Tinned steel plate surface glossiness rolling transfer control

Three types of high-grade cold-rolled steel products—printed tin-plated steel sheets, painted automobile panels, and decorative decorative steel sheets—require for visual aesthetics, which are related to the photophysical effects of the microscopic topography of the steel sheets, specifically manifested in color characteristics, reflective characteristics, and thickness characteristics, image characteristics, uniform characteristics and contour definition, etc. In view of the visual and aesthetic requirements of the surface of tin-plated iron-plated steel sheets, user needs are indexed and quantified to control the target value of glossiness on the surface of tin-plated steel sheets, and a theoretical calculation model of metal surface glossiness is established based on the gloss measurement principle, which has been tested in batch industrial production After the actual measurement data verified the correctness of the gloss theory model, the study revealed the influence mechanism of the steel plate surface micro-topography on the surface gloss , and obtained the influence law of the steel plate surface micro-topography parameters Ra value and Pc value on the surface gloss. Using the gloss calculation model, the gloss control target required by the user is further transformed into the control target of the controllable Ra value and Pc value in the production of tin-plated steel plate, and for a continuous production line of professional DI material tin-plated steel plate in CHINA, a research proposal is made. The process method and technology of tin plate surface gloss control, put into long-term production and stable use, make the gloss quality of the product fully meet the strict requirements of users, and create significant economic and social benefits.

0 Preface

Strip is the backbone product of the steel industry and is widely used . In the process of using strip steel, people pay more and more attention to the visual effect of the strip steel surface and the visual aesthetics of the strip steel surface, in addition to requiring it to meet the basic functions such as bearing capacity, corrosion resistance, and strength. At present, the commonly seen plate and strip steel products that require visual aesthetics mainly include printed tin-plated steel plates, painted automobile panels, and decorative decorative steel plates.

Tinplate, also known as tinplate, can be made into different types of food, beverage cans, packaging boxes for daily necessities, etc. In order to improve the decorative performance of tinplate, tinplate is generally printed, commonly known as printed iron. The iron printing process not only increases the aesthetics of the product, but also a creative and market-friendly packaging will greatly promote product sales. The iron printing process belongs to flat offset printing. Its principle is to use the characteristics of water and ink to repel each other, and with the help of printing pressure, the graphics and text of the printing plate are transferred to the tinplate through the blanket. Due to the smooth metal surface in the iron printing process, the metal surface has no absorption capacity, and tinplate has subsequent processing (bending, pressing, drawing and flanging), so it is necessary to ensure good bonding strength between the ink coating and the tinplate surface , and on this basis, improve the visual aesthetics of the printed iron surface. At present, the visual aesthetic requirements for the graphic surface of iron printing mainly include bright colors, clear graphics, bright luster, and uniform surface. Especially when the surface of printed iron is coated with transparent ink, it is necessary to utilize the inherent metallic aesthetic properties of the tinplate surface, which puts forward higher requirements for visual aesthetics on the surface. At present, the research on the iron printing process of tin-plated sheet mainly involves the study of printing adhesion, as well as the control and online monitoring of the printing quality on the printed iron surface, while there are few studies on the aesthetics of the printed iron surface of tin-plated sheet, such as Li Rui et al. [6] used the fractal method to study the relationship between the surface gloss and lightness of the tinplate and its surface fractal dimension.

Due to its excellent corrosion resistance and decorative properties, painted steel plates are widely used in all aspects of the national economy, among which automotive panels are very representative. The coating process of automobile panels is obviously different from that of iron printing. Automobile coating is generally sprayed, and the surface thickness of the coating can reach about 100 μm, which can completely cover the small-scale rough contours on the surface of the steel plate, and people require the visual The aesthetics is also different from the surface of the printed iron, focusing on the clarity of the image on the surface of the paint film, the apparent smoothness without orange peel defects, and the uniformity of the surface [7]. At present, for the visual aesthetics of automobile panel coating, Kong Xianmei et al. studied the relationship between the surface microscopic surface morphology generated by texturing technology and the sharpness of the paint film. MEZGHANI et al. analyzed the steel plate surface roughness parameters and waviness The relationship between the degree parameter and the sharpness of the steel plate surface.

