Pottery and porcelain inks can be dispersed to less than 1μm basket sand mill

Industry: Ceramic Industry

Product: Low viscosity ceramic ink (100-200mPa.s), application in decoration design

Challenge: Prove that a basket mill can grind and disperse ceramic pigments finely enough.

Our goal is to achieve a D99.5 value below 1µm. Breaking up the agglomerates is critical because ceramic inks are applied via inkjet technology, and any particle larger than this size will clog the nozzle.

Our solution:

1. "Use "Dispermat CN20F2" disperser to stir and mix

Due to the low viscosity of the product, the dispersing disc cannot fully express its performance in this product. The linear velocity of the dispersing disc is also relatively slow, being 12m/s. Unable to express disintegration

Good dispersing effect of agglomerates of materials, because ceramic pigments require stronger tension. With that in mind, we're going to do a fine grind.

2. Fine grinding with a basket sander "TML 5 "

Basket Mill TML5 can be filled with grinding beads of different sizes, the filling volume is constant at 80%, and the line speed is variable. Due to the large amount of grinding beads in the basket sand mill,

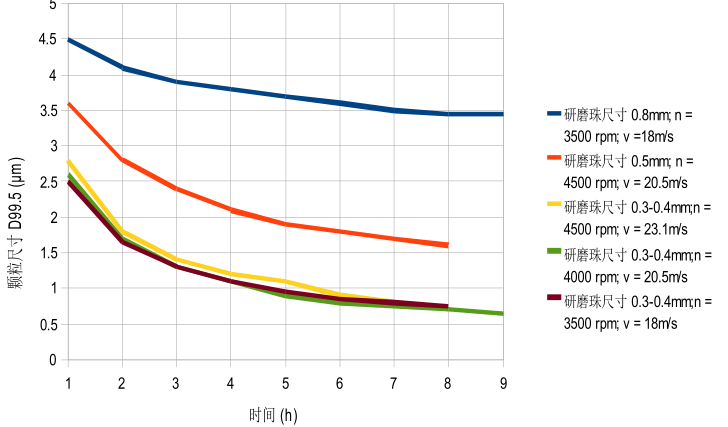

The linear speed of the grinding disc needs to be higher than normal to achieve better circulation of the product in the grinding basket, the results are shown in the following chart.

Conclusion

Smallest bead sizes (0.3-0.4mm) give better results

The lowest line speed (18m/s) grinds just as well as the highest line speed (23/s).

We know from experience that higher line speeds lead to higher wear.

equipment:

Disperser Dispermat CN20F2

Basket sanding system TML5 (SiSiC-version plus micro-device)

5 liter double-walled sample cup: holds 3.5 liters of sample

Grinding beads: Yttrium stabilized zirconia