Study on Wear Resistant Coating on Resin Surface

Using tetraethyl orthosilicate, KH-560 and KH-570 as precursors, silicone wear-resistant coatings were prepared on epoxy resin substrates by sol-gel method combined with spin coating method. The performance of the coating was tested by pencil hardness test method, scratch test test method of paint film and self-made wear resistance test device, and the surface morphology of the film was observed by scanning electron microscope. The research results show that: the appropriate coupling agent can effectively improve the stability of the coating and the adhesion of the coating; the hardness and wear resistance of the coating increase with the increase of the heat treatment temperature within a certain temperature range; After that, the surface hardness and wear resistance are significantly improved, and the surface quality is significantly improved.

1 Introduction

Epoxy resin has low density, strong impact resistance and good mechanical properties. It is widely used due to its electrical insulation properties and good thermal and chemical stability, but its application is limited to some extent due to its low hardness and poor scratch resistance. Surface preparation of silicone wear-resistant coating can effectively solve these problems. In recent years, the use of sol-gel method (sol-gel) to prepare various functional films has been gradually considered to be very promising. Compared with other traditional coating methods, the sol-gel method has many advantages: the combination of various components can be easily realized, the process temperature is low, the product structure is uniform, the purity is high, the reaction process is easy to control, and the sol is easy to form a film, etc. [sentence. In particular, the process temperature is low, which provides a convenient way to introduce organic components or organic functional groups into the inorganic framework network and create specific functions of the system. One of its applications is in the case of insufficient hardness, poor abrasion resistance, and easy damage. The surface of the object is coated with a hard protective film. By selecting a suitable precursor, a composite film with an inorganic coating on the outside and an organic coating in the middle can be obtained, thus not only meeting the needs of scratch resistance, but also taking into account the tight combination between the film and the substrate. In this paper, tetraethyl orthosilicate and γ-glycidol are selected! Frog oxypropyl trimethoxysilane (KH-560) and γ-methacryloxypropyl trimethoxysilane (KH-570) were used to prepare Luojiao, which was prepared by spin coating on the surface of epoxy resin Inorganic-organic wear-resistant coating.

2 experiments

2.1 Preparation of limb lysis

Mix ethyl orthosilicate, silicon-wan coupling agent, ethanol, and ethyl acetate in a certain proportion, and slowly add an appropriate amount of deionized water, then use dilute hydrochloric acid to adjust the pH value of the banyan solution to about 4, and stir thoroughly for 1-2 hours , and then aged for 5-6h for later use.

2.2 Preparation of thin film The KW-4A Spin Coater is used for coating by the spin coating method. The speed of rotation depends on the size of the component, the concentration of the coating solution and the thickness of the film layer. Under the action of centrifugal force, the banyan liquid forms a uniform colloidal layer on the entire surface of the component. After the surface solvent has evaporated, it is placed in a Forced Air Drying Oven to dry and cure to obtain a wear-resistant coating.

2.3 Performance test

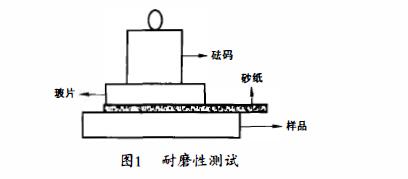

The hardness of the coating film is tested by the pencil hardness test method; the adhesion is tested by the scratch test of the paint film. Abrasion resistance test: Place the resin sheet horizontally, then place No. 240 sandpaper on the coating surface, load a certain quality of silicon code on the sandpaper, pull the sandpaper at a certain speed during the test, so that the sandpaper evenly passes across the coating surface , the wear resistance is represented by the minimum silicon code quality with obvious scratches, as shown in Figure 1. The surface morphology of the films was observed by scanning electron microscopy.

3 Results and Discussion

3.1 Effect of different solvents on the surface properties of the coating

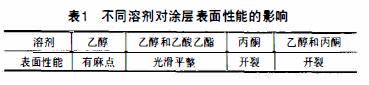

Investigated ethanol, acetone, ethanol and ethyl acetate respectively. The effect of Kunhe solution on the surface properties of the coating when it is used as a banyan agent. The results are shown in Table 1.