The structural outer panels, hardware tools, household metal utensils, and high-end metal crafts that are common in daily life all have different requirements for the visual aesthetics of the steel plate surface. We collectively refer to these products as decorative decorative steel plates. During the use of this type of steel plate, because the material itself (stainless steel, copper, etc.) has good corrosion resistance and wear resistance, it is often applied directly without coating, and in order to improve the visual appearance of the surface of this type of steel plate, it is generally carried out. Surface treatment, such as polishing, sandblasting, grinding, etc. However, people's visual aesthetic requirements for this type of decorative steel plate mainly involve surface reflective properties, bright surface or matte surface, surface thickness characteristics such as smoothness or texture, and uniform surface. At present, in view of the visual aesthetics of the surface of such decorative steel plates, Chen Jinshan et al. have focused on analyzing the main influencing factors of the surface gloss of stainless steel and put forward corresponding control methods.

Through the inductive analysis of the visual aesthetic requirements of the above three types of steel plates that are widely used at present, it is found that users focus on the color characteristics, reflective characteristics, thickness characteristics, image characteristics, uniform characteristics, and contour clarity of the steel plate surface. Properties related to photophysical effects of surface microtopography. In view of this, this paper defines the micro-scale visual aesthetics influenced by such surface micro-topography as a kind of micro-surface quality of steel plate, which is distinguished from the macro-scale surface quality of steel plate surface adhesion and damage. Among them, the reflective characteristic refers to the human eye's perception of the light and shade of the surface (bright surface or matte surface, etc.), which involves the ability of the surface microscopic topography to reflect light; the thickness characteristic refers to the surface texture shape (smooth surface or textured surface) that can be recognized by the human eye. ), involving the larger-scale topographical features in the surface micro-topography; the image characteristics refer to the clarity of the human eye's recognition of the image of the reflected object on the surface of the paint film, and involve the scattering of light by the smaller-scale topography in the surface micro-topography; the outline is clear Degree refers to the minimum contour curve recognizable by human eyes, involving the smallest light spot recognizable by human eyes and its reflection on the surface microscopic topography; uniformity refers to the extension of the above-mentioned visual aesthetic requirements for points to surfaces, involving the above-mentioned aesthetic requirements uniformity on the surface.

To sum up, different types of steel plates have different visual aesthetic requirements due to their different application fields. This paper intends to study and select the descriptive indicators of visual aesthetics for the currently widely used tinned steel plate, starting from the physical requirements of users for visual aesthetics (bright colors, clear graphics, bright luster, and uniform surface), and to establish the steel plate from the mechanism. The influence model of the surface micro-topography on the visual aesthetics of the steel plate surface reveals the influence mechanism of the surface micro-topography on the visual aesthetics; at the same time, in view of the urgent need for the control of the visual aesthetics of the steel plate surface in on-site production, the visual aesthetics of the tinplate surface is studied The relationship between property and surface micro-morphology and the corresponding adjustment process and production control technology of visual aesthetics of steel plate surface.

1 Description of the visual aesthetics of the surface of tin-plated steel

Indicators and control targets Brightness, clarity, gloss and chromatic aberration are currently the main indicators commonly used to characterize the photophysical effects of metal surface microscopic topography, which have been widely used and have established standardized definitions and mature measurement methods. Have standardized measuring instruments. In principle, they may be suitable indicators to describe the visual aesthetics of tinplate.

Therefore, according to the user's requirements for the visual aesthetics of the surface of the tin-plated steel sheet, such as reflective characteristics, thickness characteristics, image characteristics, uniform characteristics, and clear outlines, combined with the requirements of a company familiar with the can-making industry, select the above-mentioned possible related indicators—brightness , vividness of image and gloss value, conduct actual measurement research and characterization evaluation for all standard samples provided by users and defect samples with problems such as inaccurate brightness, uneven light and shade, and blurred edges to determine a more suitable visual aesthetics Describe the indicators and their control objectives.

