L535-1 Low Speed Centrifuge Instructions for Use

1. Working principle and scope of application

L535-1 low-speed centrifuge (hereinafter referred to as the machine) uses the principle of centrifugal sedimentation to separate, concentrate or purify the particles with different densities in the solution . It is widely used in fields such as blood bank, biochemistry, pharmacy, biological products, medicine, clinical testing and radioimmunity.

2. Main technical parameters:

Maximum speed 5350r/min

Maximum centrifugal force 5030×g

Maximum capacity 4×750ml

Speed control accuracy ±50r/min

Noise<70dB(A)

Power AC220V50Hz15A

Dimensions 560×660×830mm (L×W×H)

3. Structural features:

1. The machine is directly driven by a DC brushless motor. There is no spark, no toner pollution, and low noise during operation, which meets the requirements of laboratory work.

2. Due to the special vibration reduction system, the vibration reduction effect is good.

3. The machine is controlled by a microcomputer with high speed control precision. The touch panel of the instrument is convenient for the user to set the operating parameters accurately ; the operating parameters can be modified during operation, and the corresponding centrifugal force at the current speed can be viewed.

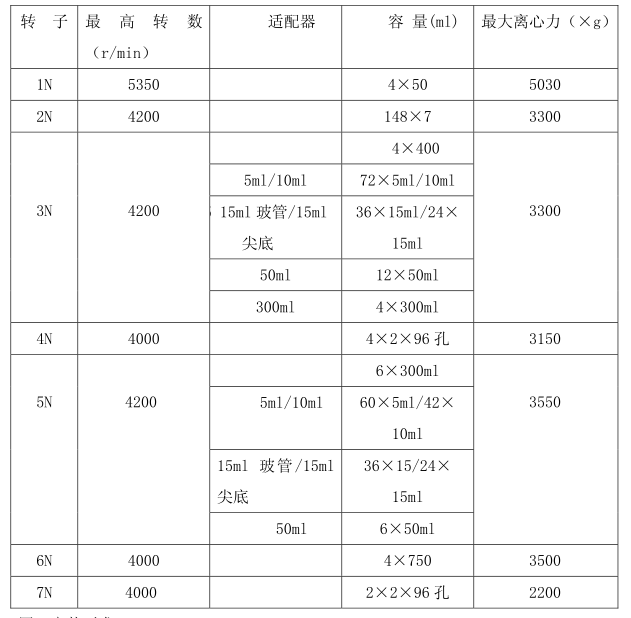

4. The machine is composed of a main engine and a rotor. The parameters of the rotor that can be used with this machine are shown in Table 1.

4. Installation requirements:

1. The instrument should be placed on a solid ground, and the minimum distance from the wall should be greater than 10cm.

2. The room should be dry and well ventilated, the relative humidity should be kept below 85%, the indoor temperature should be between 5°C and 35 °C, and there should be no corrosive substances; avoid direct sunlight on the instrument.

3. The power supply used must have a reliable ground wire to ensure the safe operation of the instrument.

5. Operation method:

1. Plug in the power socket and press the power switch.

2. Press the "STOP" key to open the door cover (use a special tool to push from the small hole on the front right side to the left when the power is not turned on ). Install the rotor and tighten the nut.

3. Place the rotor on the level meter, and adjust the two screws in front of the instrument to ensure that the instrument is level.

4. Put the centrifuge tubes that have been weighed with liquid into the rotor, and the centrifuge tubes need to be placed symmetrically in an even number; close the door cover.

