How to make lab Disperser the most efficient?

Abstract: The high-speed disperser is a chemical equipment that stirs, disperses, dissolves and emulsifies coating materials and slurries. With its wide application and increasing market demand, the types and models of dispersing machines are gradually increasing. For different production materials and production efficiency, the machines and equipment required for production are also different. Below we will introduce to you how to choose a suitable high-speed disperser according to actual experiments or production needs, and maximize the dispersion efficiency. .

Selection principle:

1. Before choosing dispersing equipment, you should have a detailed understanding of the characteristics and requirements of the material, such as sample volume, viscosity, temperature, vacuum (to prevent air bubbles or excessive oxidation of the material), fineness, use place (considering the explosion-proof level), and material contact parts Whether there are restrictions on the material of the machine (you can choose ceramics if metal is not allowed), etc., so as to choose the most suitable dispersion equipment.

2. Clarify the effect and purpose of the equipment to be used, whether it is stirring, dispersing, grinding or emulsifying, etc.? If you want to realize the functions of pre-dispersion and grinding, even emulsification, on the same host machine in the laboratory, you can choose a switchable multi-function model.

3. Determine the operating parameters and structure of the disperser equipment to ensure that the selected equipment is reliable in quality, superior in performance, and meets actual application requirements.

German VMA-GETZMANN company is a world-renowned R&D and manufacturer of high-speed dispersing machines, focusing on the dispersion technology of coatings, paints, inks and other materials. Since its establishment in 1972, after 45 years of research and development, the name VMA-GETZMANN has become synonymous with the symbol of decentralized systems for the production of high-quality and innovative technologies. In order to achieve a good dispersion effect (doughnut effect*), VMA summed up the selection theory based on years of practical experience:

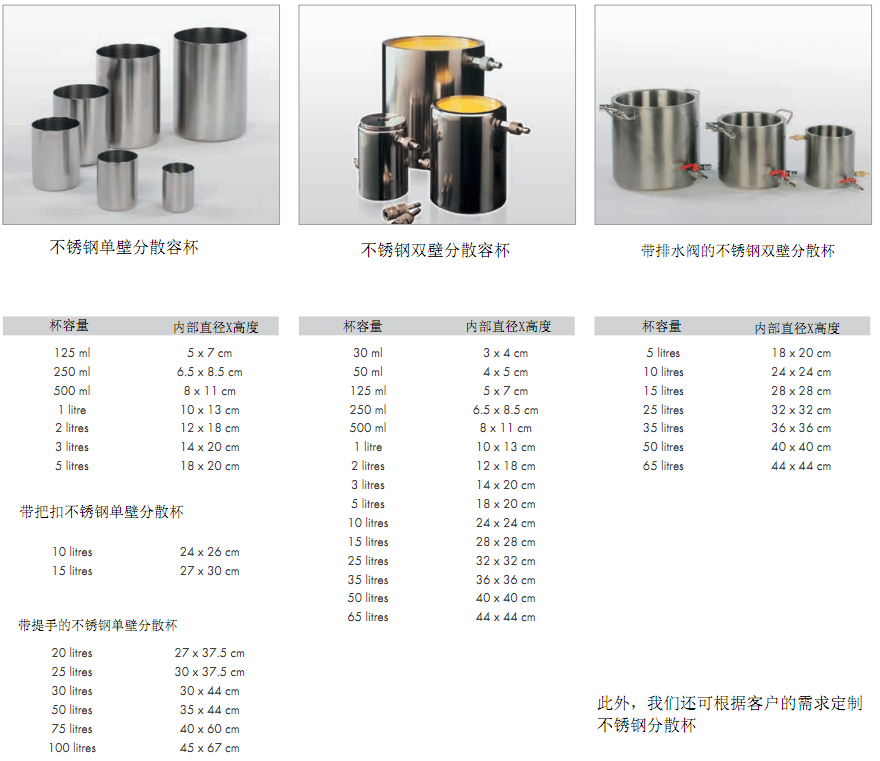

1. According to the sample volume, select a suitable sample tank . Figure 1 shows the type of sample tank. The selection principle: the filling volume of the sample is 50%-80% of the sample tank;

