Principle and Comparison of Several Moisture Determination Methods

There are many methods of moisture determination, and we should choose according to the nature of the food when we choose. The commonly used moisture determination methods are as follows:

1. Heat drying method:

①Atmospheric pressure drying method (this method is widely used);

② Vacuum drying method (used when some samples are heated and decomposed);

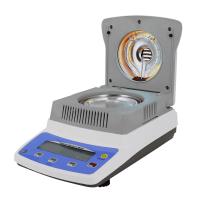

③ infrared drying method (this method is widely used);

④ vacuum drying method (desiccant method);

2. Distillation

3. Karl Fischer method

4. Determination of water activity AW

Next, we describe the methods of measuring moisture respectively.

1. Atmospheric pressure drying method

1. Features and principles

⑴Features: This method is widely used, the operation and equipment are simple, and it has a very high accuracy.

(2) Principle: Moisture in food generally refers to the substance lost by heating at about 100°C under atmospheric pressure. But what is actually lost at this temperature is the total amount of volatile substances, not all water.

2. The drying method needs to meet the following conditions (for food):

(1) Moisture is a volatile component

This means that only water evaporates when heated. For example, samples containing alcohol, essential oils, and aromatic fats cannot be dried, as these have volatile components.

⑵Moisture must be completely evaporated

For the bound water in the jelly formed by some sugars and pectin and gelatin. They are very firmly combined and should not be removed. Sometimes the bound water in the sample cannot be removed after the sample is baked. Therefore, the moisture content of drying at atmospheric pressure is not the total moisture content in the food.

(3) The chemical changes of other ingredients in the food due to heating can be ignored.

Example: Reducing sugar + amino compound △ → color change (Maillard reaction) + H2O ↑

There is also H2C4H4O6 (tartaric acid) + 2NaHCO3 → NaC4H4O6 (sodium tartrate) + 2H2O + 2CO2

Fermented sugar (NaHCO3+KHC4H4O6)△→H2O+CO2+NaKC4H4O6

Not suitable for high-sugar and high-fat foods

As long as it meets the above three points, the oven drying method can be used. The oven drying method is generally carried out at 100-105°C.

The above three points we mentioned should be specific and specific analysis. For an analyst or a technician, although the drying method needs to meet the three requirements, then we only have an oven, and the minion red sample may not meet the requirements. Don't you just measure the moisture in the above three points?

For example, breweries often measure the moisture content of hops, which contain some volatile aromatic oils. This does not meet our first requirement. If oven drying is used, volatile matter and moisture will be lost at the same time, causing analysis errors. In addition, during the drying process, the α-acid in hops partially undergoes chemical reactions such as oxidation, which causes analytical errors. However, the general factory still uses the drying method for measurement, and they generally use low temperature for a long time (80-85°C Bake for 4 hours), or high temperature for a short time (105°C for 1 hour)

Therefore, we should choose the appropriate operating conditions according to our environment and conditions. Of course, we should first understand whether there are errors caused by volatiles and chemical reactions.

3. Determination points of oven drying method

⑴ Sampling (weighing)

Special attention should be paid to prevent changes in moisture when sampling. Some foods such as milk powder and coffee are easy to absorb water, so they must be weighed quickly, otherwise the heavier they are, the heavier they will be.

⑵ Selection of drying conditions

Three factors: ① temperature; ② pressure (atmospheric pressure, vacuum) drying; ③ time.

Generally, 70-105°C can be used for foods that are unstable to heat; 120-135°C can be used for foods that are stable to heat.

4. Operation method

Clean the weighing dish→dry to constant weight→weigh the sample→put into an oven with adjusted temperature (100~105℃)→dry for 1.5 hours→cool in a desiccator→weigh→dry for another 0.5 hour→weigh to constant weight ( The difference between the two weights does not exceed 0.002g, which is the constant weight)

*For fat or high-fat samples, due to fat oxidation, the weight of the subsequent time increases instead, so the weight of the previous time should be calculated.

*For foods that are easy to burn and decompose, you can choose a lower temperature or shorten the drying time.

*For liquid and semi-solid samples, sea sand should be added to the weighing dish to loosen the sample, expand the contact surface for evaporation, and use a glass rod as a container. First put it in a boiling Water Bath to dry until it is almost dry, and then put it in an oven to dry, otherwise the sample without adding sea sand will easily form a layer of film on the surface, making it difficult for water to come out, and the liquid droplets that are easy to boil will cause weight loss.

