Influencing factors of waterborne Gravure ink gloss

In order to investigate the influence of the main components and mass fraction of water-based gravure ink on the gloss of the ink, the ink formula was fixed, and ink samples with different dispersibility were prepared; ink samples were prepared by changing the mass fraction of water-based film-forming resin and various additives, The particle size distribution, viscosity and other performance indicators of the samples were tested, and the IGTF1 printability Tester was used to make a sample on the surface of the tipping paper. By measuring the gloss of the sample, the influencing factors of the gloss of the water-based gravure printing ink were studied. Experiments show that: the dispersibility of the water-based gravure ink system and the mass fraction of the water-based film-forming resin have a great influence on the glossiness of the water-based gravure ink; , wax emulsion and other additives can improve the glossiness of water-based gravure ink on the surface of tipping paper.

The safety of food packaging is closely related to people's daily life. Water-based gravure ink has the advantages of no VOC emissions and non-flammability. It is a very promising environmentally friendly printing ink. It is widely used in the green printing and packaging industry and has become a new type of "green" packaging and printing consumables. It has broad market prospects. . The glossiness of the ink refers to the ability of the ink print to reflect light at a certain angle, and its gloss is mainly produced by the conjunctiva after the binder is dried. The gloss of the ink is good, and the color of the printed product is bright; the ink with poor gloss will reduce the promotional effect of the product.

1 Experimental part

1.1 Experimental materials

Pigment: Phthalocyanine Blue M-4000S (Merida Pigment Industry Co., Ltd.); Resin: Waterborne Acrylic Resin 91-5 (Beijing Oriental Acrylic Company), Joncryl617-A, Joncryl142 (BASF); Substrate Wetting Agent: 245, Do75 , Twin4100 (Teco additives); leveling agent: Glide100, Glide410 (Teco additives), levaslipw-461, BASF wax emulsion; cosolvent: absolute ethanol (Beijing Chemical Plant); solvent: deionized water.

1.2 Experimental Instruments

IGT-2S high-speed stirring disperser (Shanghai Sile Instrument Co., Ltd.), D2004W electric mixer (Shanghai Sile Instrument Co., Ltd.), MicrotracS3500 series laser particle size analyzer (Mickey Company of the United States), IGTF1 printing suitability Tester ( Beijing Jinyinlian Image Equipment Co., Ltd.), TC-108DR/A multi-angle gloss meter (Tokyo Denshoku Co., Ltd.).

1.3 Experimental method

Ink preparation: Mix phthalocyanine blue pigment, dispersing resin, ultrapure water and additives, pre-disperse for 30 minutes with an electric mixer, and grind for 120 minutes with a high-speed Grinder.

Particle size test: MicrotracS3500 series laser particle size analyzer is used to measure and analyze the particle size of ink samples. In this paper, the particle size of 95% ink is analyzed.

Base ink thinning: According to the viscosity requirements of gravure ink, add the diluted resin solution and co-solvent to the base ink, and disperse evenly with an electric mixer.

Proofing: use the IGTF1 printability Tester to make a proof on the surface of the tipping paper.

Gloss measurement: measure the gloss of the proofing sheet with the 75° angle of the TC-108DR/A multi-angle gloss meter.

