Analysis of Influencing Factors and Control Methods of Coating Color Reproduction

1 Introduction

Paint is a kind of material with decoration, protection and special functions. With its wide application and development, the products are diversified and the effects are diversified are painted colorfully to show their individuality and fashion. With the increasing maturity and development of the domestic paint industry, customer requirements have also changed. Orders of the same color have begun to increase, and the requirements for color and color difference ability and reproduction level of enterprises. Focusing on the more concerned and difficult color difference problem in the industry, this paper summarizes a color and discusses it, hoping to be helpful to paint production.

2 The concept and status quo of color control

2.1 The concept of color reproduction and color difference

Color reproduction in paint refers to: the customer provides a certain color sample or a certain color in the designated Color Chart, and the manufacturer makes paint with the same color, or the same standard color, and supplies them in multiple batches. difference. In fact, the colors of any two or two batches of paints cannot be exactly the same, and there are more or less differences between them. In order to further improve and unify the color evaluation method, the International Association of Illumination (CIE) proposed a standard color difference in 1976 The formula has now become an international standard . Color difference, that is, the numerical method to express the difference in color perception between two colors, the formula is as follows:

ΔE=[(Δa)2+(Δb)2+(ΔL)2]1/2

In the formula, L represents the psychological lightness, a and b represent the psychological chromaticity, and Δ represents the change value.

This has great reform significance in color reproduction, and it has also led to the rapid development of color measuring instruments. Some domestic and foreign manufacturers such as Konica, Minolta, X-Rite, BYK, and Jiaxing have launched excellent products one after another, which makes Color reproduction is more targeted and controllable.

2.2 Status and Significance of Color Control

For color control, many domestic paint manufacturers still rely on colorists or color technicians who are engaged in color toning. Although the control level has improved with the rapid promotion and popularization of some professional color measurement equipment, due to human or instrument use The misunderstanding of color control is still a very difficult problem for paint manufacturers. Although the relevant departments have done a lot of work and regulations, it is still impossible to form a set of effective methods. How to better promote the development of paint and increase the market proportion of paint applications , obviously it is imminent to formulate a set of standardized color control methods.

3 Analysis of Factors Affecting Color Judgment

3.1 Tool for selecting color——Color Chart

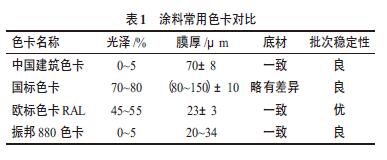

The comparison of commonly used Color Charts for paints is shown in Table 1.

The more commonly used Color Charts on the market are industrial Color Charts and architectural Color Charts, and some Color Charts are used by enterprises themselves. Due to the incompleteness of customers' own tools and usage habits, printing Color Charts and industrial Color Charts are mixed.

There is also a phenomenon of color difference in individual colors between different batches of the same series of standard Color Charts, and between different Color Charts in the same batch, which makes the two parties may already have differences in the color confirmation and measurement standards, and this There is a great deal of uncertainty about these differences.

3.2 The subject of color judgment

People are still the subject of evaluating and judging color difference. Under normal circumstances, although the naked eye observation is very sharp and the resolution is high, it has certain limitations: it is often powerless to do anything about the nuances of different saturations, and it is difficult to make accurate comments on the test results; what's more There are differences in the ability to distinguish between ordinary people and professionals, and between people, and the experience of judging colors needs to be accumulated for a long time; it is also reported that as people grow older (after 40 years old), the ability to distinguish colors appears. This also makes the judge an uncertain factor.

3.3 Factors of the coating film itself

(1) Diversification of coating varieties

Due to the influence of high-end performance, price, environmental protection, special purpose, imitation of other materials and other factors, the variety of coatings has become more and more complex. Coatings are also rapidly maturing. Due to the large differences in their respective film-forming effects and apparent states, it has caused great obstacles to color evaluation, and the evaluation difficult.

