How to choose a suitable painting Thickness Gauge?

The thickness of the anti-corrosion paint film is different from the thickness of the ordinary decorative paint film, and the thickness of the anti-corrosion paint film often determines the service life of the anti-corrosion system. Both theoretical calculations and specific test results show that the life of the coating increases with the thickness of the coating. Increasing the thickness of the coating can strengthen the isolation ability of the coating, which is an effective means to improve the life of the coating. Therefore, the thickness of the paint film is one of the important indicators of anti-corrosion coating quality inspection, enterprises have made clear provisions on the thickness of the paint film on the surface of the product, and the coating thickness measurement has also become an important part of the processing industry and surface engineering quality inspection, and it is the means required for the product to achieve excellent quality standards. With the continuous advancement of measurement technology, coating thickness testing instruments have been widely used in all walks of life, and they are also very fast to use. However, how to choose measuring instruments and use them correctly is still a problem faced by some enterprises.

An overview of coating thickness inspection methods

The main measurement methods of coating thickness include wedge cutting method, light interception method, electrolysis method, thickness difference method, weighing method, X-ray fluorescence method, β-ray backscattering method, capacitance method, magnetic measurement method and eddy current measurement method. Wedge cutting method, light truncation method, electrolysis method, thickness difference method, weighing method is destructive testing, that is, the coating needs to be destroyed during measurement, and the measurement means are cumbersome, the speed is slow, and it is mainly used for sampling inspection. Both X-ray and β-ray methods are non-contact, non-destructive measurements, but the measuring devices are complex and expensive, and the measuring range is small. Because radiation requires a radioactive source, it is also necessary to comply with radiation protection norms. X-ray method can measure extremely thin coating, double coating, alloy coating; The β-ray method is suitable for coating and substrate atomic number measurement greater than 3. Capacitance measurements have a very limited range of application and are only used for thickness measurement of the insulation layer of thin conductive conductors. With the increasing progress of science and technology, especially the introduction of microcomputer technology in recent years, the magnetic and eddy current Thickness Gauges have developed in the direction of miniature, intelligence, multi-function, high precision and practicality. Magnetic and eddy current Thickness Gauges now measure with a resolution of 0.1 μm and an accuracy of 1 percent, which is a significant improvement. Magnetic and eddy current Thickness Gauges are widely used in industry and scientific research due to their wide range of applications, wide measuring ranges, easy operation, low price, and non-destructive testing. The non-destructive method is used to detect the thickness without destroying either the coating or the substrate, and the detection speed is fast, which can make a large number of inspection work economical. Remember: the method of non-destructive thickness testing can be applied to the production site for quality control.

Principle and instrument of non-destructive testing of thickness

Although X-ray fluorescence, β-ray backscatter, magnetic measurement, and eddy current measurement are all non-destructive tests, magnetic measurement and eddy current measurement are suitable for painting production sites.

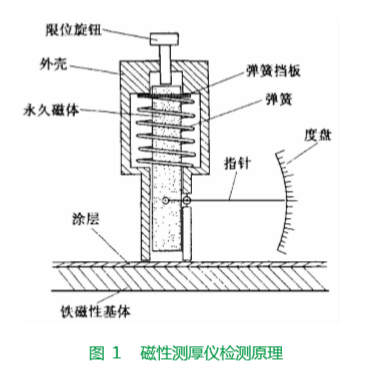

Magnetic attraction measurement principle and Thickness Gauge

Magnetic attraction measurement is a kind of magnetic measurement method, which is made by using the principle that the suction force between two magnetic materials is proportional to the distance. Using this principle, a Thickness Gauge can be measured as long as the difference in permeability between the coating and the substrate is large enough. As shown in Figure 1, the amount of suction between the long-lasting magnet (probe) and the magnetically conductive steel is proportional to the distance between the two, which is the thickness of the coating. The thinner the coating, the greater the magnetic attraction and the greater the displacement of the long-lasting magnet; The thicker the coating, the less magnetic attraction and the less displacement of the long-lasting magnet. Since most industrial products use magnetically permeable steel, magnetic Thickness Gauges are widely used. The basic structure of the magnetic suction Thickness Gauge is composed of a long-term magnet, a spring, a ruler and a self-stop mechanism. After the magnet is engaged with the measured object, the measuring spring is gradually elongated behind it, and the tensile force gradually increases. When the tensile force is just greater than the suction force, the thickness of the coating can be obtained by recording the amount of tensile force at the moment when the magnet detaches. The new magnetic attraction Thickness Gauge can automatically complete this recording process, different models have different ranges and applicable occasions, and the instrument is easy to operate, sturdy and durable, does not need to be powered, no need to calibrate before measurement, and the price is low, so it is very suitable for on-site quality control in the workshop.

