Hazards of metal corrosion and their classification

金属对于人类的重要性是人所共知的常识。可以说没有金属就没有现代的人类文明。

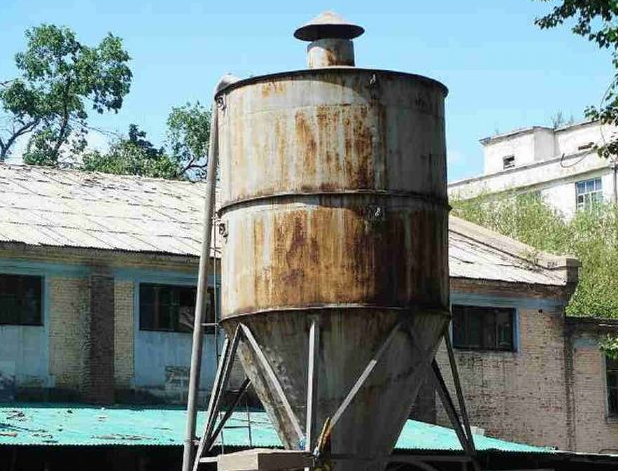

当金属与其周围的介质发生化学反应或电化学反应以后,就会形成金属的化合物,使金属失去了原有的光泽、强度、韧性等,金属便受到了破坏,这就是金属腐蚀。

金属腐蚀问題遍及国民经济和国防建设的各个部门。在绝大多数情况下,腐蚀是破坏性的,其所造成的损失是极为严重的。据国外统计,每年由于腐蚀而报废的金属设备和材料达100Mt以上。许多国家在各自国内腐蚀的调查中,发现由于腐性而造成的经济损失高达国民经济总产值的3%~4%,这是十分惊人的。因此,各国的腐蚀工作者都对腐蚀的研究极为重视,针对腐蚀情况,积极采取各种防护措施,以尽量减少腐蚀造成的损失。

金属腐蚀的分类

金属腐蚀一般可分为化学腐蚀和电化学腐蚀两大类。

1、化学腐蚀

化学腐蚀是由表面.与介质发生化学作用而引起的,它的特点是在作用进行过程中没有电流产生。化学腐蚀可分为以下两类。

(1)气体腐蚀金属在干操气体中(表面上没有湿气冷凝)发生的腐蚀。气体腐蚀一般是指在高温时金属的腐蚀,例如轧钢时生成的氧化皮,内燃机活塞的烧坏等。

(2)在11l三电解质溶液中的腐蚀金属在不导电的液体中发生的腐till。例如金属在有机液体(如乙醇、石油等)中的腐蚀。

2、电化学腐蚀

电化学腐蚀是出金属表面.与介质发生电化学作用而引起的,在作用过程中有阴极区和阳极区,在金属与介质中有电流流动。电化学作用有时単独造成腐蚀,有时有机械作用、生物作用共同产生腐蚀。电化学腐性可分为以下几类。

(1)大气腐蚀金属在潮湿的空气中发生的腐蚀。

(2)土壤腐蚀理设在地下的金属构件(如管道、电缆等)所产生的腐蚀。

(3)在电解质溶液中的腐蚀这是非常广泛的一类腐蚀。天然水.及大部分水溶液对金属结构的腐蚀(例如在海水和酸、碱、盐的水溶液中所发生的腐蚀)都属f这一类。

(4) Corrosion in molten salt Corrosion of metals in molten salt. For example, in the heat treatment workshop , the corrosion of the electrode and the metal to be processed in the molten salt heating furnace.

(5) Stress corrosion cracking is metal corrosion damage under the action of tensile stress and corrosive medium. Stress comes from residual stress or external stress during hot and cold processing. The cracks of cracking are perpendicular to the tensile stress, sometimes cracking along the grain boundaries of metal crystals, and sometimes transgranular cracking.

(6) Corrosion fatigue is under the combined action of alternating stress (or pulse stress) and corrosive medium, the fatigue limit of metal is greatly reduced, which leads to premature rupture (such as screw industry shaft, pump shaft) corrosion.

(7) Wear and corrosion (abrasion) There are corrosion and mechanical wear at the same time, and the two accelerate each other. Wear and tear can take many forms.

① Impact corrosion (erosion) is caused by liquid flow or impact.

② Cavitation corrosion (cavitation erosion) High-speed flowing liquid, due to irregular flow, produces so-called cavitation. There is only a little water vapor or low-pressure air in this cavity. Due to the frequent changes in pressure and flow conditions, the cavity will periodically appear and disappear. The so-called "water hammer effect" occurs on the metal surface of the damaged metal surface, which often destroys the protective film on the metal surface and causes the corrosion to continue to deepen.

③ Fretting corrosion is the wear caused by the mutual vibration of two adjacent surfaces, which destroys the protective film of the metal and accelerates the corrosion.

(8) Microorganisms corrode the life activities of certain microorganisms, which can promote the electrochemical reaction in the anode or cathode area, or weaken the corrosion resistance of the metal surface film, or produce corrosive substances, thereby accelerating electrochemical corrosion. Such as sulfate reducing bacteria and iron bacteria on metal corrosion.

(9) Corrosion of marine organisms Many marine organisms (animals or plants) can adhere to the metal surface and reproduce continuously, and can produce corrosive substances during their metabolism, or cause oxygen concentration due to uneven cover on the metal surface. Poor battery, thus accelerating electrochemical corrosion.