1.1 Determination of description indicators

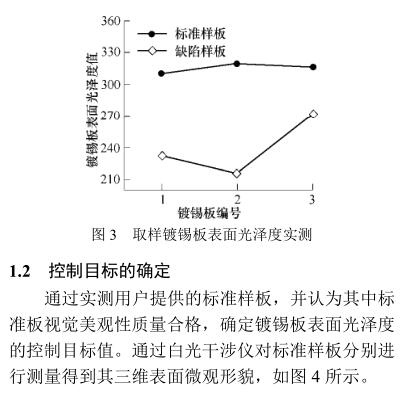

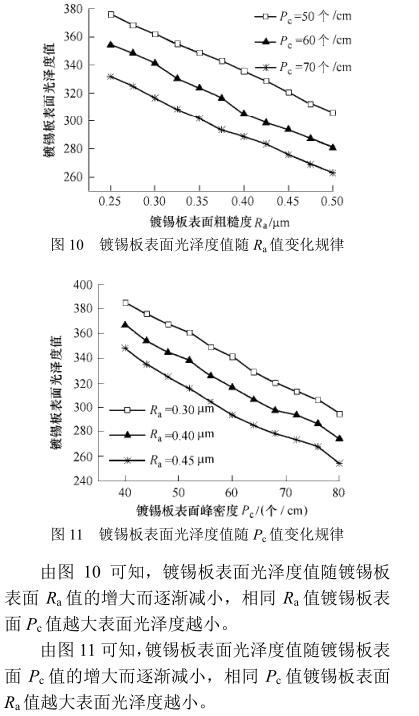

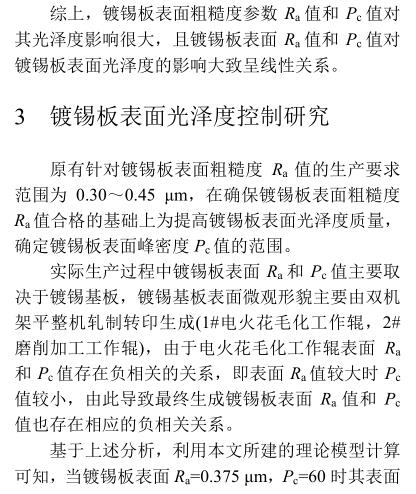

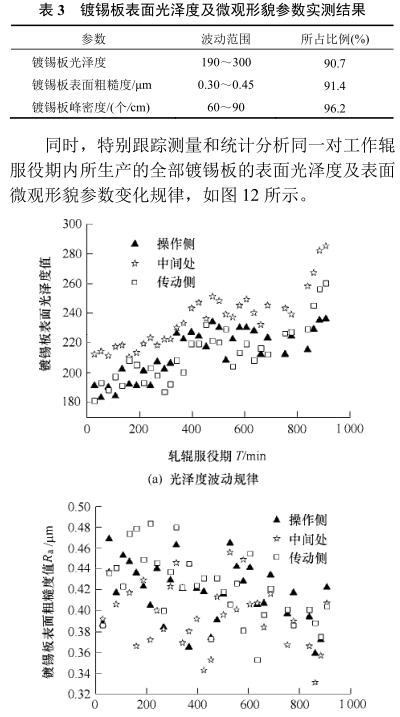

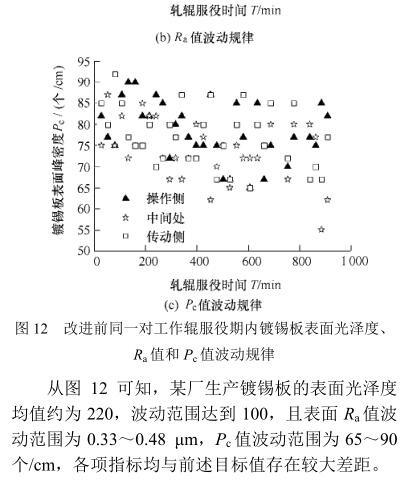

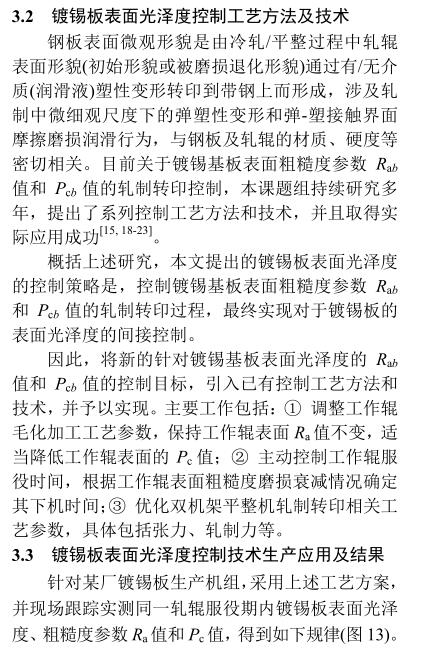

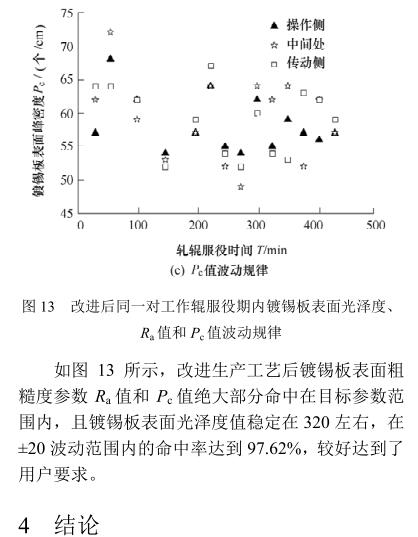

Lightness is one of the three attributes of color (color, lightness, purity), which can measure the degree of lightness and darkness of the surface, and the value of surface lightness is calculated by using the Lab color space method. The degree of distinctness obtains the degree of diffuse reflection of the surface by measuring the scattered light intensity of the reflected light at 0.3°. Gloss refers to the intensity of reflected light on the surface under the action of incident light at a certain illuminance and angle. The measurement results are shown in Figures 1 to 3, respectively.

As shown in Figure 1, the surface brightness value of the standard tinplate is lower than that of the defective tinplate surface, but there is no significant difference between the two. It does not reflect the visual experience of user feedback such as "the surface difference between standard tinplate and defective tinplate is obvious, the surface of standard tinplate is bright and the graphics are clear, while