(2) The common disadvantages of the paint itself --- floating color, blooming phenomenon

In fact, the phenomenon of floating color and blooming should belong to product quality problems. The purpose proposed here is that floating color and blooming are often complained in the form of color difference, which will make the paint present an uncertain color and effect. Therefore, the stability of the color And the premise of controllability is that the pigment is fully wetted and evenly dispersed in the paint .

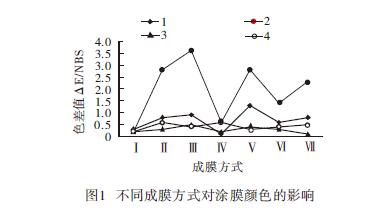

(3) The influence of different film-forming methods on the color of the coating film

An example is as follows: select two-component solvent-based steel structure fluorocarbon paint with good hiding power and poor hiding power, and use a color difference meter (MINOLTA CM-508d) to measure the color difference, taking the European standard Color Chart (K7) as the standard sample, The test results are shown in Figure 1.

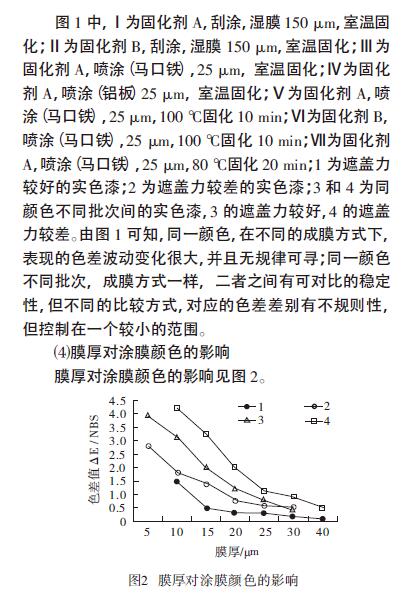

In Figure 2, the samples are all cured by curing agent A, sprayed ( tinplate ), and cured at 100 °C for 10 min. 1 is solid color paint with good hiding power; 2 is solid color paint with poor hiding power; 3 is metallic paint with good hiding power; 4 is metallic paint with poor hiding power. It can be seen from Figure 2 that the solid color paint with good hiding power tends to be stable when the dry film thickness is not less than 15 μm; the solid color paint with poor hiding power tends to be stable ; For better metallic paints, the color tends to be stable when the dry film thickness is not less than 15 μm; for metallic paints with poor hiding power, the color tends to be stable when the dry film thickness is not less than 20 μm. The reason for the large color change when the dry film thickness is less than 15 μm is that the color of the substrate affects the color , and there is a hue shift.

3.4 Misunderstandings in the application of Colorimeters and McDonald's theory

一直以来,色差仪的使用给涂料制造带来诸多的便捷,但同时对色差的评价结果又出现很多争议,典型的例子:色差值很小(ΔE < 0.5),但看起来不相近;色差值明显(ΔE=1.5),看起来却相近。这里除了两者比较的前提不一致外,那就是人对不同颜色的色彩差别量的不同所引起的一种现象———“麦克亚当”现象,各种颜色区域的宽容量不一样,蓝色区最小,绿色区最大,这也是人眼对不同颜色敏感差异的主要原因,敏锐高低的顺序依次为:蓝、紫、青、橙、黄、绿。所以仪器能够正确反映颜色之间的差别, 但因为使用的笼统性和特殊性,对它产生一定的误解。

4 解决颜色复制问题的途径

4.1 涂膜颜色控制方法

如上所述是影响颜色变化的主要因素,颜色评价是一个过程,过程中的每个环节之间又相互制约,所以颜色可控的前提是过程简单化,这也就是要求环节稳定规范化。经过几年的研究与积累,归纳出一种适合实际生产的可控性强的方法,此方法分为两部分:①比色样板制作;②测量。简介如下。