Calculation: Moisture = G2-G1/W

Solid content (%)=100-moisture %

G1——weighing dish weight after constant weight (g)

G2—weighing dish and sample weight after constant weight (g)

W - sample weight (g)

Solid matter—refers to all residues in the food after water is removed. Its components include protein, fat, crude fiber, nitrogen-free extract and ash.

5. The cause of the error in the oven drying method

⑴The sample contains non-moisture volatile substances (alcohol, acetic acid, essential oils, phospholipids, etc.);

⑵样品中的某些成分和水分的结合,使测的结果偏低(如蔗糖水解为二分子单糖),主要是限制水分挥发;

⑶食品中的脂肪与空气中的氧发生氧化,使样品重量增重;

⑷在高温条件下物质的分解(果糖对热敏感);

果糖C6H12O6大于70℃△→C6H6O3+3H2O

⑸被测样品表面产生硬壳,妨碍水分的扩散;尤其是对于富含糖分和淀粉的样品;

⑹烘干到结束样品重新吸水。

二、真空干燥法

1、原理:利用较低温度,在减压下进行干燥以排除水分,样品中被减少的量为样品的水分含量。

本法适用于在100℃以上加热容易变质及含有不易除去结合水的食品。其测定结果比较接近真正水分。

2、操作方法

准确称2.00~5.00g样品→于烘至恒重的称量皿→至真空烘箱→70℃、真空度93.3~98.6KPa(700~740mmHg)→烘5小时→于干燥皿冷却→称至恒重

计算:水分=G/W

G——样品中干燥后的失重(g)

W——样品重量(g)

真空干燥法测水分,一般用于100℃以上容易变质、破坏或不易除去结合水的样品,如糖浆、味精、砂糖、糖果、蜂蜜、果酱和脱水蔬菜等样品都可采用真空干燥法测定水分。

三、蒸馏法测定水分(迪安—斯达克)

蒸馏发出现在二十世纪初,当时它采用沸腾的有机液体,将样品中水分分离出来,此法直到如今仍在适用。

1、原理:把不溶于水的有机溶剂和样品放入蒸馏式水分测定装置中加热,试样中的水分与溶剂蒸汽一起蒸发,把这样的蒸汽在冷凝管中冷凝,由水分的容量而得到样品的水分含量。

2、步骤

准确称2.00~5.00g样品→于250ml水分测定蒸馏瓶中→加入约50~75ml有机溶剂→接蒸馏装置→徐徐加热蒸馏→至水分大部分蒸出后→在加快蒸馏速度→至刻度管水量不在增加→读数

计算:

水分=V/W

V——刻度管中水层的容量ml

W——样品的重量(g)

3、常用的有机溶剂及选择According to

常用的有机溶剂有比水清的,也有比水重的。

苯甲苯二甲苯CCl4

密度0.880.860.861.59

沸点80℃80℃140℃76.8℃

选择According to:对热不稳定的食品,一般不采用二甲苯,因为它的沸点高,常选用低沸点的有机溶剂,如苯。对于一些含有糖分,可分解释放出水分的样品,如脱水洋葱和脱水大蒜可采用苯,要According to样品的性质来选择有机溶剂。

4、蒸馏法的优缺点

优点:

⑴热交换充分

⑵受热后发生化学反应比重量法少

⑶设备简单,管理方便

缺点:

⑴水与有机溶剂易发生乳化现象

⑵样品中水分可能完全没有挥发出来

⑶水分有时附在冷凝管壁上,造成读数误差

对分层不称心,造成读数误差,可加少量戊醇或异丁醇防止出现乳浊液。

这种方法用于测定样品中除水分外,还有大量挥发性物质,例如,醚类、芳香油、挥发酸、CO2等。目前AOAC规定蒸馏法用于饲料、啤酒花、调味品的水分测定,特别是香料,蒸馏法是的、公认的水分检验分析方法。

四、卡尔—费休法

众所周知,卡尔费休法是测定各种物质中微量水分的一种方法,这种方法自从1935年由卡尔费休提出后,一直采用I2、SO2、吡啶、无水CH3OH(含水量在0.05%以下)配制而成,并且国际标准化组织把这个方法定为国际标准测微量水分,我们国家也把这个方法定为国家标准测微量水分。

