Overview of film formation and post-processing of silver nanowire transparent electrode

Silver nanowires are a new generation of transparent conductive electrode materials with great application potential. This paper summarizes three main liquid-phase film-forming processes commonly used in the preparation of transparent electrodes using silver nanowires: spin coating, spray coating and rod coating, and analyzes the influence of film-forming processes on film performance and its application potential; Three types of post-processing methods including pressing and introducing medium are discussed, and the influence of different post-processing methods on the comprehensive performance of silver nanowire transparent electrodes is expounded.

Transparent electrodes are widely used in solar cells [1-3], touch screens [4-5], organic light-emitting diodes (OLEDs) [6-8] and other electronic devices. The material of the transparent conductive film layer is mostly transparent conductive metal oxide such as indium tin oxide (ITO). Under the transmittance (T) of more than 90%, the square resistance (Rs) of the material is less than 100Ω/sq[9-10], and the comprehensive performance of light transmission and conductivity is excellent. The main disadvantages of ITO film are high overall cost [11] and poor flexibility [12]. In recent years, several materials have entered people's field of vision and are expected to replace ITO, such as metal grids [13], random grids of nano-metal wires [14-15], graphene conductive films [16-18] and single-layer carbon nanotubes. Grid [19-21] et al. Among them, the silver nanowire (AgNW) random grid has greater cost advantages and application prospects.

The AgNW transparent electrode is a conductive film layer composed of a random grid of silver nanowires. The random grid of silver nanowires in the film layer is shown in Figure 1.

At present, the comprehensive performance of laboratory samples is 5Ω/sq square resistance and 92% transmittance [22], and its comprehensive performance is already better than that of ITO conductive film.

AgNW transparent electrodes also have the characteristics of lower overall cost [23] and good flexibility, bendable and foldable [24-25]. The process of preparing AgNW by liquid polyol method is relatively simple and low-cost, which is suitable for large-scale production [26-27]; the low-cost preparation technology of large-area AgNW transparent electrodes is constantly advancing [22].

The main properties of transparent electrodes are light transmission and conductivity. The light transmission performance can be characterized by the film transmittance T or the optical conductivity σOP measured by the Spectrophotometer ; the electrical conductivity can be characterized by the square resistance Rs measured by the four-point resistance test method or the calculated electrical conductivity σDC[4]. The light transmittance and conductivity properties need to be considered comprehensively. The parameter that characterizes the photoelectric comprehensive performance is ΦTE[28], which is calculated by ΦTE=T10/Rs. The ratio of conductance to light conductance σDC/σOP can also characterize the photoelectric comprehensive performance. Transparent electrodes also have performance requirements such as flexibility and environmental tolerance.

The preparation technology of AgNW transparent electrode includes AgNW ink (dispersion liquid) preparation, transparent electrode film formation and post-processing, etc. Although the size characteristics of AgNW mainly determine the light-transmitting and conductive properties of transparent electrodes prepared with it [29], the film-forming method and post-treatment also have a great impact on these properties of the electrodes. This paper mainly discusses the two process steps of transparent electrode film formation and post-treatment, reviews the characteristics of three film-forming processes and different post-treatment processes, and analyzes their influence on the performance of AgNW transparent electrodes.

1 Film formation process of AgNW transparent electrode

In order to meet the performance requirements, AgNW transparent electrodes should have high transmittance, low and uniform square resistance, and good flexibility. Therefore, the thickness of the conductive film layer should be uniform and thin (<100nm), and at the same time, be able to adhere well to the substrate. In addition, the basic requirement for the industrial production of AgNW transparent electrodes is to be able to form a large area of film, and at the same time, the film forming process has high efficiency and low cost.

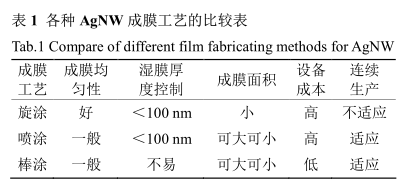

At present, most of the AgNW transparent electrode film layers are prepared on the substrate by liquid phase deposition , that is, the wet film layer (wet film) composed of AgNW random grids is deposited on the substrate by using AgNW ink or dispersion liquid, and then dried. After a series of post-processing, the film layer can meet the performance requirements. Common film-forming processes for AgNW wet films mainly include spin coating, spray coating, and rod coating. The process performance comparison of the three film-forming processes is shown in Table 1.