2 Results and Discussion

2.1 The influence of ink dispersion on glossiness

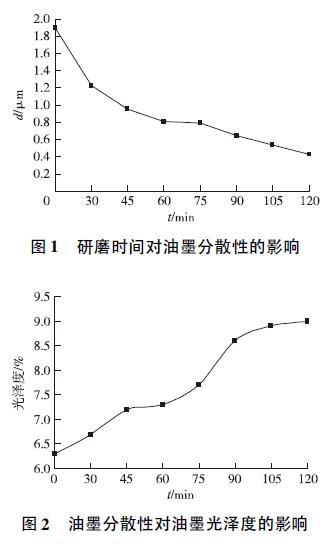

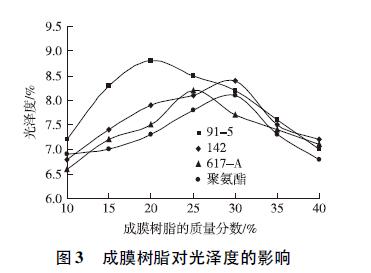

Ink dispersibility refers to the performance of pigment particles dispersed in water or other uniform liquid medium as fine particles suspended in the dispersion medium without precipitation. The dispersion of the ink is good, the smoothness of the formed film layer is high, and the gloss of the proof is also high. In order to study the effect of different dispersibility on the gloss, different grinding times were used to grind and prepare inks, and the particle size d of the prepared ink samples was measured with a laser particle size analyzer to observe the grinding effect. The test results are shown in Figure 1.

2 Results and Discussion

2.1 The influence of ink dispersion on glossiness

Ink dispersibility refers to the performance of pigment particles dispersed in water or other uniform liquid medium as fine particles suspended in the dispersion medium without precipitation. The dispersion of the ink is good, the smoothness of the formed film layer is high, and the gloss of the proof is also high. In order to study the effect of different dispersibility on the gloss, different grinding times were used to grind and prepare inks, and the particle size d of the prepared ink samples was measured with a laser particle size analyzer to observe the grinding effect. The test results are shown in Figure 1.

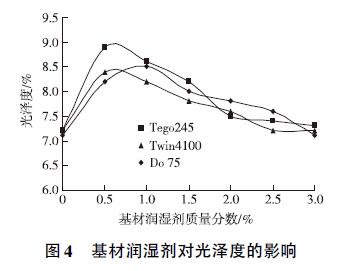

It can be seen from Figure 3 that when the mass fraction of film-forming resin is low, the glossiness of the sample sheet increases with the mass fraction of film-forming resin, but when it exceeds a certain mass fraction, the gloss decreases instead; the type of film-forming resin can also affect For the glossiness of the proofs, the proofs using acrylic resin 91-5 generally achieved a higher gloss in the experiment, while the other three film-forming resins did not perform well in the experiment. When the addition of acrylic resin 91-5 is 20%, the glossiness of the sample sheet reaches the maximum; when the addition amount of Joncr-yl142 is 25%, the sample sheet glossiness value is the largest; when the addition amount of Joncryl617-A and water-based polyurethane is 30%, the sample sheet glossiness reaches the maximum .

When the film-forming resin is added in an appropriate amount, it will have higher surface smoothness and light reflection ability after drying, thus improving the glossiness of the sample sheet; but when the film-forming resin is added in excess, the viscosity of the ink is too small, and the ink sample is on tipping paper. The flow on the surface is unstable, and the gloss of the sample sheet decreases after drying.

2.3 Effect of substrate wetting agent on gloss

Water-based ink uses water as a solvent. The polarity and surface tension of water are higher than those of general organic solvents. Surface tension is an important factor affecting the glossiness of water-based ink. The high surface tension of ink hinders the flow of ink on the surface of tipping paper. Smooth spreading, the surface of the ink film is uneven after the sample sheet is dried, the diffuse reflection increases, and the glossiness of the sample sheet is reduced.

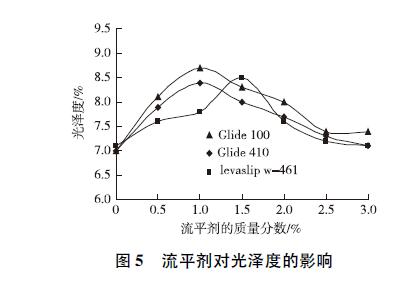

基材润湿剂一般为表面活性剂,由亲水基及亲油基组成,当与固体表面接触时,亲油基附着于固体表面,亲水基向外伸向液体中,使液体在固体表面形成连续相,这就是润湿作用的基本原理。分别添加不同种类和质量分数的基材润湿剂制备油墨样品,实验结果如图4所示。