1、原理:在水存在时,即样品中的水与卡尔费休试剂中的SO2与I2产生氧化还原反应。

I2+SO2+2H2O→2HI+H2SO4

但这个反应是个可逆反应,当硫酸浓度达到0.05%以上时,即能发生逆反应。如果我们让反应按照一个正方向进行,需要加入适当的碱性物质以中和反应过程中生成的酸。经实验证明,在体系中加入吡啶,这样就可使反应向右进行。

3C5H5N+H2O+I2+SO2→2氢碘酸吡啶+硫酸酐吡啶

生成硫酸酐吡啶不稳定,能与水发生反应,消耗一部分水而干扰测定,为了使它稳定,我们可加无水甲醇。

硫酸酐吡啶+CH3OH(无水)→甲基硫酸吡啶

我们把这上面三步反应写成总反应式为:

I2+SO2+H2O+3吡啶+CH3OH2氢碘酸吡啶+甲基硫酸吡啶

从反应式可以看出1mol水需要1mol碘,1mol二氧化硫和3mol吡啶及1mol甲醇而产生2mol氢碘酸吡啶、1mol甲基硫酸吡啶。这是理论上的数据,但实际上,SO2、吡啶、CH3OH的用量都是过量的,反应完毕后多余的游离碘呈现红棕色,即可确定为到达终点。

I2︰SO2︰C5H5N=1︰3︰10

2、卡尔费休试剂的配制与标定

若以甲醇作溶剂,则试剂中I2、SO2、C5H5N(含水量在0.05%以下)三者的克分子数比例为

I2︰SO2︰C5H5N=1︰3︰10

这种试剂有效浓度取决于碘的浓度。新配制的试剂其有效浓度不断降低,其原因是由于试剂中各组分本身也含有一些水分,但试剂浓度降低的主要原因是由一些副反应引起的,较高消耗了一部分碘。

这也说明了配制这种试剂要单独配,分甲乙两种试剂并且分别贮存,临用时再混合,而且要标定。

甲液I2的CH3OH溶液

乙液SO2的CH3OH吡啶溶液

这种方法对试剂要求严格,要求甲醇、吡啶都是无水的,并且要求有KF水分测定仪(上海化工研究所制)

配制:

称85gI2→于干燥的有塞棕色烧瓶中→加670ml无水CH3OH→塞上瓶塞→振摇使I2全部溶解→加270ml吡啶→混匀→于冰水浴冷却→通干燥的SO2气体60g→塞上瓶塞→于暗处24小时后标定使用

标定:

先加50ml无水甲醇→于反应器中→接通电源→启动电磁搅拌器→用KF试剂滴入甲醇中使甲醇中尚残留的痕量水分与试剂达到终点(即指针到达一定刻度,不记录KF试剂用量)→保持一分钟→用10μl注射器从反应器加料口注入10μl蒸馏水(相当于0.01g水)→电流表指针接近零点→用KF试剂滴定到原定终点→记录

F=G*100/V

F——KF试剂的水当量(mg/ml)

V——KF滴定消耗试剂的体积(ml)

G——水的重量(g)

3、步骤

对于固体样,如糖果需要预先粉碎,称0.30~0.50g样于称样瓶中

取50ml甲醇→于反应器中,所加甲醇要能淹没电极,用KF试剂滴定50ml甲醇中痕量水→滴至指针与标定时相当并且保持1min不变时→打开加料口→将称好的试样立即加入→塞上皮塞→搅拌→用KF试剂滴至终点保持1min不变→记录

计算:

水分=FV/W

F——KF试剂的水当量(mg/ml)

V——滴定所消耗的卡尔费休试剂(ml)

W——样品重量(g)

注:①此法适用于食品中糖果、巧克力、油脂、乳糖和脱水果蔬类等样品;

②样品中有强还原性物料,包括维生素C的样品不能测定;

③卡尔费休法不仅可测得样品中的自由水,而且可测出结合水,即此法测得结果更客观地反映出样品中总水分含量。

④固体样品细度以40目为宜,更好用粉碎机而不用研磨,防止水分损失。

五、水分活度值的测定

食品中水分活度的检验方法很多,如蒸汽压力法、电湿度计法、附感敏器的湿动仪法、溶剂萃取法、扩散法、水分活度测定仪法和近似计算法等。一般常用的是水分活度测定仪法(AW测定仪法)、溶剂萃取法和扩散法。水分活度测定仪法操作简便,能在较短时间得到结果。