5、设置转子号、转速、时间:在停止状态下时,用户可以设置转子号、转速、时间,按设置(SET)键,此时离心机处于设置状态,停止灯亮、运行灯闪烁;在运行状态下时,用户只能设置转速、时间,按设置(SET)键,此时离心机处于设置状态,运行灯亮、停止灯闪烁(停止状态下按“SET”键可以在时间、转速和转子号之间循环选择;运行状态下按“SET”键可以在时间和转速之间循环选择)。

(1)、设置转子号:按“SET”键,当显示转子号数码管右下角的小数点亮时,即进入转子号设置,再按“▲”或“▼”键选择离心机本次工作所带的转子号,共有六种转子可供选择,注意:设置的转子号要与所选用的转子一致,不可设置错误。

(2)、设置转速:按“SET”键,当显示转速最后一个数码管右下角的小数点亮时,即进入转速设置,再按“▲”或“▼”键确定离心机本次工作的转速。

(3)、设置时间:按“SET”键,当时间最后一个数码管右下角的小数点亮时,即进入时间设置,再按“▲”或“▼”键确定离心机本次工作的时间(时间最长为99分钟),时间为倒计时。

(4)、当上述三个步骤完成后,再按“认可(ENTER)”键,以确认上述所设的转子、转速、时间,然后按“START”键启动离心机。离心机开始运行,面板上显示转子号、转速及剩余离心时间。

6、离心机时间倒计时到“0”时,电机断电,5秒钟后开始刹车,离心机将自动停止。

7、在运行当中,如果要看离心力,按下“RCF”键(RCF灯亮),就显示当时转速下的离心力,4秒钟后自动返回到运行状态。

8. During centrifugation, if you need to check the original set parameters, press the SET key, the instrument will display the original set parameters; after 4 seconds (without keyboard response), the instrument will automatically return to the running state.

9. During the operation of the centrifuge, if you need to modify the operating parameters, press the SET (SET) button to the decimal point to the position of the parameter to be modified, then press the up button or down button to select the parameter to be modified, and press the OK button to confirm. Change parameters.

10. When the rotor stops (the speed is 0r/min), the door cover will be opened automatically, and the centrifuge tube will be taken out.

11. Turn off the power switch and power off the centrifuge.

6. Safety precautions:

1. When the centrifuge is running, do not move the centrifuge, and do not open the door cover.

2. After the centrifuge is moved, the level of the instrument needs to be readjusted.

3. All rotors should not exceed their maximum speed. Different rotor numbers correspond to different maximum speeds . The microcomputer program of this machine has locked the maximum speed corresponding to each type of rotor, that is, it needs to be set correctly every time the rotor number is set.

3. The normal service life of the rotor of this machine is five years, and the new rotor should be replaced when it expires. If the rotor is corroded or scratched due to improper use, the rotor should be discontinued and replaced with a new one.

4. Check the centrifuge tube for cracks before use, and do not use any cracked centrifuge tubes. If the centrifuge tube is broken during the centrifugation process, it will cause a large vibration, and it should be stopped immediately.

Seven, maintenance and maintenance:

The instrument has been designed to minimize complicated maintenance and inspection work, but daily maintenance and maintenance should be carried out as required during use to ensure long-term safe and effective work of the instrument.

1. After the centrifugation is completed, if the time interval for the next use is longer, the rotor should be taken out . Then clean and dry the rotor to avoid corrosion affecting the service life of the rotor.

2. During the centrifugation process, if the centrifuge tube is broken or other reasons, and the surface of the rotor is sticky with solution, the rotor should be cleaned and dried.

3. After the rotor is taken out, dry the rotating shaft of the motor and the matching hole at the bottom of the rotor, and apply a small amount of grease or medical Vaseline.

- 1Principle and Application of Upper Suspension Centrifuge

- 2Centrifuge Types and Precautions for use

- 3How to operate a large-capacity high-speed centrifuge correctly? [How to use]

- 4What is a centrifuge?

- 5The principle, function and use of centrifuge

- 6How to choose a centrifuge?

- 7How to test the critical pigment volume concentration of ink?

- 8What is the difference between RCF and RPM in a centrifuge?

- 9How to choose a good centrifuge?

-

CHINA ZY-LX-1 Centrifuge$ 494.00

-

-

YIHENG BLF-10K Centrifuge$ 272.00

-

YIHENG BLF-7K Centrifuge$ 236.00