The spin coating method is a common method for preparing small-sized (<100mm) films by liquid phase evaporation in the laboratory. Flatten into a film. The spin-coating film-forming process is simple and easy, and can prepare extremely thin film layers. It is a commonly used film-forming method in laboratories. The unevenness of the film layer formed by spin coating comes from: 1) the solvent volatilizes during the process of spreading the coating liquid outward, and the viscosity gradually increases along the radial direction, so the thickness of the film layer increases the farther away from the rotation center; 2) the film layer along the There is a radial pattern orientation in the radial direction. Even so, spin-coating film formation on small-sized substrates still has good uniformity. However, the spin coating method is difficult to produce a uniform film layer on a large-scale substrate, and it is not easy to achieve continuous production, so it lacks industrialization potential.

The spray coating method is a film-forming method that uses the interaction between the airflow and the spray liquid, atomizes the spray liquid, and sprays the mist droplets onto the substrate. In essence, the liquid film prepared by the spraying method is composed of droplets deposited on the surface of the substrate randomly occupying space and stacking each other. The thickness is uniform, and it is generally believed that the uniformity of spray coating is not as good as that of spin coating [30]. Moreover, it is difficult for a simple spraying device to achieve the theoretical uniformity of film formation. To achieve uniform film formation over a large area requires precise control of the moving speed of the nozzle and the flow rate of the spraying liquid, resulting in high equipment costs. However, the spraying method is easy to achieve large-area film formation, and is not limited by the surface shape of the substrate, and the film formation process will not cause damage to the previous film layer. By increasing the pressure of the load gas, softening the surface tension of the spray liquid and slowing down the drying speed, spraying can prepare a thin film layer. The obvious advantage of the spraying method is that it is easy for industrialized continuous production. The electrostatic spraying method is a new spraying method, which uses an electrostatic force field to atomize and accelerate the spraying liquid, which has better film uniformity and higher material utilization, but the equipment cost is also higher [31].

The rod coating method uses a wire rod (also called a Mayer rod) as a coating tool to spread the coating liquid on the substrate. Different types of wire rods have different winding diameters, and one type corresponds to a coating thickness. The advantages of the rod coating method are: the process is simple and easy, and the film thickness can be changed by using different types of wire rods for the same solution; the solution loss rate is small (generally less than 5%); large-scale devices can be prepared and continuous production is possible. Different from spin coating and spray coating, rod coating is more suitable for coating liquid with higher viscosity [32]. The main disadvantage of the rod coating method is that the thickness of the film layer is difficult to control accurately, and the relationship between the thickness of the film layer and the diameter of the winding wire is mostly determined by experience [33]. The extruded wire rod can only prepare wet films with a thickness of more than 2 µm [34]. In addition, since the coating solution is flattened along the forward direction of the wire rod, the film layer prepared by a single coating film has orientation. Although the method of alternate vertical and horizontal coating can eliminate the orientation of the film layer [35], it is not suitable for continuous film formation. For the products, the process realization is more difficult. It is generally believed that the rod coating method is more suitable for occasions where the precision of the film thickness is not high.

In summary, the spraying film-forming process is most likely to meet the thickness and uniformity requirements of AgNW transparent electrode film formation, and is suitable for large-area film formation and continuous production at the same time. It has great application potential in the preparation of AgNW transparent electrodes.

2 Post-treatment of transparent electrode film layer and its influence on performance

After the film-forming AgNW wet film layer undergoes a subsequent drying process to volatilize the solvent, a transparent electrode film layer is obtained. As mentioned above, the conductive film layer is a random grid of silver nanowires, and the silver nanowires are in point contact, which has a large contact resistance [36], so the square resistance of the film layer is relatively high. In addition, the adhesion between the film layer and the substrate is weak, so the performance of the transparent electrode film layer is very sensitive to deformation such as bending. Therefore, the film layer also needs to go through a certain post-treatment process to reduce the square resistance of the film layer, improve the adhesion between the film layer and the substrate, and increase the connection strength of the AgNW grid, etc., to meet the requirements for the use of transparent electrodes. There are many post-treatment methods, which can be classified into three types according to the mechanism of action: heating, pressurization, and introduction of media.

