Wear behavior of polyurea coating under two different friction conditions

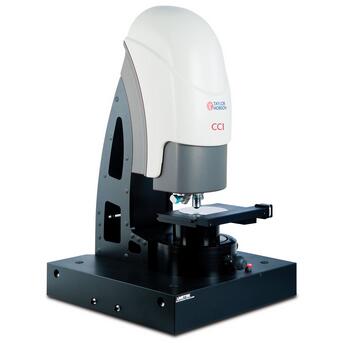

The author of "Discussion on the Wear Behavior of Polyurea Coatings under Two Different Friction Conditions" discussed the wear behavior of polyurea coatings under dry friction conditions and high-speed water-containing sand flow erosion conditions through experiments and analysis, in order to provide new materials. The application in hydraulic building drainage structure provides theoretical and experimental basis. The wear performance of the polyurea coating was tested with a Taber wear Tester and a high-speed sandy water jet erosion wear Tester. The wear surface morphology of the coating was observed with a scanning electron microscope and a white light confocal three-dimensional profiler. Surface infrared spectroscopy The component changes of the coating surface before and after the test were analyzed with electron microscopy and energy spectrum element analysis, and the wear of the coating under two friction conditions was analyzed.

Analysis conclusions: (1) As the carbon content increases, the friction and wear properties of several composite materials change. Among them, the 10% hard carbon/PTFE composite has better wear resistance, while the graphite-filled composite has poorer wear resistance. As the carbon content increases, the friction coefficient of graphite/PTFE does not change much, and the friction coefficients of carbon fiber, hard carbon, and soft carbon filled PTFE composites all increase.

(2) The wear mechanism of graphite/PTFE and soft carbon/PTFE composites is mainly adhesive wear, while the wear mechanism of hard carbon/PTFE and carbon fiber/PTFE composites is adhesive wear and abrasive wear.