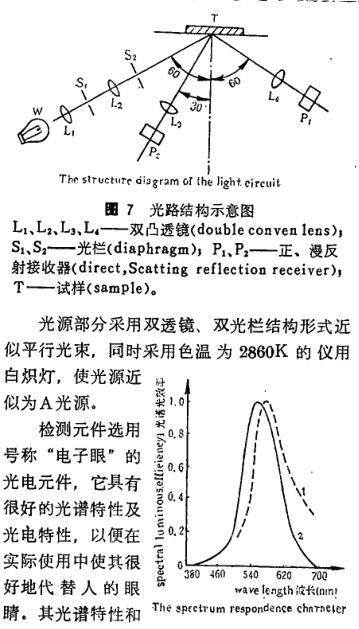

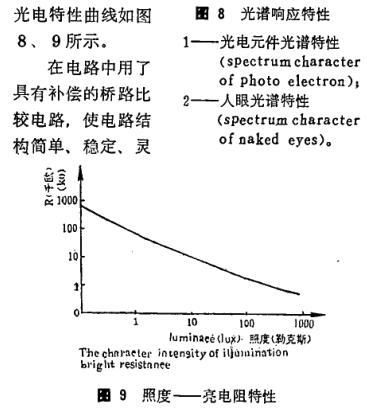

Study on Fabric Gloss and Fabric Gloss meter

Fabric sheen is one of the most important factors in its style, and it has been visually assessed for many years. Evaluation with the eyes will be affected by differences in experience, age, gender, and psychology of observers, resulting in inconsistent evaluation results. In addition, environmental factors (such as weather, direction and intensity of light, etc.) at the time of evaluation also affect the evaluation results. We started research on fabric gloss and fabric gloss meter in 1982. It passed the appraisal in October 1985, and was granted a patent right by the State Patent Office on November 13, 1986.

1. Research on fabric luster characteristics

1. Factors affecting light translation of fabrics

The raw material, thickness, twist and density of the yarn are all factors that affect the luster of the fabric. For fabrics of the same material, the glossiness depends on the external structure of the fabric and the dyeing and finishing process (according to Japanese Industrial Standard Z-8741, under the same conditions, the reflection of optical glass with a refractive index of 1.567 and the difference between QI and reflection ilQ2 of the measured object Ratio called gloss, dimensionless). Therefore, to study fabric gloss, we must first study the relationship between fabric structure and fabric reflective properties.

(1) Effect of fiber refractive index on gloss

Each fiber has a fixed main refractive index, and the size of the refractive index directly determines the reflection characteristics of the fiber. In general, the reflectance of the high refractive index is also white, and the light is also showing an increasing trend. The size of the refraction half varies with the type of fiber material and the arrangement. It is generally believed that the density of z fibers is directly proportional to the refraction stroke. The greater the degree of orientation of the fiber, the average reflection half tends to increase, and the gloss also increases, but the difference in the refraction half of the commonly used fibers is not large (generally between 1.47 and 1.60), so there is no significant difference in gloss. It only affects the transparency and cross-sectional shape of the fiber. If there is a refraction difference above the level of visible light inside the fiber, it will cause the scattered reflection of light inside the fiber, thereby reducing the transparency and gloss. For wool fiber Generally speaking, the state of the scales has a great influence on the luster. The scales of thick wool are thin and close to the hair shaft, the surface is relatively flat, the reflected light is strong, and the luster is also strong. Poor, so the luster of fine wool is soft. If the wool scales are damaged, the luster of wool will become dull.

(2) The effect of yarn and fabric kapok on gloss direction shifting

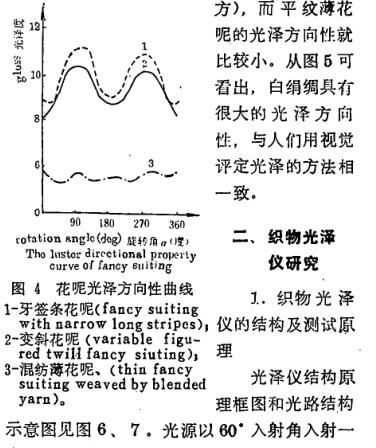

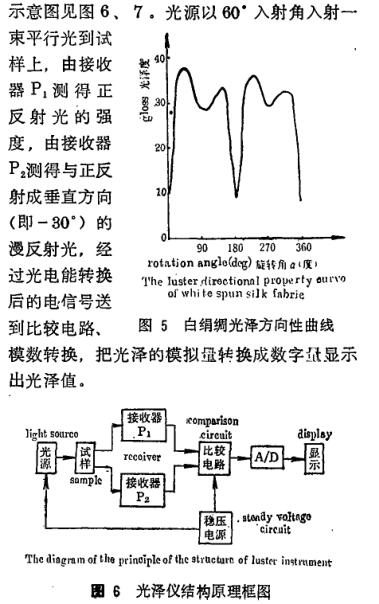

If the yarn surface has a high degree of unevenness, the luster will be mixed and scattered, the yarn will be fluffy, and the co-gloss with a lot of hair and curls will tend to be fuzzy. For fabrics, its type, density, military cover factor, and organizational structure all affect gloss.

(3) Effect of processing technology on gloss

Dyeing and finishing directly affect the luster of the fabric. 3 (Daily calendering, singeing, shearing, voltage, tentering, heat setting, double-roller extrusion, etc., can make the surface of the fabric smooth and increase the luster; while embossing, resin finishing, flocking, etc. The process can darken the luster of the fabric.

(4) Effect of fabric color on gloss

The color of the fabric has a great influence on the light translation test. The diffuse reflection of the object represents the color of the object, while the regular reflection only represents the color of the light source. But the light beam in the direction of regular reflection also contains the component of reflected light. For dark-colored fabrics, especially black fabrics, due to the reduction or elimination of reflection components due to absorption, the gloss value measured from the regular reflection direction is smaller than that of light-colored fabrics. The Triling fabric of the same polyester filament as shown in Figure 1, due to the different shades of the fabric, shows different

- 1Principle and Application of Glossiness Tester

- 2Working Principle and Application of Metal Gloss Meter

- 3Basic principle and application analysis of insulating paint gloss Detector

- 4Working principle and application analysis of film Glossmeter

- 5Principle and application analysis of microporous gloss meter

- 6 FZ/T 01097 Analysis of fabric gloss test method

- 7Evaluation and Application of Optical Properties of Powder coatings

- 8Coating coatings - Determination of surface gloss and Gloss meter

- 9The Importance and Method of Gloss Measurement of Paint Film