2.1 Heating

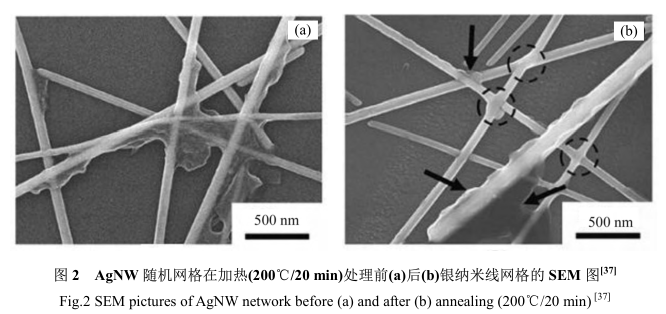

Heating is a commonly used method in the post-treatment method of silver nanowire random grid conductive film layer . The heating method is divided into overall heating and local heating. The former heats the entire transparent electrode including the substrate, while the latter realizes the surface heating of the film layer of the transparent electrode by means of radiation heating. The heat treatment method is relatively simple, and the effect of this method to improve the conductivity of the film layer is obvious. The square resistance of the film layer mainly comes from the contact resistance [24]. Before heat treatment, the contact between AgNWs in the film layer can be considered as a stacked lap joint under the action of gravity, and because AgNWs are prepared by a liquid phase method, polymer reactants (such as polyvinylpyrrolidone, PVP), so the AgNW conductive film prepared by the film-forming process has a higher square resistance. Research [37] shows that the heat treatment at 200 °C for 20 min can discharge the residual PVP at the overlapping joints of AgNWs to make them in direct contact. As shown in Figure 2), the contact resistance is reduced. After heat treatment, the square resistance of the film layer can be reduced by 2 to 3 orders of magnitude, reaching the level of 10 to 100 Ω/sq [36].

The overall heating is heat input through thermal diffusion, and the selection of heating temperature and time is mainly determined by the thermophysical parameters of PVP and the size of AgNW in the film layer. The viscous flow temperature of PVP is about 220 °C [37], so it can be removed at a temperature higher than this. However, due to the limitation of heat resistance of AgNW and substrate, the temperature of heat treatment is mostly lower than this temperature.

不同直径AgNW组成的网格,纳米尺寸效应强弱不同[38],加热处理的温度和时间也不尽相同,一般在120~220℃之间。通常AgNW越粗,耐热能力越强,膜层的加热处理温度更高,时间也更长。2012年韩国的Lee等[39]用超长银线(>500µm,直径可能超过500nm)制备的导电膜层,其加热处理工艺是220℃下保温2h。

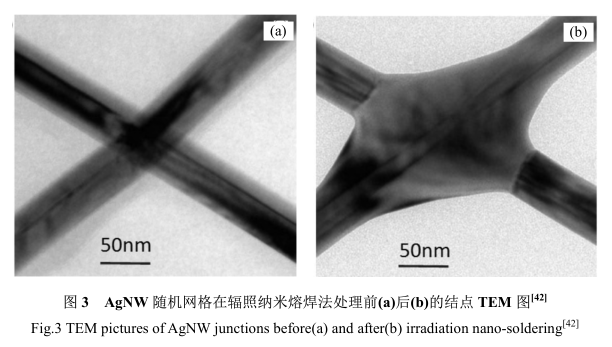

“辐照纳米熔焊”采用大功率强光短时辐照技术实现膜层中AgNW网格搭接处局部熔化而焊合,使用该技术可避免整体加热处理对柔性基材形成的破坏[40-41]。图3为采用未极化宽谱光源辐照处理[42]前后的AgNW结点TEM照片,对比图3(a)、(b)可见辐照后结点焊合。

辐照纳米熔焊的原理是通过引发AgNW表面离子共振[42-43]以及在结点处产生高强度电场使结点熔融[15]。结点处产生的热效应大大高于膜层的其他部分,可适用于不耐温的柔性基材。辐照光源可选择普通光源或激光,普通光源有设备要求低、操作简单的优点[38],激光则热效率更高且易控制输入功率[44]。总而言之,辐照的加热效率比传统的整体加热要高很多。使用大功率激光光源时,只要几秒[44]甚至几十微秒[25]就可以完成辐照纳米熔焊。Garnett等[42]还发现了辐照法的自限制效果,当结点熔焊在