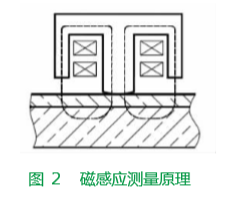

Magnetic induction measurement principle and magnetic Thickness Gauge

Magnetic induction measurement is also a kind of magnetic measurement, the principle is that the magnetic resistance of non-magnetic materials is proportional to its thickness, according to the magnetic flux from the probe through the non-ferromagnetic coating and into the ferromagnetic matrix to determine the coating thickness, can also be measured by the corresponding magnetic resistance size to express its coating thickness. As shown in Figure 2, when the probe is in contact with the coating, the probe and the magnetic metal matrix form a closed magnetic circuit, and the magnetic circuit reluctance changes due to the presence of the non-magnetic coating, and the thickness of the coating can be derived by measuring the change. The thicker the coating, the greater the magnetic resistance and the lower the magnetic flux. Thickness gauges that use the principle of magnetic induction generally require the permeability of the substrate to be more than 500. If the material of the coating is also magnetic, the difference in the permeability to the substrate is large enough (e.g. nickel plating on the surface of steel). When a probe with a coil around the soft core is placed on the coating to be measured, the instrument automatically outputs a test current or a test signal. Early products used an analog meter to measure the magnitude of the induced electromotive force, and the instrument amplifies this signal to indicate the thickness of the coating. In recent years, new technologies such as frequency stabilization, phase locking, and temperature compensation have been introduced into circuit design, and magnetoresistance has been used to modulate measurement signals, and integrated circuits and microcomputers have been introduced to improve measurement accuracy and reproducibility by nearly 1 order of magnitude. Modern magnetic Thickness Gauges with a resolution of 0.1 μm, a permissible error of 1% and a measuring range of 10 mm. Magnetic Thickness Gauges can be used to accurately measure paints, plastics, rubber coatings, porcelain and enamel protective layers on steel surfaces, as well as a variety of non-ferrous metal coatings, including nickel-chromium, and various anti-corrosion coatings in the petrochemical industry.

Principle of eddy current measurement and proximity current Thickness Gauge

A high-frequency alternating current is used to generate an electromagnetic field in the coil, and when the probe is in contact with the coating, eddy currents are generated on the metal substrate. It also produces feedback on the coil in the probe, and derives the thickness of the coating by measuring the magnitude of the feedback action, which works as shown in Figure 3. The closer the probe is to the conductive substrate, the greater the eddy current and the greater the reflected impedance. This feedback effect characterizes the distance between the probe and the conductive substrate, i.e. the thickness of the non-conductive coating on the conductive substrate. Thickness gauges made according to the principle of eddy current measurement are called eddy current Thickness Gauges. Because eddy current Thickness Gauge probes are specifically designed to measure the thickness of coatings on non-ferromagnetic metal substrates, they are referred to as non-magnetic probes.

It also produces feedback on the coil in the probe, and derives the thickness of the coating by measuring the magnitude of the feedback action, which works as shown in Figure 3. The closer the probe is to the conductive substrate, the greater the eddy current and the greater the reflected impedance. This feedback effect characterizes the distance between the probe and the conductive substrate, i.e. the thickness of the non-conductive coating on the conductive substrate. Thickness gauges made according to the principle of eddy current measurement are called eddy current Thickness Gauges. Because eddy current Thickness Gauge probes are specifically designed to measure the thickness of coatings on non-ferromagnetic metal substrates, they are referred to as non-magnetic probes.

Compared with the principle of magnetic induction, the principle of eddy current measurement is different in the probe, the frequency of the signal, the magnitude of the signal, and the scale relationship. However, like magnetic induction Thickness Gauges, eddy current Thickness Gauges have a resolution of 0.1 μm, a permissible error of 1%, and a range of 10 mm. In principle, the Thickness Gauge using the eddy current principle can measure the non-conductive coatings on all conductors, such as paints, plastic coatings and anodized films on the surface of aerospace vehicles, automobiles, home appliances, aluminum alloy doors and windows and other aluminum products. For coating materials with certain conductivity, it can also be measured by calibration, such as chrome plating on copper, but the ratio of conductivity between the two is required to be at least 3 ~ 5 times different. Although the steel substrate can also conduct electricity, it is more appropriate to use the magnetic principle to measure the coating on the surface of the steel substrate. With the development of various new engineering materials, the application of microelectronics technology and the advancement of standardization, the eddy current coating Thickness Gauge has made continuous breakthroughs and innovations in circuit design, multi-standard and versatility of probes, new sensor applications, value display and data printing, measurement and control function expansion and intelligence, etc., and eddy current thickness measurement technology has developed rapidly.