1、AW测定仪法

⑴原理:在一定温度下主要利用AW测定仪中的传感器According to食品中水的蒸汽压力的变化,从仪器的表头上读出指针所示的水分活度。在样品测定前需用氯化钡和溶液校正AW测定仪的AW为9.000。

⑵步骤

①仪器校正

两张滤纸→浸于氯化钡饱和液中→用小夹子轻轻地把它放在仪器的样品盒内→然后将传感器的表头放在样品盒上,轻轻地拧紧→于20℃恒温烘箱→加热恒温3小时后→将校正螺丝校正AW为9.00

②样品测定

取样→于15~25℃恒温后→(果蔬样品迅速捣碎取汤汁与固形物按比例取样→肉和鱼等固体试样需适当切细)→于容器样品盒内→将传感器的表头置于样品盒上轻轻地拧紧→于20℃恒温烘箱中→加热2小时后→不断观察表头仪器指针的变化情况→等指针恒定不变时→所指的数值即为此温度下试样的AW值

2、溶剂萃取法

⑴Principle: Water in food can be extracted with immiscible solvent benzene. The amount of water extracted by benzene at a certain temperature varies with the water activity in the sample, that is, the amount of extracted water is proportional to the water activity in the water phase. The ratio of water in the sample is the water activity of the sample.

⑵ steps

Weigh 1.00g of sample → put in 250ml ground-mouth Erlenmeyer flask → add 100ml of benzene → cork the bottle → shake for 1 hour → stand for 10 minutes →

Aspirate 50ml → put in Karl Fischer moisture analyzer → add 70ml of anhydrous methanol → mix → drop to reddish with KF reagent → set the battery

When the stream pointer remains unchanged, it is the end point → record

Find the saturated dissolved water value in benzene:

Take 10ml of distilled water instead of the sample → add 100ml of benzene → shake for 2 minutes → stand for 5 minutes → measure the same sample as above

⑶ Calculation

AW=[H2O]n×10/[H2O]0

AW——water activity value in the sample

[H2O]n——the amount of water extracted from food, that is, the number of milliliters of KF reagent consumed from the KF reagent titer multiplied by the titration sample

[H2O]0——Determination of the amount of extracted water in pure water

3. Diffusion method

After the sample is diffused and balanced in the higher and lower standard saturated solutions in the Convey micro-diffusion dish sealed and at constant temperature, the AW value in the sample is calculated according to the increase and decrease of the sample weight.

6. Other methods of measuring moisture

1. Chemical drying method

The chemical drying method is to put a chemical that has a strong adsorption effect on water vapor and a water sample into a desiccator (glass or vacuum desiccator), and make the sample reach a dry constant weight through isothermal diffusion and adsorption, and then according to The moisture content can be calculated from the weight loss of the sample before and after drying. This method takes a long time to dry at room temperature, several days, dozens of days or even months.

Desiccants include phosphorus pentoxide, barium oxide, magnesium perchlorate, zinc hydroxide, silica gel, chlorine oxide, etc.

2. Microwave method

Microwave refers to electromagnetic waves with a frequency range of 103 to 3×105 MHZ. When microwave passes through a water-containing sample, the energy loss caused by moisture is far greater than the loss caused by dry matter, so the water content of the sample can be obtained by measuring the loss of microwave energy.

3. Infrared absorption spectroscopy

Infrared rays belong to electromagnetic waves, light with a wavelength of 0.75 to 1000 μm. The infrared band can be divided into three parts:

① near infrared region 0.75 ~ 2.5μm;

②Mid-infrared region 2.5~25μm;

③Far infrared region 25~1000μm.

According to the fact that there is a certain relationship between the degree of moisture absorption of infrared light of a certain wavelength and its content in the sample, a method for determining moisture by infrared spectroscopy is established.

- 1Moisture meter type and application

- 2Moisture determination procedure of high-low constant temperature drying method

- 3Standard operating procedure for moisture determination

- 4Rapid oven moisture determination

徐厥通; 陈诗斌 - 《快速烘箱水分测定法》

- 5Evaluation and analysis of uncertainty of micro-Moisture Analyzer measurement results by Fischer method

郭洪波 - 《卡尔费休法微量水分测定仪测量结果不确定度评定》