Beijing Times TH134 Integrated Richter Hardness Instrument Operation Instructions

Chapter 1 Introduction

1.1 Overview

Times TH134 integrated Leeb Hardness Tester (hereinafter referred to as Hardness Tester) is a professional integrated hardness testing instrument, which has the advantages of compact structure, high measurement accuracy, wide measurement range, easy to carry and easy to operate, etc. It is mainly used for testing steel , Cast steel, especially suitable for testing deep grooves (within depth 49mm and width above 4.2mm) and profiles (such as tooth surfaces) until the test piece.

The Hardness Tester integrates DL1 impact device and data processing device. Can convert Brinell, Vickers, Rockwell B or Shore hardness values, and can choose five impact directions.

If it is connected with Times TA210 micro-printer, online printing and offline printing can be realized. and can

communicate with the computer.

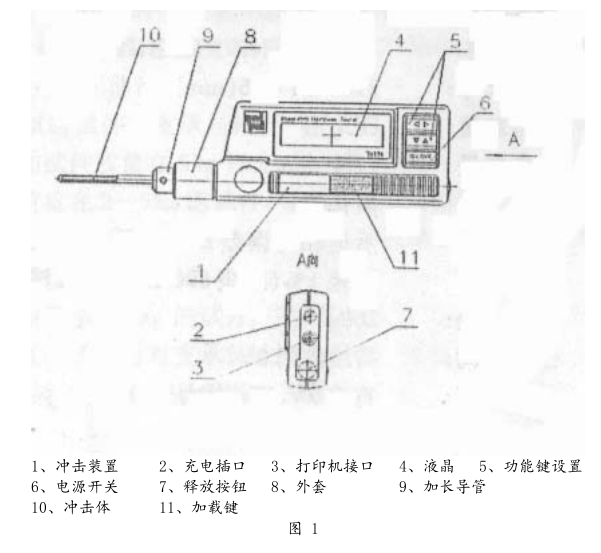

1.2 Shape and structure

The outline structure of Times TH134 integrated Leeb Hardness Tester is shown in Figure 1.

1.3 Main purpose

Direct measurement of large and/or heavy test pieces

Installed machinery or permanently assembled components

Material classification of metal material warehouse

Small spaces with large workpieces, etc.

It is more suitable for measuring parts such as the bottom of deep grooves or profiles (such as tooth surfaces)

1.4 Technical parameters

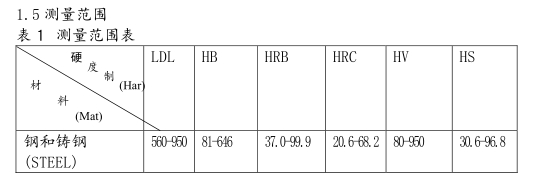

Hardness system: LDL, HB, HRC, HRB, HV, HS

Dimensions: 210×24×55(mm)

Impact device: DL1 type

Impact energy: 11Nmm

Ball head: Tungsten carbide

Accuracy: relative error of indication value ± 1%; relative error of indication value repeatability 1% (corresponding to 890LDL standard test block)

Weight: 200g

Working time: continuous use 8h

Charging time: DC 9V, 75mA more than 8h

Impact direction: ↓+90°;↙+45°;←0°;↖-45°;↑-90°

Working temperature: 0~45℃

Chapter 2 Preparation of Specimen

2.1 Overview

In order to reduce the influence of the surface roughness of the test piece on the measurement results, the surface to be tested should be smooth, the surface roughness Ra value should not exceed 2.5 μm, and the surface of the test piece should be clean and free of oil.

2.2 The support and coupling of the specimen during the test

If the mass of the specimen is more than 5kg, no support is required.

For specimens with a mass of 2-5kg, specimens with overhanging parts and thin-walled specimens, when testing, use

Objects with a mass greater than 5kg are firmly supported to avoid bending deformation and movement of the test piece caused by the impact force.

For the test piece with a mass less than 2kg, it should be tightly coupled with the support body greater than 5kg.

The surface and the surface of the supporting body should be flat and smooth, and there should be no excess coupling agent, and the test direction should be perpendicular to the coupling surface.

The mass of the test piece should not be less than 0.1kg, the minimum thickness should not be less than 5mm, and the depth of the hardened layer should not be less than 0.8mm.

The clamping face of the fixture shall be perpendicular to the direction of testing.

When the test piece is a large-area plate, long rod, or curved workpiece, even if the mass and thickness are large, it may still cause deformation and instability of the test piece, resulting in inaccurate measured values. Therefore, the back of the test point should be reinforced or supported. The test piece itself cannot be magnetic.

Chapter 3 Operation Method

Chapter 4 Maintenance and Repair

4.1 Maintenance

The Hardness Tester should not be subjected to impact and heavy pressure as much as possible, and should not be placed in a strong magnetic field or in a humid environment, and should not be stained with oil. When the Hardness Tester is not in use, be sure to release the impact spring! cleaning catheter

After the measured value is 1000-2000 times, clean a catheter and impact body with a soft and long nylon brush, unscrew the extended catheter and take out the impact body, use the nylon brush that comes with it to rotate the catheter counterclockwise, and then Gently pull it out, repeat this 5-6 times, and then install the impact body and the extended catheter.

Do not use any lubricant between the guide tube and the impact body!

Charge

Charge according to the following method: After working with the internal power supply for 8 to 12 hours, it should be charged, and the charging time is more than 8 hours.

The battery in the Hardness Tester is a Ni-Cd battery, which can generally be used for 2 years. If the battery is damaged, you can go to the Times Service Center to replace it with a new one. Do not open the machine by yourself!

Calibration with standard test block

The Hardness Tester can be calibrated by using the standard hardness test block that comes with it, that is, when the value is marked on the standard test block, the error between the arithmetic mean of the five-point test and the standard value does not exceed ±12LDL, that is, when the value is marked on the test block, The error between the displayed value and the block value does not exceed ±12LDL.

Depending on the hardness scale and the test piece, after 3,000 to 12,000 measurements, the wear of the ball head of the impact body may lead to inaccurate measured values. At this time, you can go to the Times Service Center to replace it with a new one.

4.2 Maintenance

If the liquid crystal display flickers during operation, it indicates that the voltage of the battery is lower than the working voltage, and it should be turned off and charged at this time.

If there is no display on the LCD after opening the face, please shut down immediately and send it to the Time Repair Service Center.

If the user finds other abnormal conditions, please contact the Times Maintenance Service Center.

- 1Beijing Times TH132 Integrated Richter Hardness Instrument Operation Instructions

- 2Beijing Times TH130 Integrated Richter Hardness Instrument Operation Instructions

- 3DHT-200 Leeb Hardness Tester operation manual

- 4DHT-300 Richter Hardness Instrument Operation Manual

- 5DHT-100 Leeb Hardness Tester manual instructions

- 6Evaluation of uncertainty of measurement results of Leeb Hardness Tester

- 7Hardness meter calibrating and maintenance

- 8Detailed explanation of the correct operation process of Richter Hardness instrument

- 9Preparation of Richter Hardness Meter Before Use