It can be seen from Table 1 that when ethanol is used as a solvent alone, pits appear on the surface of the coating. The reason is that due to the strong polarity of ethanol, the prepared sol has poor wettability to the resin substrate, so that pits appear. When acetone and seawater containing acetone are used as solvents, the coating is prone to cracks. There are many reasons for the cracks in the drying process of the coating. Generally speaking, it is related to the stress on the micro-regions in the sol, and there are many reasons for the stress, such as the surface tension during the liquid phase volatilization process, the difference in the thermal expansion coefficient of the interface, etc. , because of the low boiling point and strong volatility of the sol, the solvent and water are removed quickly during the drying process of the sol, which can easily cause uneven tension of the film layer and cause the coating to crack. When the 1-kunheluo solution of ethanol and ethyl acetate is used as a solvent, it not only improves the wetness of the sol to the resin substrate, but also inhibits the rapid volatilization of the solvent and water, so that the coating shrinks evenly without cracking. The obtained coating surface is smooth and flat.

3.2 Effects of different coupling agents on sol stability and coating adhesion

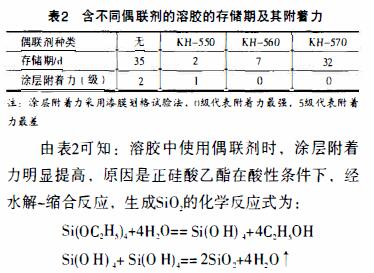

The influence on the stability of the sol and the adhesion of the coating was studied when no coupling agent was used and when KH-550, KH-560, and KH-570 were used as coupling agents. The results are shown in Table 2.

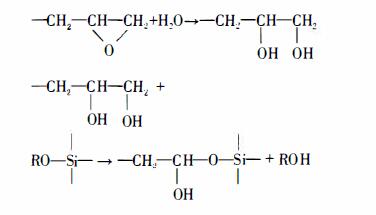

There is a lack of firm bond between the pure elemental oxide film and the epoxy resin. The silicone coupling agent is introduced into the silicone glue, and after hydrolysis, an organosilicon compound film is formed on the surface of the component. The bonding strength depends on the extreme Affinity of the sex chain. Taking KH-560 as an example, its chemical formula is:

从而可以在较低温度下生成既有硅酸乙醋水解生成的Si02,又有硅烧偶联剂水解生成的有机硅网络,这样,既有助于有机硅膜层与树脂基板的结合,又保持了无机硅氧化物的耐磨特性。当然,镀膜液中的硅酸乙醋和硅烧偶联剂需要满足一定的比例,才能更好地使膜层在满足附着力的条件下,提高耐磨性。

从表2还可以看出:KH-550作偶联剂时,榕胶稳定性差,胶凝时间不足2d(通常把由陈化开始至容器倾斜液体不流动的间隔时间称为胶凝时间)。其原因是KH-550是氨基硅皖偶联剂,水解后放出氨气,氨是碱性催化剂,使溶胶过快缩聚胶凝OKH-560作偶联剂时胶凝时间较KH-570作偶联剂时短,其原因有待进一步研究。

3.3溶胶浓度对涂料和涂层性能的影晌

溶胶浓度的大小将直接影响涂层的厚度,进而影响涂层的耐擦伤性能。通常情况下,厚度越厚涂层耐磨性越好。表3是溶胶浓度对涂料性能的影响。由表可见,随着溶胶浓度的增加,涂层的硬度提高,但是存储时间缩短3随着溶胶浓度的增加,涂层的厚度增加,因此硬度得到了提高。但是,并不是溶胶浓度越高越好。

因为痞胶浓度过高时,由于固化成膜时所得涂层厚度过大,涂层内聚力增加,导致涂层开裂且黠结力差.硬度反而降低闷。一般情况下,溶胶浓度不应超过20%,但也不能太低,浓度太低,所得薄膜太薄,薄膜呈现五彩色。较好的溶胶浓度应该控制在12%~14%之间。

