce coatings with what properties. The test results are listed in Table 3.

It can be seen from Table 3 that, with the same formulation, the gloss of the coating film made of polyester with higher acid value is higher. Conversely, the gloss of the coating film made of polyester with lower acid value is lower. 9 Not only that, the proportion of polyester resin in the formula also directly affects the gloss of the coating film. Practice has proved that in the same formula, the polyester resin with the same acid value is used for testing. The higher the gloss of the coating film obtained, the higher the gloss of the coating film. Conversely, the lower the amount of polyester, the lower the gloss of the coating film.

2.4 Effect of mixed powder method on coating gloss

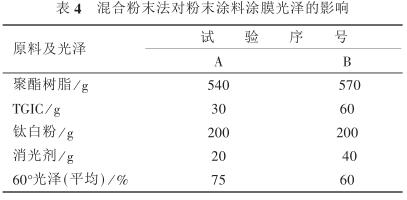

The so-called mixed powder method refers to using the characteristics of similar but different reactivity to prepare at least two kinds of powders and then mix them together to achieve the purpose of matting. The test results are listed in Table 4.

The A and B2 powders prepared according to the formula in Table 4 are mixed according to a certain ratio, and coating films with 12% to 40% of different gloss can be obtained. In this system, the greater the difference in reactivity or the higher the temperature difference that causes crosslinking, the lower the gloss of the formed coating film. However, because it is impossible to mix very uniformly by this method, and the surface tension between powders of different proportions is also difficult to achieve complete consistency, the flatness of the coating film is affected, especially defects such as shrinkage cavities are difficult to eliminate. Therefore, under the current conditions, it is unlikely to be put into production in large quantities.

2.5 Other factors affecting the gloss of powder coating film

The four factors that affect the gloss of the powder coating film are listed above. In addition, there are some factors that also affect the gloss of the coating film, such as ① mixed curing agent, that is, adding several curing agents with different activities during the powder coating manufacturing process Utilizing the difference in chemical reactivity and the difference in curing speed, it causes uneven shrinkage and produces a matting effect; ② matting wax; ③ baking temperature; ④ curing time; ⑤ resin structure.

3 Epilogue

The gloss of the coating film surface is selected according to the user's requirements. In general, noble, beautiful, and luxurious decorations require high gloss; while quiet, comfortable, and elegant environments require low gloss. Generally, machinery used outdoors, car casings, highway guardrails, etc. require high gloss, while cabs, instrument rooms, office equipment, etc. of cars and ships used indoors require low gloss. Especially with the improvement of the material level and the change of people's aesthetic concept, new requirements are put forward for the gloss of the coating film. At present, matting powder coatings have attracted more and more attention, and are more and more favored by users at home and abroad. Relevant data show that matting powder coatings have exceeded 20/% of the global powder coatings production, and have maintained a strong momentum of development. Therefore, researchers in the paint industry should speed up the pace of research and development, deepen research and development efforts, develop more low-gloss and dull powder coating products, and find more convenient, economical and effective ways to extinction.

- 1Determination of thermal plasticity Resin melt flow rate

- 2Molecular weight and distribution characteristics of polyester resin in thermosetting powder coatings

- 3Density Determination Method and Application

- 4Determination method of cone-plate viscometer and its application

- 5Thermal plasticity polyvinyl chloride (PVC) powder coatings in highway engineering: technical requirements and inspection methods

- 6Determination of compatibility of powder coatings: methods, effects and applications

- 7Evaluation of flowability of powder coatings: key factors and significance

- 8Evaluation and Application of Optical Properties of Powder coatings

- 9Importance of powder coatings curing degree and detection method