(1)比色样板制作要求规范

成膜规范化,即在成膜方式、成膜底材、膜厚、烘干条件、固化剂品种等条件保持固定的前提下制作比色样板;溶剂型色漆和金属漆多采用喷涂法,水性色漆多采用刮膜法,其中:喷涂实色漆干膜以膜厚(30±3)μm为佳 ,金属漆干膜膜厚以(20±3)μm 为佳;以通用或外来色卡为标准的一般订单,按如上方式制作比色板即可;若是以样板为标准的一般订单,要模仿其膜厚和复合涂层,达到相对一致,在可对比的前提下去评价;若同颜色不同批次间的订单,一定要严格按照上批相同的方式制板(工程建筑用按下一批补上一批方式,工业用需要与第一批保持一致)。

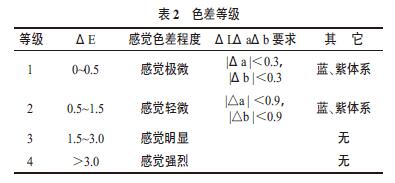

(2)测量与等级划分

使用色差仪来测量颜色色差,在其选择上,选择精度高的、稳定的仪器(可测量金属漆的更好),采用 D65光源测色;对测试结果按表 2 色差等级划分。

一般订单不大于 2 级可通过,批次订单不大于 1级可通过;特别提出的是金属漆如参照如上等级,按一定的比例可适当拓宽色差值范围。

4.2 控制方法剖析与讨论

(1)略显烦琐的比色样板的制作过程,其目的是排除大部分人为或非人为的因素,使准备对比的样板之间有可对比性,能够客观地反映出它们之间的差别。

(2)要求仪器采用 D65 光源测量的目的是用较接近自然光的光源测量,能够与人眼目测效果保持相对一致,仪器显著的优势是恒定的测试光源、角度,稳定的测量方式,是人无法比拟的。

(3)表 2 中 1、2 等级提出的“ΔLΔaΔb”范围的目的是为了通过对色相的窄幅限制提高对颜色的认可程度;与之对应的“蓝、紫色体系”,是为了因颜色敏锐差异的问题提出重点提示与严格要求,其它色系可适当放宽

(4)批次订单不大于 1 级可通过,这也是色彩复制的中心点:批次要稳定,也是企业应该要求严格的环节,因为市场大部分的投诉来源于此,也是衡量企业复制水平的关键所在。

(5)金属漆(包括铝粉漆)由于其复杂的表面状态和不规则的返光效果,采用如上方法时,可能因不同厂家的仪器的限制和水平,测试误差相对较大,但仍有很高

的参考性和调色指导性。

5对生产调色的建议

(1)生产调色使用的通用色卡,相同色卡之间需要进行颜色校正,并且需定期统一更新;

(2)生产调色时,颜色应以包装前的涂料评价为最终结果,需留样;

(3)调色最难的地方是如何把色相调正(尤其是灰色系),而仪器测量 ΔaΔb 能够很好地控制色相的方向性,并能在调色过程中使用正确的色浆或颜料;

(4) The important principle in toning is that the color is similar, that is, the color paste or pigment that is the same or similar to the color of the standard plate is used. The advantage is to control the cost of toning and keep the color stable.

6 Epilogue

The control method of the paint color reproduction is obtained after several years of practice, which is in line with the development status of the enterprise and is easy to implement. Color reproduction itself is not complicated. What is complicated is that in the paint manufacturing process, there are many uncertain factors and lack of understanding, which complicates the result. The height cannot be climbed . Therefore, after the color reproduction fundamentally solves the problem, there are many construction techniques to make up for it, and it is very easy to maintain the stability of the color.

- 1Pigment tinctorial strength quantitative determination

- 2How is the yellowing resistance of films determined?

- 3Paint Film Appearance and Optical Properties inspection method--Paint Film Color Determination Method

- 4Analysis and measures of film defects caused by Color defects

- 5Color of film Appearance performance test

- 6Main inspection items of coating powder film

- 7[Architectural coatings Formula Guide] Design principle introduction and Coatings Formula Guide

- 8Film Color measurement method and steps

- 9[Film Properties and Measurements] - Color determination of film