Pigment Dispersion Equipment: Overview of Three Roller Machines

The three-roll machine, which was widely used in the paint industry to prepare pigment dispersions, is less used now.

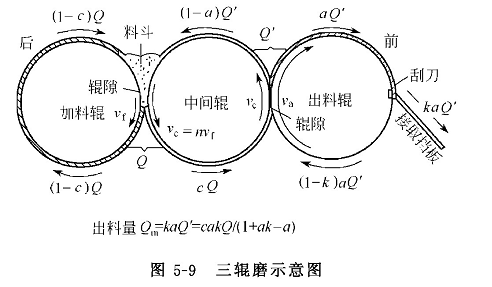

The main components of the three-roll mill are three rollers installed on the frame (see Figure 5-9). The arrangement of the three rollers can be placed horizontally, obliquely or vertically, and most of them are placed horizontally. The distance between the two rollers can be adjusted. Generally, the middle roller is fixed, and the front roller and the rear roller can move back and forth on the guide rails of the frame respectively for adjustment. The adjustment method can be manually (through the handwheel and screw), and can also be adjusted by hydraulic pressure. The three rollers rotate in opposite directions at different speeds. The front roller is a fast roller (also called a paint scraping roller), and the rear roller is a slow roller (also called a feeding roller). The speed ratio of the front roller, the middle roller and the rear roller used to be 1:2:4, and most modern ones use 1 :3:9.

The abrasive is subjected to shear between each pair of rollers to separate aggregates. The viscosity of the mill base is higher than that of other discussed methods, at 5~10 Pa·s or higher. Since the abrasive is exposed on the roll, the solvent used needs to have a low vapor pressure to minimize evaporation.

After starting the machine and adding paint slurry between the rear roller and the middle roller, as the roller rotates inward, the paint slurry is pulled to the feeding gap, and because the gap is getting smaller and smaller, most of the paint slurry cannot pass through and is forced to return It reaches the center of the top of the feeding ditch, and then is brought down by the inwardly rotating roller again, forming a continuous tumbling in the feeding ditch for a circular flow. This circulating flow in the feed trough produces relatively strong mixing and shearing. The strong shearing action occurs at the moment of passing through the feeding gap, because the gap between the feeding gap is small (about 1o~5oµm), and there is a speed difference between the two adjacent rollers. At this time, the pigment aggregates in the paste are broken and dispersed into the paint. A small part of the paint slurry passing through the feeding gap adheres to the rear roller and returns to the feeding ditch, and most of it adheres to the middle roller and enters the paint scraping gap between the middle roller and the front roller. In the paint scraping gap, because the gap is smaller and the speed difference between the front roller and the middle roller is larger, the paint paste is subjected to a stronger shearing action, and the pigment aggregates are dispersed again. A small part of the paint slurry passing through the scraping gap returns to the middle roller, most of it turns to the front roller, and finally is scraped by the scraper to the scraper holder (outlet hopper), and finally flows into the paint slurry tank. If the fineness does not meet the requirements, the operation can be repeated.

The investment and operation costs of the three-roll machine are relatively high, skilled operators are required, pre-mixing is required, and the thinning of the paint needs to be done separately. Used in solvent-free or high-viscosity dispersions containing low-volatility solvents. The three-roll machine is very convenient to use in the laboratory.

- 1Application of three-roll Grinder in homogenizing treatment of lithium-based grease

- 2Introduction and comparison of advantages and disadvantages of 4 kinds of dispersed equipment

- 3The working principle of the three-roll Grinder

- 4How to test the critical pigment volume concentration of ink?

- 5Several major operation points when the three-roll Grinder is dispersed

- 6What kind of grinding paste is the three-roll Grinder suitable for?

- 7Explanation of the dispersion process of pigments in paints

- 8An Effective Method to Disperse Pigments

- 9Coating production process