Film thickness test method - eddy current method

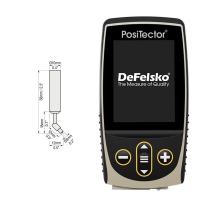

The eddy current Thickness Gauge uses a probe with a high-frequency coil to generate a high-frequency magnetic field, so that eddy currents are generated in the sample to be tested under the probe. The amplitude and phase of this eddy current is a function of the thickness of the non-conductive coating between the probe and the sample under test . Coating thickness can be read directly from the measuring instrument.

This method can measure the thickness of non-conductive coatings on non-magnetic metal substrates (such as the thickness measurement of aluminum anodized film), single-layer metal coatings on non-conductors, and the thickness of plating (coating) layers with large conductivity differences between non-magnetic substrates and coatings. . The factors affecting the measurement accuracy are similar to those of the magnetic method. Eddy current thickness measurement is not only affected by the conductivity of the substrate, the thickness of the substrate, and the thickness of the coating, but also by the curvature of the sample, surface roughness, edge effects, and the pressure on the probe. The test error is within 10% . The measurement accuracy of coatings with thickness less than 3 μm is low.

- 1Aluminum Panel platings thickness measurement

- 2Selection skills of handheld coating Thickness Gauge

- 3Film thickness arbitration method - metallographic method

- 4How to calculate Film thickness?

- 5Electroplated coating mass detection and evaluation method

- 69 important performances of Armoloy Chromium

- 7Determination of Bonding Strength of Hard Coating by Automatic Scratch meter

张平余;刘洪;王秀娥;顾则鸣;侯企贤;肖永东 - 《摩擦学学报》

- 8Film thickness measurement method of magnetic coating

- 9Film thickness test method overview