the brightness of defective tinplate is inaccurate, uneven, and the edges are blurred" and other visual feelings . Therefore, it is determined that lightness cannot describe the visual aesthetics of tinplate printed iron reported by users, and is not suitable for marking the visual aesthetic quality defects of such tinplate surface.

It can be seen from Figure 3 that the surface gloss values of the standard tinplate and the defect tinplate are very different, the surface gloss value of the standard tinplate is higher and evenly distributed, and the surface gloss value of the defect tinplate is lower and fluctuates greatly . Relatively speaking, the measured gloss value can more accurately reflect the different visual perceptions of users for standard tinplate and defective tinplate. From this, it can be concluded that the gloss index can reflect the defect problems raised by users, and is more suitable for characterizing the visual aesthetic quality defect of the tinplate surface.

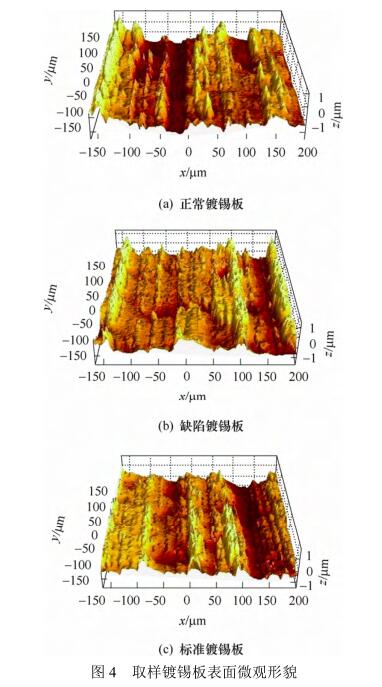

According to Figure 4, the three-dimensional surface microscopic topography and texture of the standard plate, normal plate and defective plate are first compared, and it can be confirmed that the production process of normal, defective, and standard tinplate adopts the same surface control process.

