Film Gloss measurement and influencing factors

glossy concept

Gloss is the property of the surface of an object to selectively reflect light. Diffuse reflection can also be produced by a rough paint film surface. The paint film surface is uneven. When there is a certain roughness, the incident angle of the beam is not necessarily the same as the geometric angle between the beam and the surface. Light rays are reflected by specular angles on small surfaces. Because the surface is rough, there are many small faces on the surface oriented at all possible angles, causing a beam of light to reflect in all directions, which is also diffuse reflection. Diffuse surfaces have low gloss.

A good specular reflective surface is a satisfactory mirror that can correctly display the original image. The proportion of specular reflection in the total reflection (specular reflection + diffuse reflection) decreases, and the displayed image gradually becomes blurred. When it is completely diffuse, the image in the mirror cannot be seen. Therefore, the greater the percentage of diffuse reflection in the total reflection, the smaller the clarity of the image reflected by the paint film, and the smaller the distinctness of image (the clarity of the image). As surface roughness increases, specular reflection decreases and diffuse reflection increases.

Most of the reflected light on high-gloss surfaces is reflected at specular angles, while low-gloss surfaces mainly reflect at non-specular angles.

The level of gloss is not only determined by the amount of reflected light, but also depends on the contrast between the intensity of specular reflected light and the intensity of diffuse reflected light. Under the condition of the same surface smoothness and the same surface reflection effect of the paint film, compared with the white paint film, the black paint film has a better gloss, because white scatters the light entering the paint film, resulting in an increase in the degree of diffuse reflection. Although less light is reflected, there is also very little diffuse reflection. Therefore, it is impossible to prepare a white paint with the same high gloss as a high gloss black paint. The possible sheen of colored paints is between black and white. Darker colors may have a higher sheen. Gloss affects color and, in turn, color affects gloss.

Gloss is also affected by the distance between the viewer and the object. When the observer is next to the paint film, he can distinguish the unevenness of the paint film surface with his eyesight, and can judge that the surface is a rough high-gloss surface. An observer far enough away from the same surface to be unable to discern surface irregularities by vision will judge the surface to be a smooth low-gloss surface.

Observing from different angles, the color and luster of objects may change. An instrument that measures the optical properties of a sample at a continuous angle is called a variable-angle Spectrophotometer . Instruments that measure at only a few angles are called multi-angle Spectrophotometer s. Gloss is measured by recording the luminance factor as a function of viewing angle.

Gloss measurement

Gloss is generally not measured and evaluated with the naked eye. The gloss of the paint film varies widely, and everyone will rate the same; where the difference is small, the ratings are often inconsistent. The same observer cannot consistently rate the gloss of a series of samples if the gloss difference is small.

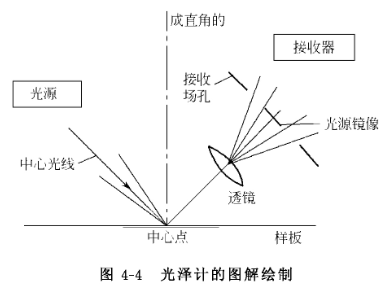

A satisfactory goniophotometer requires the incident beam diameter to be close to zero. However, the beam diameter of the actual instrument cannot be close to zero, because it needs to have enough light intensity for reflection, so that the reflected light at all angles can give a measurable response (signal) on the general-purpose photoDetector. Some practical instruments are relatively insensitive to such differences. Furthermore, the gap opened in the Glossmeter is about 2°, while the resolution limit of the human eye is about 0.0005°. Therefore, when the observer is close to the object, the Glossmeter is less sensitive to the clarity of the image than the eye. In the Glossmeter, the distance between the template and the gap is fixed, while a person observing a template can be at any distance. The widely used Glossmeter, also called reflectometer, is a simplified goniophotometer. The incident angle and observation angle are 20°, 60°, and 85°, which are commonly used measurement angles in the coating industry. Figure 4-4 is a sketch of a gloss meter.

The first step in using a Glossmeter is to calibrate the instrument with two standard plates, one high gloss and one low gloss.

A well-calibrated standard using the selected angle is required. When the instrument is calibrated with the first plate, and the second standard plate does not give a standard reading, the possible cause is that one or both of the standard plates are dirty or scratched, or the plate is out of alignment, and the light source has gone bad. Or the photometer is out of order. Both black and white standard plates are available. White standard boards are used for light colors and black standard boards are used for dark colors. White and black standard boards, even if the surface roughness is equal, have different reflections (gloss) when mirrored. Therefore, it is not feasible to have standard boards for all different colors.

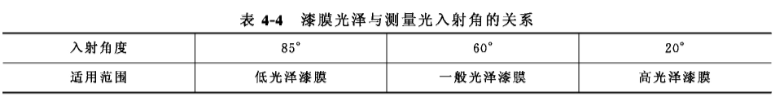

During normal operation, first measure the gloss at 60°. If the reading exceeds 70, a reading of 20° should be taken. Because the 20° reading is closer to the midpoint of the gloss meter reading than the 60° reading, the accuracy is higher. Low gloss panels are typically measured at 60° and 85°. The 85° reading may be related to the grazing gloss. The angle at which the measurement was taken needs to be reported. Multiple measurements should be taken and the data should be statistically analyzed to reduce the influence of local unevenness on the paint film surface or dirt particles on the gloss meter readings. Slight brush marks do not affect the reading if the direction of the brush marks is parallel to the plane of the incident angle. When comparing results between two laboratories, it is necessary to check the consistency of the two instruments. Measure the standard plate on each instrument, make at least three white and three black standard plates, the reading error should be controlled within ±3%, but in the low gloss range, even ±2% is a very high error.

