On-site inspection Leeb Hardness Tester test error influencing factors

Feng Zuoming, Peng Chaohua , Lan Zhongxiang , Wang Pengwei , Peng Jun , and Wu Jinyu from the Sichuan Provincial Special Equipment Inspection and Research Institute conducted a comprehensive inspection of the equipment in the natural gas purification plant. The error influencing factors of the Hardness Tester have been researched and analyzed. In the paper "On-site Inspection of Leeb Hardness Tester Error Influencing Factors", the test principle of the Leeb Hardness Tester and several factors that may affect the error are analyzed: Analyzing the hardness Measure the impact direction, the surface cleanliness, roughness and thickness of the inspected workpiece, and propose corresponding preventive measures.

The conclusions show that: 1) The impact orientation of the Leeb Hardness Tester should choose the standard orientation specified by the Hardness Tester.

2) The smaller the surface roughness of the workpiece to be tested, the larger the Hardness Tester; the larger the surface roughness, the smaller the hardness value. The standard requirements are as follows:

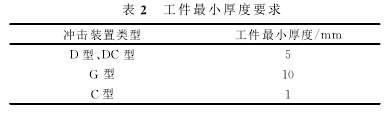

3) The thickness of the workpiece is also a factor affecting the test error of the Hardness Tester. The minimum thickness requirements are as follows:

For the detailed analysis process of the influencing factors of the Leeb Hardness Tester error, you can read the original text of "On-site Inspection of the Influencing Factors of the Leeb Hardness Tester Error".

- 1Read the Leeb Hardness Tester in one article

- 2Leeb Hardness Tester different hardness system difference

- 3What products is the Leeb Hardness Tester with D probe suitable for measuring?

- 4Factors Affecting the Accuracy of Leeb Hardness Tester Testing

- 5Leeb Hardness Tester measurement requirements

- 6Factors Affecting the Test Accuracy of Leeb Hardness Tester

- 7What are the measurement requirements for a Leeb Hardness Tester?

- 8What factors affect the test accuracy, error and repeatability of the Leeb Hardness Tester?

- 9What is hardness testing? What types are there?

-

-

PRLH150 Leeb Hardness Tester$ 259.00

-

-

-

-