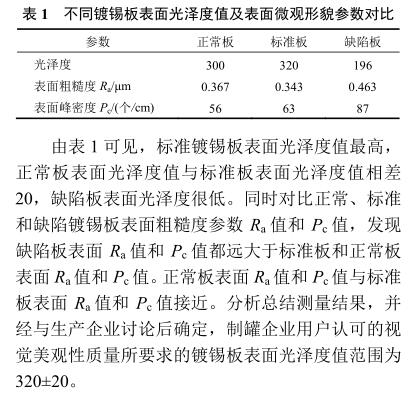

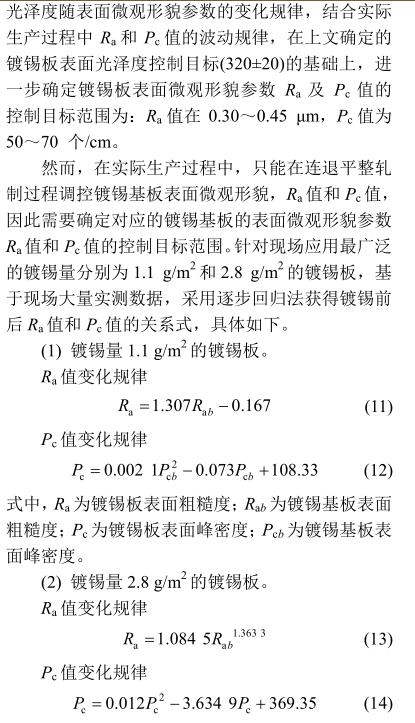

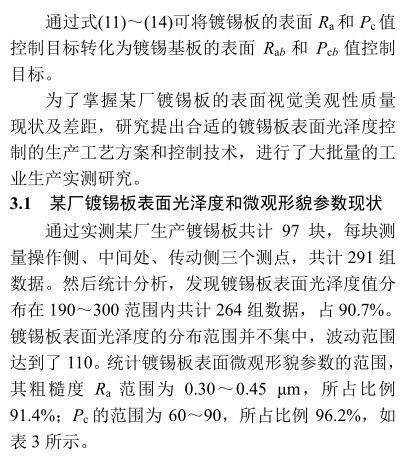

Then, select a reasonable micro-topography control target parameter. From the definition of roughness parameters, the arithmetic mean roughness Ra value refers to the arithmetic mean value of the absolute value of the profile deviation within the sampling length, and the surface peak density Pc value refers to The number of peaks and troughs that exceed the upper and lower limits of the set statistical boundary in the unit evaluation length, so Ra and Pc represent the amplitude characteristics and spatial characteristics of the surface micro-topography, these two parameters can basically reflect the surface At the same time, from the application point of view of the production site, the surface Ra of the strip steel has been widely used as a description index to measure the surface quality of the product, and the Pc value as an auxiliary observation has also been partially used in actual production. , so considering the definition of roughness parameters and the actual situation on site, Ra and Pc are selected as the control targets.

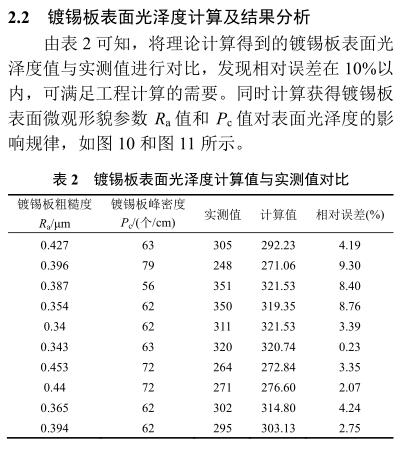

Finally, the surface gloss value, arithmetic mean roughness Ra value and surface peak density Pc value of normal, standard and defective tinplate were measured and compared, as shown in Table 1.

2 Measuring principle and model of surface gloss of tinplate

In the production process of tinplate, the surface gloss cannot be directly controlled, but the microscopic topography of the surface of the tinplate can be controlled during the rolling transfer process of the surface micromorphology of the tinplate, and then the glossiness of the tinplate can be controlled. indirect control. Therefore, it is necessary to study the relationship between the surface micro-morphology of the tinplate and the surface gloss, and establish a calculation model for the surface gloss of the tinplate.