从图4可以看出,3种基材润湿剂在质量分数较低时,样张光泽度都随着基材润湿剂质量分数的增加明显升高,基材润湿剂质量分数达到一定量时,样张光泽度随着基材润湿剂质量分数的增加而逐渐降低。在Tego245和Twin4100添加量为0.5%左右时,Do75添加量在1%时样张光泽度最高。基材润湿剂的种类也对样张光泽度有影响,Tego245可以使得样张整体光泽度较高。

2.4流平剂对光泽度的影响

流平剂能有效改善油墨在水松纸表面的流动性,改善油墨的流平性,从而使水性凹印油墨有较高的光泽度。固定体系中其他组分,改变流平剂质量分数制备油墨样品,实验结果如图5所示。

从图5可以看出,样张的光泽度随着流平剂质量分数的增加而升高,当流平剂质量分数超过一定值后,样张光泽度随着流平剂质量分数的增加而降低。油墨中流平剂Glide100和Glide410添加量为1%、levaslipw-461质量分数在1.5%左右时各自的样张达到最大光泽度,过量添加反而导致光泽度下降。

添加适量的流平剂能使油墨均匀流动并覆盖在样张表面,降低墨膜上下层对流速度,干燥后样张光泽度相应提高,但过高的流平剂质量分数使墨膜的流平不稳定,干燥后样张光泽度相应下降。

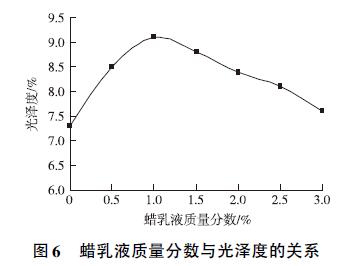

2.5蜡乳液对光泽度的影响

在水性油墨中加入适量的蜡乳液可提高样张光泽度,加入蜡乳液能影响墨膜表面光反射效果,微小光滑的球形蜡颗粒在油墨干燥过程中可均匀分散在样张表面,弥补膜层表面的微小缺陷,提高样张表面的光泽度。固定体系中其他组分,改变蜡乳液的质量分数制备油墨样品,样品光泽度与蜡乳液质量分数之间的关系如图6所示。

由图6可以看出,样张的光泽度随着蜡乳液质量分数的增加先增大后减小。蜡乳液添加量为1%时得到样张光泽度的最大值,之后,随着蜡乳液用量的继续增加,光泽度下降。

In the process of film formation, the wax has a "floating effect", and it is easy to form a "wax film" on the surface. When a small amount of wax emulsion is added, the wax particles on the surface of the coating film are distributed more uniformly, reducing the surface roughness of the coating film, increasing the amount of light reflection, and increasing the glossiness; with the increase of the mass fraction of the wax emulsion, the coating film The wax particles on the surface will "stack" and become uneven, increasing the diffuse reflection and reducing the gloss.

3 Conclusion

The dispersibility of the ink and the type and mass fraction of the film-forming resin have a great influence on the gloss of the ink. The better the dispersibility, the higher the gloss of the ink; when the mass fraction of water-based acrylic resin 91-5 is 20%, the proof reaches the maximum Glossiness; the leveling agent can improve the apparent performance of the ink. When the leveling agent Glide100 is added at 1%, the sample can reach the maximum gloss; the substrate wetting agent 245 with a mass fraction of 0.5% can make the sample get higher The glossiness of the proofs; the addition of wax emulsion can significantly improve the glossiness of the proofs, and when the mass fraction of BASF wax emulsion is 1%, the glossiness of the proofs is the highest.

- 1Principle and Application of Glossiness Tester

- 2Working Principle and Application of Metal Gloss Meter

- 3Basic principle and application analysis of insulating paint gloss Detector

- 4Working principle and application analysis of film Glossmeter

- 5Principle and application analysis of microporous gloss meter

- 6 FZ/T 01097 Analysis of fabric gloss test method

- 7Evaluation and Application of Optical Properties of Powder coatings

- 8Coating coatings - Determination of surface gloss and Gloss meter

- 9The Importance and Method of Gloss Measurement of Paint Film