存储时间缩短是由于溶胶浓度较高,Si-OH之间以及Si-OH与Si-OR之间发生缩合反应的几率变大造成的。

3.4热处理温度对涂层性能的影晌

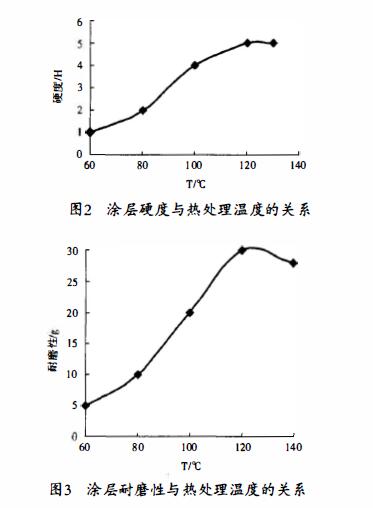

图2和图3分别为热处理温度对涂层硬度和涂层耐磨性的影响。

It can be seen from Figure 2 and Figure 3 that: before 120 °C, with the increase of heat treatment temperature, the hardness and wear resistance of the film are significantly improved; the hardness of the film reaches the maximum value when the heat treatment temperature reaches 120 °C, which is SH; wear resistance reaches its maximum value when the temperature reaches 120°C. The land boundary load is 30g. However, an excessively high curing temperature does not help to increase the hardness of the coating, but instead reduces the scratch resistance of the coating. The main reason is that due to the high curing temperature, the cohesion in the coating increases, resulting in a decrease in the sweetening force between the coating and the substrate. As a result, the coating is easily peeled off from the surface of the substrate when subjected to friction, and the scratch resistance is reduced.

No matter for what kind of plastic, its heat treatment temperature can not exceed its glass transition temperature, generally lower than the glass transition temperature more than 10 ℃, otherwise the product deformation will seriously affect its surface shape quality. The glass transition temperature of the epoxy resin used in this test is 140°C, so the heat treatment temperature of this test is 120°C.

3.5 Effect of coating on surface quality of resin matrix

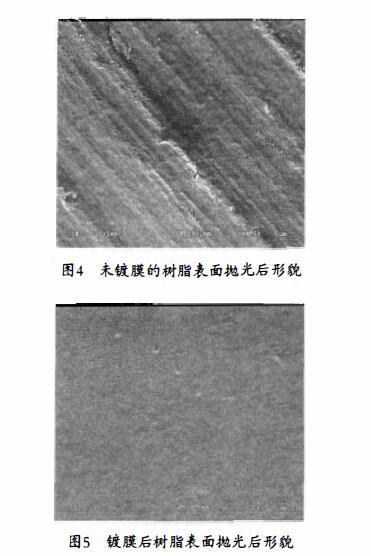

Figure 4 and Figure 5 are SEM pictures of the resin surface. From the comparison of Figure 4 and Figure 5, it can be seen that due to the low hardness of the resin and poor scratch resistance, it is easy to cause mechanical scratches on its surface polishing, which cannot make the surface smooth and smooth. After grinding the coating, due to the high hardness and good wear resistance of the coating, it can be slightly polished to obtain a smooth and flat surface, which significantly improves the surface quality.

4 Conclusion

Using the sol-gel method combined with the spin coating method to prepare an organic transition layer on the surface of the epoxy resin, the outer layer is an inorganic layer, and the middle is an organic transition layer.

- 1Erosion behavior and mechanism of steel structure surface coating in aeolian sand environment

郝贠洪;邢永明;杨诗婷 - 《摩擦学学报》

- 2Effect of titanium dioxide sol content on wear-resistant coating performance

冯海兵;欧迎春;谭欢 - 《涂料工业》

- 3Printing ink coating surface performance analysis

- 4Tinned steel plate surface glossiness rolling transfer control

- 5Simple method of inspection painting surface treatment effect

- 6Painting Principles for choosing surface treatment methods

- 7Main content of surface treatment before lame plating

- 8The basis for the selection of painting surface pretreatment methods

- 9Content and significance of painting surface preparation