2.1 Establishment of Surface Gloss Calculation Model

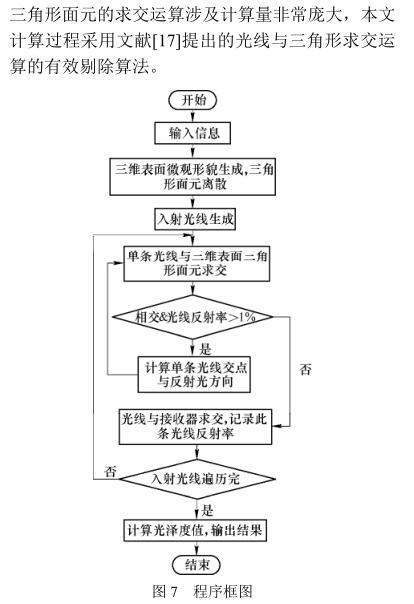

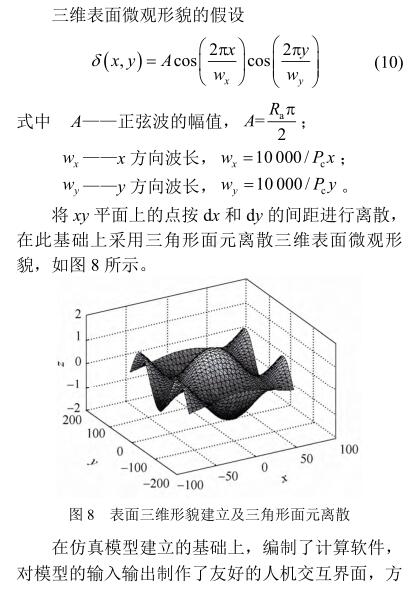

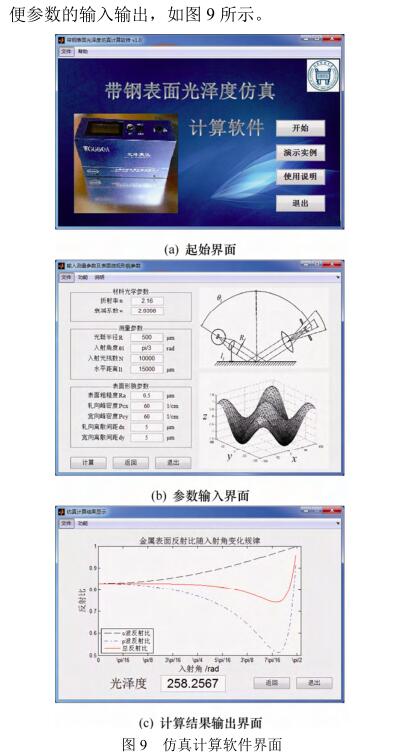

Gloss refers to the ratio or intensity of reflected light on the surface under the action of incident light at a certain illuminance and angle. Factors affecting the surface gloss of the tinplate include the metal composition (internal cause) of the surface of the tinplate and the microscopic geometric unevenness of the surface of the tinplate. degree (external cause). In this paper, the WGG60 gloss meter produced by Shanghai Xinrui Instrument Co., Ltd. is used to measure the 60° gloss value of the tinplate surface on site. The measurement principle is that the incident light spot (visible light) is irradiated on the surface of the object, and the incident light is measured at the specular reflection position. The intensity of the reflected light is obtained to obtain its surface reflectance value and compared with the reflectance of the standard black glass plate, and the surface gloss value of the standard black glass plate is defined as 100, so as to obtain the absolute gloss value of the object surface.

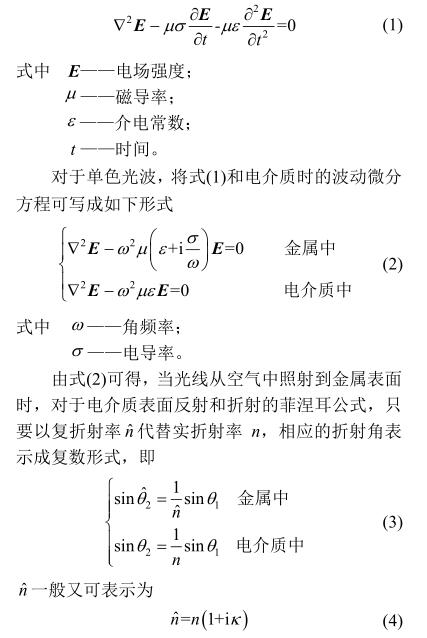

It is known that when a light wave irradiates a metal surface, due to the existence of a large number of unbound free electrons in the metal, under the action of an external field, a conduction current density can be generated in the metal, which is different from when the light wave irradiates the dielectric surface. The wave differential equation obtained from Maxwell's equations is

In the formula

n——The refractive index of the metal, which is equivalent to the refractive index of the dielectric, determines the propagation speed of light waves in the metal;

K——attenuation coefficient, which determines the attenuation characteristics of the amplitude of the light wave when it propagates in the metal.

