Raven uses RDS bar preparatory coatings in the article "Development of low temperature curing polyester coil coatings"

In the book "Coating Industry", Lei Wen from Chongqing Chemical Industry Research Institute published the article "The Development of Low Temperature Curing Polyester Coil Coating". In order to meet the new requirements of the coil coating process, a polyester with high reactivity was synthesized through experiments. Resins for topcoats to achieve desirable low temperature cure.

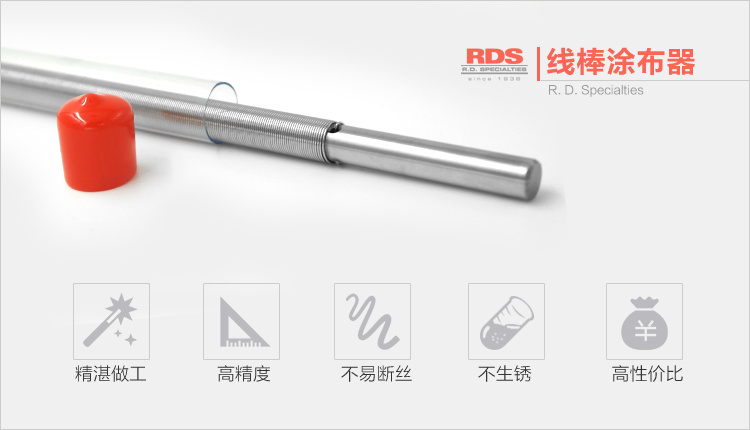

In the preparation of coil coatings, add part of polyester resin, part of solvent, titanium dioxide, carbon black, phthalocyanine blue pigment and dispersant to a sand mill for dispersion and grinding to a specific scraper fineness, and add matting in proportion Powder, and dispersed evenly to obtain a polyester topcoat. On the pre-treated galvanized steel plate, scrape the polyester amino primer with a specific type of American RDS wire rod, and after drying and curing, it is worth a specific dry film for use. The self-made polyester topcoat is scraped on, and after drying, a sea blue topcoat is obtained, and the test results of the coating film properties are finally measured.

Based on this, a lot of ideas are described in polyester synthesis, amino resin, catalyst, and pigment selection. Polyester resin; cross-linked with high imino part methyl etherified amino resin, combined with appropriate amount of isocyanate, and used self-made acid catalyst, mixed solvent and auxiliary agent to prepare a pre-coated coil coating suitable for high line speed and low temperature curing. Tested according to the standard, the coating has good weather resistance and impact resistance; it has suitable hardness and flexibility; it has good comprehensive performance and is suitable for use in the case of high line speed and low temperature curing

- 1Adhesive coating prepared by RDS wire rod film

- 2Should the coating bar be wired or formed?

- 3The smaller the RDS coating rod, why does it look more gray and black, feeling "oxidation"?

- 4Effective anti-fouling aluminum Coatings for the preparation and performance testing

- 5Optical inspection of ultraviolet curing coatings for PET film - Lv Jianbo

- 6American RDS Mayer Rods Model Daquan [Selection Guide]