一起后,热效应便会减弱至消失,这就避免了过度升温熔断AgNW。

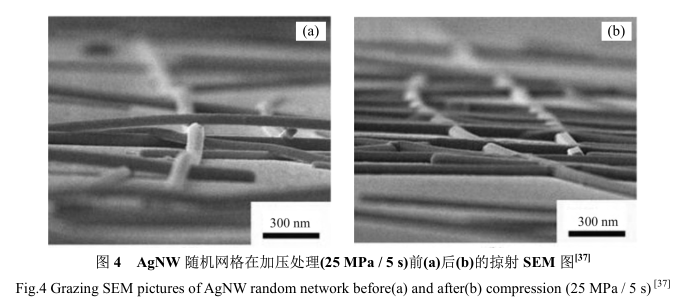

2.2加压

对成膜工艺制得的AgNW导电膜层加压处理也可起到降低方阻的效果。图4为AgNW随机网格在加压处理前后的掠射SEM图。

从图4(a)中可以看出,加压处理前,导电膜层表面并不平整,银线AgNW的搭接处因重叠两层AgNW而更厚些。在膜层表面加以几[1]到几十[37]MPa的均匀压力,搭接处厚度大因此首先受到挤压,两根搭接的AgNW被挤压变形使接触面积增大,压力足够大时AgNW甚至可以使搭接处的凸起压平而相互嵌入形成平面,进一步增加接触面积并且实现AgNW间的物理结合(图4(b)),使接触电阻显著下降。据Tokuno等[37]的研究,在AgNW导电网格上加25MPa的外压保持10s,方阻可从1.8×104Ω/sq降到8.6Ω/sq。

加压处理还可以使膜层厚度更均匀,表面粗糙度降低,改善透明电极的使用效能[37]。外压的施加除通过两片平面硬质片挤压[45]外,工业上常用辊轴滚压来实现[22]。一般来说,加压处理降低膜层方阻的效果比加热处理更明显,且工艺更容易实现。需要指出的是,AgNW之间仍然是物理接触,并没有实现晶格层面的原子接触,因此接触电阻还有进一步降低的空间。

2.3引入介质

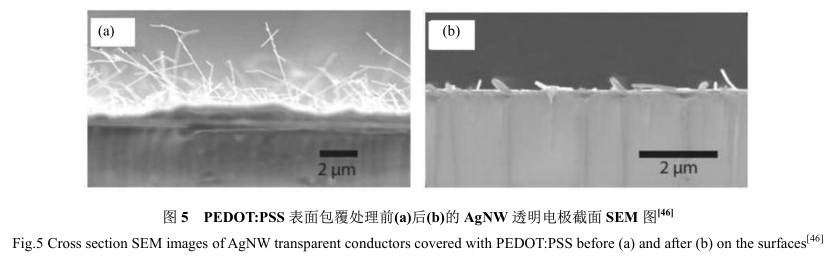

引入介质是指用物理或化学的方法在AgNW导电膜层表面引入其他物质(介质)以改善或提高透明电极的性能。按作用机理可将介质分为粘接介质、导电介质、结点熔焊介质和表面剥蚀介质。

粘接介质一般为高分子材料,存在方式是在AgNW导电膜层表面覆膜。利用高分子溶液的流动性和凝胶后树脂的粘接性在AgNW导电膜层表面成膜,大分子链上的活性官能团与基材表面形成键合,同时大分子链填充于AgNW导电网格的空隙,起粘接导电膜层与基底、保护膜层、降低膜层表面粗糙度等的作用(如图5所示)。

常用的粘结介质材料有聚3,4-乙撑二氧噻吩:聚苯乙烯磺酸盐(PEDOT:PSS)[46]、聚乙烯醇(PVA)[7]、丙烯酸树酯[45]等。表面覆膜的方法简单实用,可采用与AgNW墨水相同的涂膜方法成膜。但覆膜会降低电极的透过率,因此覆膜应尽量薄。例如,Gaynor等[46]在AgNW导电网格上涂覆一层极薄(25~100nm)的PEDOT:PSS层,制备的AgNW有较好的表面平整性和抗弯折性,但透过率只有83%,与Kim等[31]制备的未经覆膜处理的透明电极(透过率92.1%)相比,方阻相同时透光性能更差(两者使用的纳米线尺寸相近,且膜层都经过有效热退火),说明覆膜会降低透光性能。