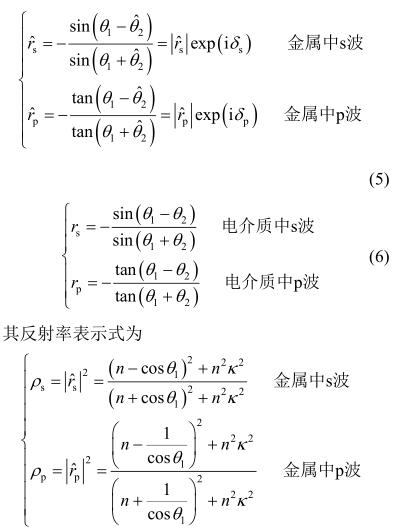

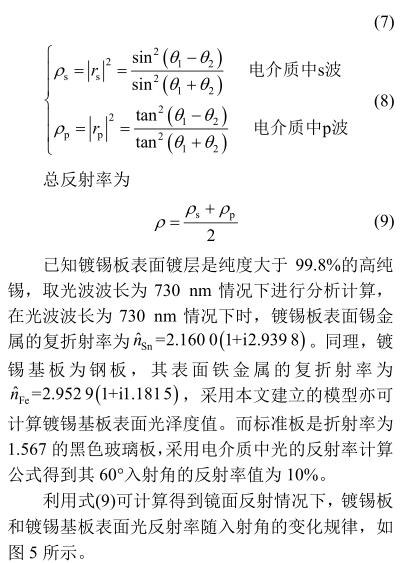

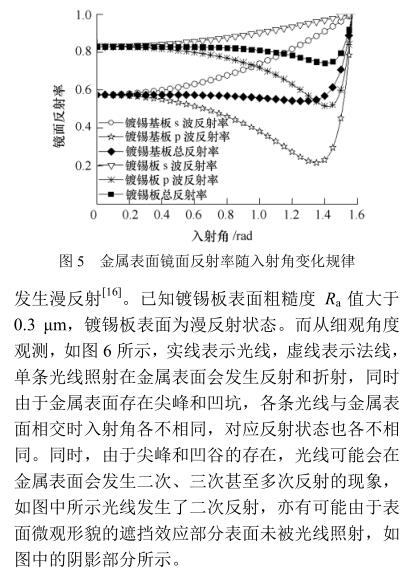

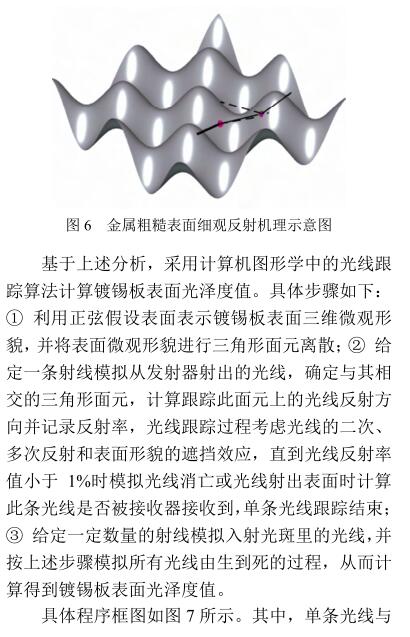

Due to the strong absorption on the metal surface, the phenomenon observed at the interface is almost caused by reflection, and the rewritten Fresnel formula is

- 1Assess rock surface gloss

- 2How to assess the surface gloss of fabric?

- 3Polymer material surface gloss

李健 - 《西南交通大学》

- 4Necessity of surface glossiness measurement

- 5Erosion behavior and mechanism of steel structure surface coating in aeolian sand environment

郝贠洪;邢永明;杨诗婷 - 《摩擦学学报》

- 6Printing ink coating surface performance analysis

- 7Study on Wear Resistant Coating on Resin Surface

- 8Simple method of inspection painting surface treatment effect

- 9Painting Principles for choosing surface treatment methods