Selection of coating Thickness Gauges

Coating Thickness Gauges that can be used for on-site inspection

The dry film thickness of the paint film is generally specified in the coating process, so the paint film thickness needs to be tested in production, and the spraying process is adjusted or reworked and repaired to achieve the required thickness of the process. As a kind of quality inspection and control instrument, the coating Thickness Gauge used by the enterprise needs to be able to carry out on-site inspection and not cause damage to the product as much as possible. The measurement of coating dry film thickness is divided into two methods: destructive test and non-destructive test. Destructive test methods should be destructive behaviors such as scratching on the paint film, and non-destructive test methods and non-destructive testing methods will not cause damage to the paint film. Non-destructive, non-destructive measurement methods are generally used, and destructive testing methods are used only when disputes arise or arbitration is required. At present, there are many instruments and methods for measuring dry film thickness, but each method has certain limitations, and there are very few measurement methods and instruments that can be applied to all coatings and environments. Magnetic Thickness Gauges and eddy current Thickness Gauges are two commonly used non-destructive testing instruments, both of which are suitable for coating the surface of metal substrates, but magnetic Thickness Gauges are suitable for magnetic permeable metal substrates, while eddy current Thickness Gauges are suitable for the detection of anti-corrosion layers on the surface of conductive metal substrates. Magnetic and eddy current gauges are very small in size and mass, making them easy to carry. It should be pointed out that neither magnetic Thickness Gauges nor eddy current Thickness Gauges can be used to measure the thickness of anti-corrosion coatings on the surface of non-metallic substrates such as concrete

The structure of the coating Thickness Gauge

Coating Thickness Gauges generally include probes or probes, machine bodies, and output devices, but there are great differences in the shape, structure, and size of coating Thickness Gauges produced by different manufacturers, and different models of Thickness Gauges produced by the same manufacturer are also different, as shown in Figure 4. For paint Thickness Gauges used in field inspections, a portable Thickness Gauge with a lighter weight should be chosen. The vast majority of portable coating Thickness Gauges have data storage or data printing capabilities, and can also be connected to a computer through a data line for data copying, statistics, analysis, etc. Therefore, the smaller the size of the instrument used in the field, the better, and it is easy to carry.

Description of the main technical parameters

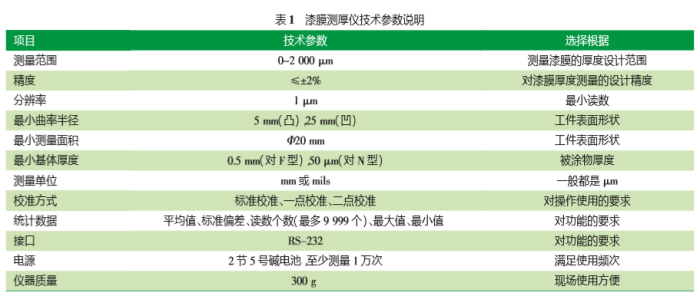

When selecting a coating Thickness Gauge, you should pay attention to the technical parameters such as the measurement range and the allowable error, as detailed in Table 1.

Selection of coating Thickness Gauges

The parameter choices in Table 1 can have different emphases for different companies. For example, the minimum radius of curvature, if the products produced by the enterprise are flat, there is no need to pay attention, but for the production of round or cylindrical small parts or products, it is necessary to choose a coating Thickness Gauge with a small enough radius of curvature of the convex surface. Another example is the construction machinery manufacturer, because the products are made of thick plates, it is of no practical significance to pay attention to the minimum thickness of the substrate. At present, there are many coating Thickness Gauges that can be bought in the domestic market, not only domestic brands such as Times and Deaoshun, but also a large number of foreign brands such as KETT in Japan, BYK, EPK, ERICHSEN in Germany, Defelsko and LEE in the United States. Different brands and models of coating Thickness Gauges are different in function, structure, appearance and quality, which can be queried through the company's website or domestic agents. As a coating Thickness Gauge used in the coating production site, it should be selected portable, that is, light weight; In order to ensure the authenticity of the data, it should have the function of on-site printing; In addition, in order to carry out the analysis of the test data, the coating Thickness Gauge used in the coating production site should have a data storage function and a computer data interface, which can transmit the test data to the computer on a regular basis, and summarize, sort out and analyze the data. Of course, some coating Thickness Gauges have statistical functions such as average, standard deviation, number of readings, maximum value, minimum value, etc. Enterprises can choose the appropriate coating Thickness Gauge according to their own needs and usage habits. In addition, there is a huge price gap between imported brands and domestic brands, and enterprises can choose according to their own conditions.

The use of paint Thickness Gauges

Even with the same coating Thickness Gauge, there may be great differences in the data measured by different people or on the same coating on different types and states of substrates, which is caused by the factors of the measuring personnel, the substrate material, thickness, surface condition and measurement position of the measurement film. Therefore, when using a Thickness Gauge to inspect the thickness of a coating, it is not only necessary to operate it correctly, but also to adjust it to the specific substrate.