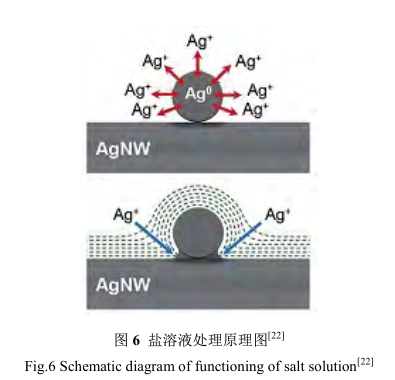

导电介质主要作为桥连物质改善AgNW搭接点的接触。Hu等[36]对AgNW导电网格沉积金的研究表明,在AgNW膜层表面镀金,可使结点电阻明显下降而AgNW本征电阻的变化不大,说明金的主要作用是填充在搭接点的间隙中增加了接触面积。但AgNW表面镀金会降低电极的透过率[47]。PEDOT:PSS也可以用于填充银线结点[24],与金相比,优点是对透光性能影响小,但导电高分子PEDOT的电导率较小,对结点电阻的降低效果不如金。例如,Ag+在含Cl-离子的盐溶液溶解和析出反应平衡以及表面能降低(如图6示意),AgNW透明电极表面的Ag溶解于盐溶液成为Ag+并优先在结点处析出Ag,使结点电阻降低[22]。简言之,盐溶液起到溶融并焊接AgNW结点的作用,该方法简单易行,只需要将成膜后的电极浸泡在盐溶液中即可。此外,Lu等[47]还提出一种光催化还原Ag+的方法,在结点沉积银,降低效果更好,同时对透光性的减弱也较明显。

结点溶焊介质主要是含Cl-的盐溶液。其原理是也起到焊接AgNW结点的作用。与前一种介质溶焊方法不同的是,Ag+的来源是含Ag+的盐溶液,而不是AgNW本身。光催化还原Ag+离子可使用普通的LED光源,因此易实现且成本低廉。Lu等用这种方法处理制得AgNW透明电极的透过率89.4%、方阻14.9Ω/sq。

表面剥蚀介质用于除去AgNW表面的氧化层。Liu等[23]发现AgNW在成膜过程中存在表面氧化,导致AgNW间接触电阻增大。他们将成膜后的电极放置在20~60℃的浓盐酸蒸气气氛中5~10min,膜层方阻显著下降。According to同样的原理,何鑫等用稀硝酸对导电膜层进行处理,膜层方阻下降95%~97%,透过率提高了3%~4%[35]。然而酸处理的实际效果并不好,方阻的绝对值仍然很大。Liu等制得的导电膜层能达到的很好的性能是透过率75%、方阻175Ω/sq,而何鑫等所得膜层很好的性能则分别为73%和45Ω/sq,与满足使用要求的综合光电性能差距仍然较大。

综合上述4种介质的作用机理可以看出,结点熔焊介质的处理工艺简单,光电综合性能改善效果明显。而其他介质处理方法中介质的加入大多以牺牲透光性能为代价提高导电性能,且大部分的实际效果差强人意。因此,在对AgNW透明电极表面进行介质处理时,应权衡利弊,综合考虑。

3结语

After more than ten years of development, the preparation technology of AgNW has become increasingly mature and has reached a high level of performance. How to use good AgNWs to prepare high-performance transparent electrodes has become a topic of concern. There are many ways to form AgNW films, among which spin coating, spray coating, and rod coating are the three commonly used methods. Spin coating has good film uniformity, but cannot form large-scale films. Spray coating and rod coating and other processes are simple and easy to achieve continuous production. In order to improve the comprehensive performance of transparent electrodes, various post-processing techniques have also emerged as the times require. Post-processing techniques can be divided into 3 categories: heating, pressurization and media action. Heat treatment is to reduce the lap resistance through atomic diffusion or welding between AgNWs. Pressure treatment also has the effect of reducing square resistance, and at the same time enhances the adhesion between the film layer and the substrate. Introducing other substances (medium) on the surface of the AgNW conductive film layer can also improve or enhance the performance of the transparent electrode. According to the different mechanism of action, the medium can be divided into bonding medium, conductive medium, node melting medium and surface erosion medium. At present, the technical method of preparing transparent electrodes in the laboratory has become increasingly mature. It is believed that through unremitting exploration, optimization of film formation process and post-processing methods, large-scale industrial production of high-quality AgNW transparent electrodes can be realized in the near future.

- 1What is film formation?

- 2Determination of specific gravity of liquid film formation substances and Pigment-containing systems

- 3Coating film formation

- 4Coating drying film formation process

- 5Coating film formation performance inspection method--paint (coating) film preparation

- 6What is fire resistance?

- 7What is the minimum film formation temperature?

- 8What is aminoalkyd paint, its characteristics and uses?