Figure 1: Single-wall and double-wall sample tanks

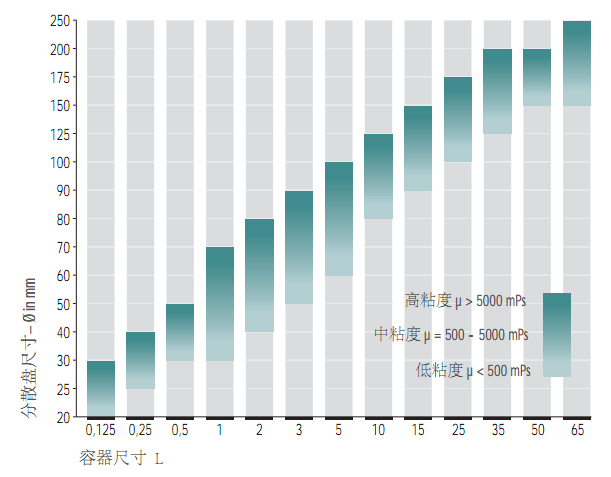

2. According to the viscosity of the sample (low/medium/high) and the size of the sample tank, select the diameter of the appropriate dispersion disc, as shown in Figure 2. For example, for low-viscosity products, the size of the tank is 10L, which corresponds to the size of the dispersion disc that should be selected 80-90mm;

Figure 2: The relationship between the viscosity of the sample and the size of the dispersion container and dispersion disc

3. Select the type of dispersion disc according to the viscosity and specific application , see Figure 3;

Figure 3: Types of Dispersed Discs

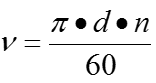

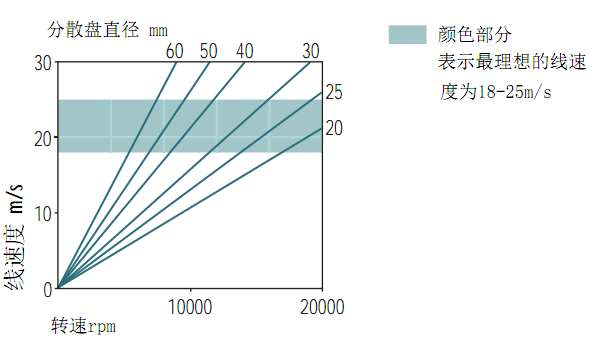

4. The most satisfactory dispersion line speed of the equipment is 18--25m/s , according to the formula

The required speed n (unit: rpm) can be calculated, and the corresponding disperser model can be selected according to the speed requirement . Where d is the diameter of the dispersion disc (unit: mm).

Figure 4: The relationship between the linear velocity and the rotating speed of the dispersing disc

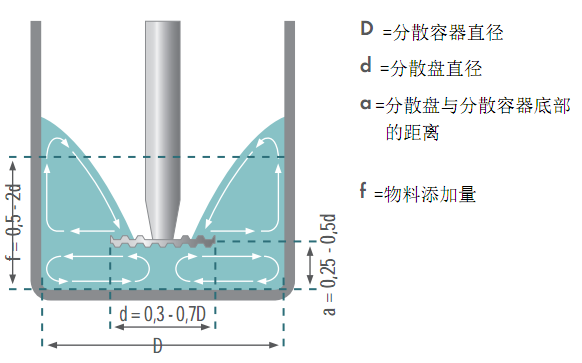

5. The distance between the dispersion plate and the bottom of the sample container

The distance between the dispersion disc and the bottom of the sample tank is between 0.25 - 0.5 times the diameter D of the dispersion disc. Allow the sample material to flow sufficiently in the sample tank so that all material can fully contact the edge of the dispersing disc and be sheared.

* Donut Effect:

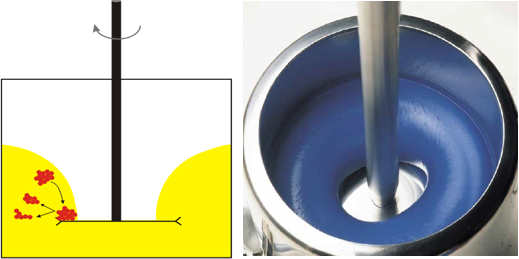

When the sample tank, the diameter of the dispersing disc, the line speed, the distance between the dispersing disc and the bottom of the dispersing container, and the rheological properties of the material are well matched, DISPERMAT will get a good dispersion result - donut effect.

After adding pigments and fillers to the resin solution, by increasing the rotational speed of the shaft, the material enters a laminar flow mode until no material adhering to the vessel wall is visible. At the right speed, a channel will form around the shaft and the dispersion disc will gradually become visible, and the material will form a donut-shaped flow pattern. The formation of the donut flow pattern means that the mechanical power input into the material has reached the maximum. In addition, because the material is stirred, all agglomerates can reach the outer edge of the dispersion plate.

- 1A Brief Discussion on the Difference between Disperser and Stirrer

- 2Several Common Coating Dispersers

- 3Inspection Contents of Chemical Plant Disperser

- 4The difference between Disperser ordinary and explosion-proof type

- 5Disperser stirring speed formula

- 6What's wrong with Disperser stirring?

- 7Main Structure of Vacuum Defoaming Disperser

- 8What oil is used in Latex paint Disperser?

- 9How to make a Disperser bucket holder?