Read the instrument instruction manual carefully before use Different manufacturers and different brands of instruments are different in terms of structure, buttons, calibration, etc., so you need to read the instrument instruction manual carefully before use to avoid errors in measurement data caused by misoperation.

Pay attention to the metal substrate material

The magnetic properties and conductivity of different metal matrix materials are different, which will affect the measurement results. In order to avoid the influence of heat treatment and cold working factors, the instrument should be calibrated with a standard piece with the same properties as the base metal of the specimen, and the specimen to be coated can also be used for calibration. Due to the different electrical conductivity of the base metal due to its different composition and heat treatment methods, the instrument should be calibrated using a standard piece with the same properties as the base metal of the test piece.

Pay attention to the shape of the test piece

In actual production, there are differences in material thickness, shape, surface roughness, etc., which can affect the actual measurement results. Each instrument has a critical thickness of the base metal, greater than this thickness, the measurement is not affected by the thickness of the base metal, if the thickness of the specimen material is less than the critical thickness required by the instrument, the test result will be different from the actual thickness. Some instruments are very sensitive to the steep changes in the surface shape of the specimen, so the number of measurements taken close to the edge of the specimen or the inner corner of the specimen will be unreliable, and the actual measurement should be selected away from the edge and the inner corner. There is not only a steep change in shape on the surface of the specimen, but also different curvatures, and the measurement results of some instruments always increase significantly with the decrease of the radius of curvature. Therefore, even if the minimum radius of curvature is taken into account when selecting the instrument, the measurement should still be carried out in a flat area as much as possible. The above is also the reason why the minimum radius of curvature, the minimum measuring area, and the minimum substrate thickness need to be considered when choosing a thickness measuring instrument. In addition, in actual production, the surface roughness of different workpieces is not the same. The greater the roughness, the greater the impact on the measurement results of some instruments. Rough surfaces can cause systematic and accidental errors, and each time a measurement is taken, the number of measurements should be increased at different positions to overcome this accidental error. This point is not pointed out in the manuals of many manufacturers. We used domestic and imported Thickness Gauges to calibrate the surface after shot blasting on a flat surface, and the readings ranged from 10 ~ 30 μm. That is to say, if this method is followed, the measured data will be 10 ~ 30 μm larger than the actual thickness of the paint film, that is, the actual thickness of the paint film can not meet the design requirements. Therefore, if the base metal is rough, it is also necessary to take several positions on the uncoated base metal specimen with similar roughness to calibrate the zero point of the instrument; Or dissolve and remove the coating with a solution that does not corrode the base metal, and then calibrate the zero point of the instrument. Of course, when the thickness of the paint film is 5 ~ 6 times the surface roughness of the substrate, the roughness can be ignored. In short, the calibration of the instrument needs to be carried out according to the surface roughness of the coated workpiece on site

Detect the environment

The strong magnetic field generated by various electrical equipment around will seriously interfere with the magnetic thickness measurement work, and should be kept away from the strong magnetic field environment as far as possible when using.

operate

Some instruments are sensitive to adhesion materials that prevent the probe from coming into close contact with the paint film surface, so it is necessary to remove the adherent material to ensure that the instrument probe is in direct contact with the surface of the test piece. The amount of pressure applied by the probe to the test piece affects the measured reading, so it is important to keep the pressure constant. The way the probe is placed also has an impact on the measurement, where the probe should be kept perpendicular to the specimen surface. In addition, it is often not the same for each reading, so several more readings are required for each measurement area. Local differences in the thickness of the paint film also require multiple measurements in any given area, especially when the surface is rough.

epilogue

Enterprises should choose suitable coating thickness measuring instruments such as measurement range and measurement accuracy according to the material and coating requirements of their own products, and be proficient in the use and calibration methods of the instrument, and use them correctly according to the specific situation in the actual measurement. Only in this way, the use of coating Thickness Gauge can really play a role in the detection and control of coating thickness, so that the thickness of the paint film and the anti-corrosion performance of the coating can truly meet the design requirements.

- 1Selection and comparison of several domestic (CN) magnetic metal substrate Thickness Gauges

- 2American Defelsko PosiTector 6000 Coating Thickness Gauge probe characteristic parameter selection

- 3Difference and comparison of Lantai Thickness Gauge CM8822, CM8821 and CM8820

- 4Positector200 Ultrasonic Thickness Gauge measurement of coated Film thickness on concrete and masonry substrates

- 5Talking about powder coated Film thickness measurement and paperless technology

- 6Coating Film thickness determination method

- 7PosiTector 6000 FNS1 Thickness Gauge Unpacking Real Shot Evaluation

- 8One article allows you to easily choose Lantai Thickness Gauge

- 9Technical Comparison of 4 PosiTector200 Ultrasonic Thickness Gauges