How to determine Coating percent solids experimentally?

Solid content is one of the normal quality control items in paint production, also known as the solid content of paint. Its content has a very direct impact on the quality of the formed coating film and the use value of the coating. The solid content is also called the content of non-volatile components, which refers to the ratio of the remaining mass of the coating to the mass of the sample after heating and baking under certain conditions, expressed in percentage. The higher the solid content, the thicker the film thickness when coating, which can save a lot of diluent, thus saving the cost of coating construction.

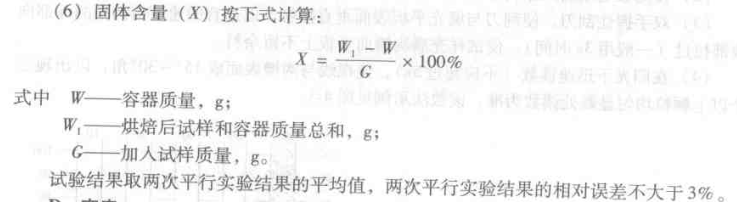

For polyester backcoat and polyester topcoat in coil coatings, the solid content index is generally controlled at (55±5)%, and the high solid polyester topcoat is (75±5)%. The commonly used method for the determination of solid content is the oven method, and the inspection method standard adopts the national standard GB1725-89. The required materials are Petri dishes, infrared lamps or ovens for drying, and balances. The measuring method is as follows: after weighing the paint, put it into the oven at a certain temperature to keep it warm, and weigh it after drying. The ratio of the mass of the residue to the mass of the sample is the solid content, expressed as a percentage.

The following points should be paid attention to when measuring:

(1) The flat-bottomed vessel for weighing needs to be constant weight first, without solvent and water.

(2) The bottom of the container where the coating is uniformly leveled and distributed should not be too much or too little. Generally, about 2g is weighed, and the sample with a lower viscosity is about 4g.

(3) The oven method can be used at a lower temperature than the infrared lamp method, and the oven method is suitable for products that are easy to decompose due to high temperature.

(4) After drying at the specified temperature, take it out, cool it at room temperature, dry it hard, and weigh it once; put it in the oven again for half an hour, and weigh it again. g), that is, constant weight.

(5) The temperature distribution in the oven is uniform, and a large number of parallel experiments can be carried out at the same time. When conditions permit, the oven is generally used for heating. In order to improve the accuracy of the determination by the oven method, crystallized hydroquinone can be added to the sample to prevent skinning and basic oxidation on the surface of the sample.

- 1MB35 halogen Moisture Analyzer: a tool for accurately measuring volatile matter

- 2What subjects are generally tested for architectural paint color paste?

- 3Ball Mill vs Basket Mill - What is the application? How are they different?

- 4What is paint solids content? How to test?

- 5What are the technical requirements for latex paint for synthetic resin emulsions?

- 6Resin percent solids

- 7Determination method of Non-volatile content

- 8How to measure the Non-volatile of Coatings?

- 9Coating percent solids assay