USA BROOKFIELD DV-E Viscometer Operation Instructions

I.1 Introduction

The Rotational Viscometer produced by American Brookfield Company is the world standard for viscosity determination. DV-E is a laboratory instrument in Brookfield Viscometer series, it can be combined with other accessories of Brookfield product series such as ultra-low viscosity adapter, small sample adapter, lifting bracket, screw adapter, Used together with a constant temperature Water Bath or heater to form a wide and comprehensive viscosity measurement system.

I.2 Principle of Viscosity Measurement

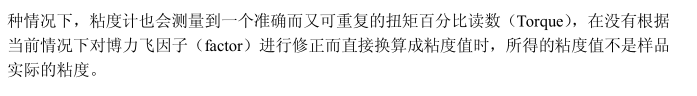

All Brookfield viscometers, including the Vibranium Flying Cone/Plate Viscometer, use a calibrated beryllium-copper alloy spring to drive a rotor to continuously rotate in the fluid, and the rotational torque sensor measures the degree of torsion of the spring That is, the torque, which is proportional to the resistance caused by the viscous drag of the rotor immersed in the sample, and the torque is thus proportional to the viscosity of the liquid.

The DV-E viscometer measures the viscosity of a wide range of liquids, and the viscosity range is related to the size and shape of the rotor and the rotational speed. Because, corresponding to a specific rotor, the actual viscosity of the fluid is inversely proportional to the rotational speed of the rotor, and the shear stress is related to the shape and size of the rotor when the torsional force generated by the rotation in the fluid is constant. For a liquid with known viscosity, the torsion angle of the spring will increase with the increase of the rotor speed and the geometric size of the rotor, so when measuring the low viscosity liquid, use the combination of large volume rotor and high speed; on the contrary, the measurement of high For viscous liquids, use a combination of small rotors and low speeds.

The DV-E viscometer adopts liquid crystal display, and the display information includes viscosity, torque, rotor number/speed.

I.4 Performance

Input voltage: 115 volts or 230 volts AC (please specify your country's voltage when ordering)

Frequency: 50/60Hz

Power consumption: less than 20 watts

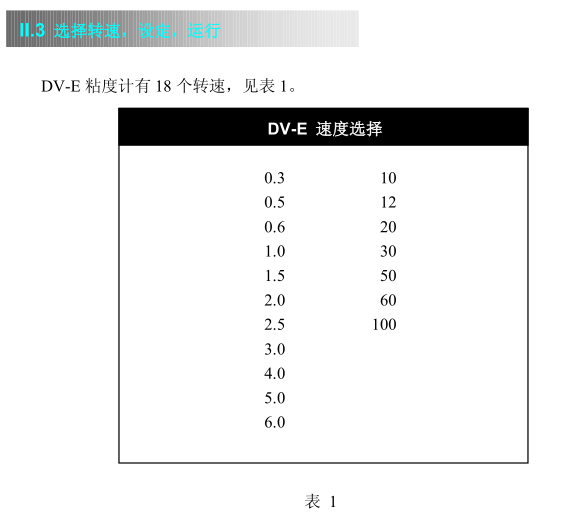

Speed: 0.3, 0.5, 0.6, 1.0, 1.5, 2.0, 2.5, 3.0, 4.0, 5.0, 6.0, 10, 12, 20, 30, 50, 60, 100 Gross weight: 9 kg

Net weight: 7.7 kg

Carton volume: 0.05m3

Carton size: 48×25×38cm

Viscosity measurement accuracy: ±1% of the range used (see Appendix D for details)

Repeatability: ±0.2% of full scale range

I.5 Installation method

1. According to Appendix E, assemble the bracket.

2. Adjust the level of the viscometer so that the level bubble is in the black circle.

3. Remove the rotor joint protection cap.

4. Turn the power switch on the back of the viscometer to the off position, and connect the power supply cable.

I.6 Control Panel Introduction

1.MOTORON button: switch motor.

2. AUTORANGE: Display the maximum value of measurable viscosity under the current rotor/speed combination.

When the power is turned on, press and hold the AUTORANGE key, and you can choose to display the viscosity in CGS (cP)

Or SI system (mPa.s).

3.SPEED/SPINDLE: Set the rotor and speed. Turn the button to the left to enter the speed selection state; turn it to the left

side, enter the state of rotor selection.

4. SELECT KNOB knob: Use this knob to select the desired speed or rotor. Rotate clockwise as speed or revolutions

The sub-number increases, and the counterclockwise rotation speed or rotor number decreases.

II.1 Automatic zero calibration

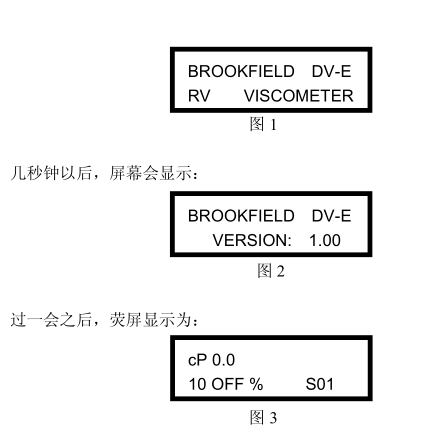

Turn on the power switch behind the main body of the viscometer. Then the information in Figure 1 appears on the display. The range of viscosity measurements is shown in the lower left corner, Figure 1 shows the RV type.

II.2 Selection of the rotor

LVDV-E viscometers are available in sets of 4 spindles and a narrow guard leg; RVDV-E viscometers are available in sets of 7 spindles and a wide guard leg; both HADV-E and HBDV-E viscometers are available in sets of 7 Set of rotors, no leg guards. (See appendix section D for more details on leggings.)

Screw the spindle onto the connection head of the viscometer, taking care that it is a left-hand helix. When connecting the rotor, pay attention to protect the connecting head of the viscometer, and gently lift it with one hand, so as to avoid strong collision and friction between the pivot needle and the jewel bearing. The nut of the rotor and the threaded joint of the viscometer should be kept smooth and clean to avoid abnormal rotation of the rotor. The rotor type can be identified by the number on the rotor nut.

DV-E needs to enter the spindle number to calculate the viscosity. The memory of DV-E Viscometer stores the numbers of all standard spindles and customized spindles, and each spindle number is two digits (appendix C has all spindle numbers).

Note: When the power is turned off, the DV-E viscometer will save the currently used spindle number and become the default spindle number when the instrument is turned on next time.

Turn the SPEED/SPINDLE switch to the right, then turn the SELECT knob until the rotor number you want to set appears, and turn the SPEED/SPINDLE key back to the middle position to confirm the rotor number immediately.

In this way, DV-E can use the new rotor number for calculation.