In CHINA, a gloss meter is usually used to measure the relative reflectance at different angles to quantitatively express the gloss. Project parallel light onto a surface at a certain angle α, and measure the light reflected from the surface at the same angle α. The reflected light intensity measured at different angles is different, generally measured at an angle of 45° or 60°. According to the results measured by the 60° gloss meter, the gloss of the coating can be divided into the following grades: high gloss over 70%; semi-gloss or medium gloss 70%-30%; eggshell light 30%-6%; eggshell light to flat light 6%~2%; flat light below 2%.

The incident angle of light on the surface of the paint film is different, and the intensity of reflected light is also different. When measuring the paint film, the incident angle should be fixed first, as stipulated in the United States (ASTMD523), the relationship between the paint film gloss and the measured light incident angle is shown in Table 4-4.

The light source shines on a slender slit through which it hits the surface of the sample. The reflected light passes through another slit to the photoDetector. The incident angle and observation angle of the illuminator of the research instrument can be changed independently, but this kind of instrument is expensive and relatively difficult to maintain. It is only used for research, or as a standard for calibrating lower-level instruments.

Widely used is the specular gloss meter. The instrument reads significantly differently under different reflected light intensities, while observing

The current Glossmeters are mainly multi-angle Glossmeters (0°, 20°, 45°, 60°, 75°, 85°) and variable-angle Glossmeters (can be measured between 20° and 85°).

Main Factors Affecting Paint Film Gloss

1) The roughness of the paint film surface

① The role of pigments. The pigment floating on the surface in the paint film affects the smoothness of the plane, making the surface uneven. The surface roughness varies with the specific volume concentration (∠1l).

In the range of micron scale on the surface of solvent-based high-gloss coating, the dry paint film contains very little pigment, and the pigment concentration is very low.

Minimal effect on the gloss of the paint film. In a freshly applied wet paint film, the resin solution and pigment particles are free to move. As the solvent evaporates, the viscosity of the wet paint film increases and the pigment particles move slowly. However, the resin solution can continue to move with the solvent, resulting in a small amount of pigment in the surface layer, and a layer of varnish can significantly increase the gloss. If the large particles stop moving before the small particles, the flocculation particles will stop moving first, while the stable small particles can still move.

When the PvC increases, the amount of pigment in the surface layer increases and the gloss decreases. Pigment aggregates are not broken up during the dispersion process, which will reduce the gloss. The flocculated pigment system has a lower CPvC, so at the same PvC, the specific volume concentration (4) increases, which may produce low gloss.

② Poor leveling will reduce gloss. A brush-marked paint film that appears shiny on the surface but is actually wavy. Wrinkles and orange peel in the paint film will lower the gloss even further. Unevenness in the surface of the paint film may be the result of poor leveling of the paint, or it may be the result of application on a rough substrate.

③ The gloss of the paint film changes during application. Chalked surface gloss is significantly reduced. After the paint film is exposed to the outside, the volatilization of volatile components will cause the paint film to shrink, increase the surface roughness, and reduce the gloss of the paint film.

2) Molecular structure of the resin When the surface has the same smoothness, the level of gloss is related to the molecular properties of the paint film, especially the molar refractive index (R) of the film-forming substance, as shown in the following formula:

R= [(n 2 -1)M]/[(n 2 + 1)d]

In the formula, M is the molecular weight; d is the density; n is the refractive index.

The value of R reflects the structural characteristics of the molecule, the larger the R value, the higher the gloss. Generally, molecules containing unsaturated bonds have higher R values, and those with conjugated systems have higher R values.

Therefore, the gloss of alkyd resin coatings is higher than that of drying oil, the gloss of acrylate and styrene copolymer coatings (styrene-acrylic coatings) is higher than that of acrylate and vinyl acetate copolymer coatings (ethylene-propylene coatings), and unsaturated Polyester coatings have a high gloss.

When the pigment volume concentration is low, the oil degree of the alkyd resin is shorter and the gloss is better, and at a high pigment volume concentration, the oil degree is longer and the gloss is better. In the former case, the molar refractive index (R) of the film-forming substance itself contributes a lot to the gloss, while in the latter case, the leveling property of the paint contributes a lot to the gloss. Short oiliness means more benzene rings, and long oiliness means The paint has good fluidity.

As the refractive index of the base material increases, the gloss of the paint film also increases, but the difference in refractive index between different base materials is very small. Compared with the influence of surface roughness, the influence of the refractive index of the base material is very small. The refractive index of metal is very high, and the paint film of metallic glitter paint is usually high gloss. In order to obtain a high-gloss paint film, a polymer with a higher refractive index should be selected as the film-forming material, and the compatibility of various components in the paint formulation should be good. During the film-forming process, there should be no polymer precipitation, and the paint should have a good For leveling, the pigment volume concentration of the paint cannot be high. In order to make the pigments form a gradient distribution in the paint film, the pigments in the surface layer should be less, the pigment particles should not be too fine, and the density should not be too small.

- 1The Importance and Method of Gloss Measurement of Paint Film

- 2How to measure Gloss, use and measurement criteria for Gloss accounting

- 3Gloss measurement angle problem

- 4Coating film formation performance inspection method - film Color and Gloss

- 5Gloss measurement of surface

- 6Summary of film fog detection

- 7Gloss measurement of films with a Tester

- 8Determination of film Gloss by HNNJIK Instrument

- 9Determination of Film Gloss (glossiness)