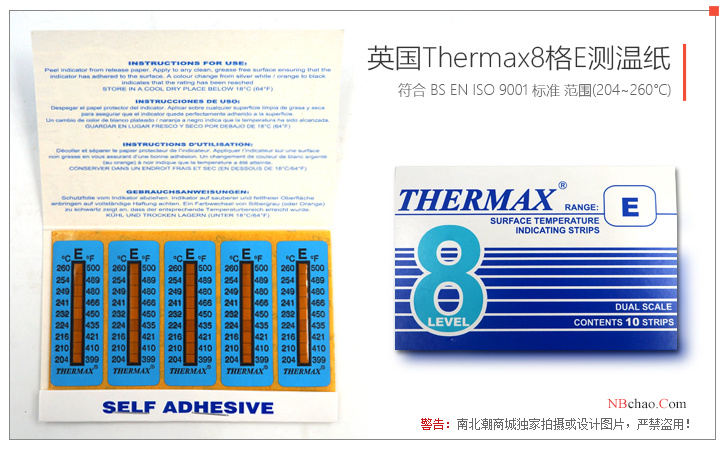

Application of Thermax temperature measurement sticker in power industry

Temperature measuring paper is used to be called color-changing temperature measuring patch in CHINA, and the name abroad is generally called "Temperature Indicating Recorder Labels", namely: "Temperature Indicating Recorder Labels". It can be attached to the device under test, and the color changes with the temperature of the device, and thus the temperature change of the device can be grasped. It has many advantages that other temperature measurement products do not have, and has attracted the attention of the industrial temperature measurement industry. At present, it has been widely used in many areas in CHINA, but in the actual application on site, some users do not know enough about the performance of the product, and there are still some misunderstandings in some aspects. Introduce to the majority of users, so that users can better grasp it.

1. What are the characteristics of temperature measuring paper (temperature recording label)?

The temperature measuring paper is easy to use and can be pasted on any flat position of the equipment. It can respond quickly after overheating, and a striking discoloration occurs within a few seconds; it records the highest peak temperature, and obvious discoloration occurs immediately after overheating , and has the over-temperature recording function that ordinary thermometers do not have (the color recording function of long-term discoloration after over-temperature) and the reversible function of repeated discoloration. Small size, obvious display, intuitive and cheap. The color change temperature error of this product does not exceed 1 degree. After overheating, the discolored color is very eye-catching. It improves the disadvantages of the outdated electric temperature measurement wax sheet: the wax sheet is not easy to stick, troublesome to use, slow in response to over-temperature, and difficult to observe.

2. How to paste and use temperature measuring paper correctly

First of all, wipe the part to be tested, and paste the test paper on the surface of the object to be tested (do not stick on the surface of water or oil).

After the test paper is pasted, the temperature will be displayed within 1 minute. The grid in the middle of the temperature measuring strip will gradually change color from bottom to top. The temperature is based on the temperature corresponding to the darkest part.

The part that has not reached the temperature or is gray can continue to be used.

The temperature measuring paper should be stored in a clean and light-proof place, so as not to deteriorate due to moisture and discoloration under high temperature

3. What is the function of the recording function? Sometimes during the inspection, it is found that the pasted temperature measuring patch has changed color, but it is immediately measured with other thermometers and found that the temperature of this part is not high, what is going on?

The product introduction mentioned that the temperature measuring paper can faithfully record the heating process of the equipment when the inspection personnel are not present, so it is called the informer of equipment failure. It can record any over-temperature process, and it is found during the inspection. If the temperature measuring patch changes color, it definitely means that the part has been overheated. The overheating process may happen now or in the past. If the temperature measuring patch is found to be discolored during the inspection, immediately use a thermometer to measure the temperature. Since ordinary thermometers do not have a recording function, they can only measure the current temperature, but not the temperature during the period of overheating. The measured temperature value is not high, indicating that the temperature of this part has dropped now, but it is also the fault point.

4. Why do you sometimes see no discoloration when you put the temperature measuring paper (temperature recording label) on the teacup and pour boiling water?

The test container for the temperature measuring paper should be a can with fast heat transfer, aluminum lunch box, etc. Since the tea cup has a heat preservation function, the heat conduction of the cup wall is very poor. After pouring boiling water, the temperature inside the cup is more than 90 degrees, and the temperature of the cup wall is often Five or sixty degrees, so it may not reach the color change temperature and cannot change color. During the test, you can bake with cigarette butts, or use a low flame, but pay attention to the distance, because the temperature of the flame can reach more than 500 degrees, and if it is too close, it is easy to burn the patch.

5. How to choose the temperature point of the color-changing temperature measuring paper (temperature recording label)?

Relevant documents stipulate that the temperature of various parts of power transformation and distribution equipment should generally not exceed 70°C, and the maximum temperature of individual parts may not exceed 80°C (including conductor busbar joints, knife switches, etc.). Corrosion and contact resistance are too large, and long-term overtemperature will lead to direct damage to substation and distribution equipment and electrical equipment, resulting in major economic losses. Due to the different equipment and ambient temperature and conditions in different places, the temperature measurement standards selected in different places are not completely consistent. In addition, the location where it is pasted must be taken into account. In places exposed to strong summer sunlight, the temperature may be as high as 50 degrees or even close to 60 degrees for the time being. In short, the temperature measurement standard is generally lower in places with relatively low ambient temperature and small load, and vice versa in other places. Generally, the commonly used detection temperatures for substation equipment are 60°C, 70°C, and 80°C. In order to allow users to better choose the temperature measuring patch that suits them, there are higher or lower temperatures 65, 70, 75, 80, 85°C and 100, 120°C, etc.) and various series of different types of patches; users can choose according to their needs. Users who used temperature measuring wax sheets in the past should pay attention, because the heat conduction and reaction speed of this product are faster than wax sheets, at the same temperature, especially short-term overheating, this product will react first and change color, and the wax sheet may not have time to melt at this time and shedding; this does not mean that the temperature of this product is formulated low! Considering the habits of wax flake users, when purchasing this product, choose a temperature that is a few degrees higher than the customary temperature of wax flakes. If you used 60-degree wax sheets in the past, you can choose a 65-degree temperature measurement patch.

6. How long is the life of the temperature measuring paper (temperature recording label)?

As long as the temperature measuring paper does not exceed the temperature, it can be used for many years, especially indoors. It can be stored for 4-5 years or even longer under normal temperature conditions. Considering that the industrial site is relatively complex and the environment is relatively harsh, we stipulate that as long as the temperature measuring patch remains white and does not exceed the temperature, it can be used for 2-3 years. It is better to replace the stickers that have changed color due to overheating in time with maintenance. When saving, it should be stored in a cool and airtight place, and it is forbidden to get close to high temperature to prevent over-temperature discoloration; avoid direct scratching, scratching, smashing and other mechanical damage.

- 1The Key Role of Thermometric Paper in Screen Printing

- 2Thermometric Paper for metallic coatings

- 3Application of Thermometric Paper in Disinfecting Dishwasher

- 4The principle and application analysis of temperature test sticker

- 5Application and use of temperature measuring paper products

- 6Changlong temperature measurement paper (temperature measurement patch) full model selection table

- 7British thermax irreversible temperature measurement paper model Daquan

- 8How much do you know about these temperature measurement sticker brands on the market?

- 9Difference Between Thermometric Paper and Thermometric Wax Sheet