Design and Application of Metering rod Spreader

In recent years, the production of coating machines has achieved great development in the world. Many new coated paper factories have been built, and some paper mills have also established coated paper workshops or added coating devices to existing paper machines. Improve the appearance quality and printing performance of coated printing paper, so that it can produce higher printing paper with inferior raw materials.

Some paper mills in my country that produce coated paper have decades of production history, but they are still relatively backward in terms of equipment, the output cannot meet market requirements, and the quality and variety cannot compete with foreign coated paper. With the rapid development of the national economy and the improvement of people's living standards, the demand for coated paper will continue to increase day by day, and there will be higher requirements for the quality and variety of products.

Metering rod coating is to pre-coat a layer of covering layer on the surface of base paper or cardboard, so as to lay a good foundation for the next coating, so as to improve the surface quality of paper and improve the uniformity of coating. The metering bar coating device is mainly composed of four parts: metering bar, coating roller, coating tank, and transmission control.

It is usually used in conjunction with metering rod and air knife coating. This coating is usually divided into two forms: one is installed in the drying part of the paper machine, and the other is a separate coating machine outside the paper machine (export Bangladeshi is the first form).

Since the coating amount of the metering rod is very low, it can only be used as a pre-coating device. Therefore, a smooth rod can make the surface of the coated paper smooth and smooth. If it is used in conjunction with air knife coating, it will significantly improve coating quality.

1. Metering rod structure and principle

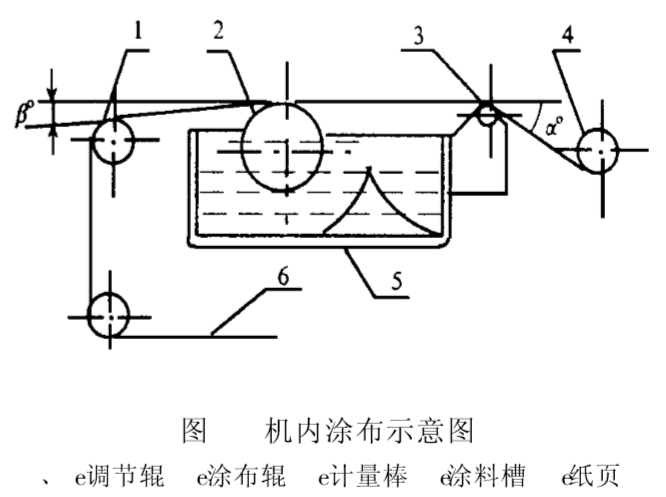

When the metering rod coating is used in the board machine, the coating inside the machine is shown in Figure 1

The paper sheet is coated with paint on the original paper surface by the distribution roller, and the excess paint is scraped off by the counter-rotating metering rod. The size of the angle is controlled by adjusting the roller to control the grammage of the paint remaining on the paper surface to achieve the required coating amount. Adjusting the size of the β angle by controlling the adjusting roller can change the feeding amount of the coating roller.

The coating roller and the metering rod are equipped with separate transmissions. The coating roller and the paper sheet can rotate in forward and reverse directions, and the speed can be adjusted according to the amount of coating. The speed adjustment range is 1/ of the paper speed. 3 or so. The metering rod is also driven separately (AC frequency conversion motor). In order to prevent torsional deformation caused by the length of the rod, both ends of the rod are driven by a first-stage deceleration mechanism, and the rotation accuracy of the rod can also be improved. The material of the metering rod is special magnetic stainless steel with a diameter of 8mm and the outer surface is chrome-plated. The bracket is made of ultra-high molecular material, and a water hole is provided at the bottom of the metering rod for cleaning the surface of the metering rod, and a magnet is also provided at the bottom of the rod to prevent the metering rod from jumping when it is working. The coating tank is made of stainless steel, and there are feeding ports and feeding ports at both ends of the tank. A partition is arranged outside the metering rod to separate from the paint cavity, so that the scraped paint can be separated from the paint in the paint tank. The coating roller is 200mm steel pipe, the outer layer is chrome-plated, and the transmission side is equipped with transmission control.

2. Control and use of metering bar coating amount

The amount of coating on the metering rod depends on the following factors:

①The tension of the paper web;

②The concentration of the paint;

③The control of the α angle, the coating amount decreases when the α angle increases, otherwise the coating amount increases;

④The range of the β angle of the paper in front of the coating roller;

⑤The rotation direction of the coating roller . When it rotates against the direction of the paper, the coating amount is large; otherwise, it is small.

Since the use of the metering rod can only be used as a pre-coating equipment, the coating amount is usually 5-8g/m2, therefore, the metering rod cannot be used alone, and the combined use of the metering rod and the air knife can obviously improve the coating quality. Although the speed of the metering rod has little to do with the speed of the paper machine, the metering rod coating can only be applied when the speed of the paper machine is about 0-150m/min. Because the coating amount is not easy to control when the vehicle speed is high, especially when the vehicle speed is high, the coating is prone to streaks and scratches, which is mainly due to the difficulty in keeping the surface of the scraping roller clean. In addition, it is also very important to control the concentration of the coating and the dryness of the paper before coating. Generally, the dryness of the coated paper is 95%, and the dryness of the coated paper is 80% to 85%.

Production practice shows that adding a Drying Oven or far-infrared drying after metering bar coating and before air knife coating can make the coating on the paper surface after precoating solidify quickly, which is more conducive to the production effect of air knife coating. In short, metering bar coating has the characteristics of small size, light weight, compact structure, etc., and has the advantages of less investment, quick results, and energy saving.

3. Customized tools for metering rods

- 13 minutes to let you know several Spreader methods

- 2Coating Metering rodsFAQ

- 3Coating Metering rod: Mayer-Rod

- 4

- 5Cleaning, maintenance and service life prediction of coated measuring rods

- 6Analysis of Advantages and Disadvantages of Mayer Wire Bar Coater

- 7Explanation of the principle and structure of the wire rod applicator

- 8How to choose these experimental coating equipment?

- 9Why are paper coaters and converters transitioning to forming metering grooves?