Desktop Colorimeter for powdered iron oxidation color difference control skills

Iron oxide, alias ferric oxide, chemical formula Fe₂O₃, soluble in hydrochloric acid, is reddish-brown powder, is the main component of rust. Iron oxide is widely used. Its reddish-brown powder is a low-grade pigment. It is called iron oxide red in industry. It is used for coloring paint, rubber, plastic, construction, etc. It is an inorganic pigment and is used as an antirust pigment in the coating industry. Used as coloring agent for rubber, artificial marble, ground terrazzo, coloring agent and filler for plastic, asbestos, artificial leather, leather polishing paste, etc., polishing agent for precision instruments, optical glass, and raw materials for manufacturing ferrite components of magnetic materials, etc. .

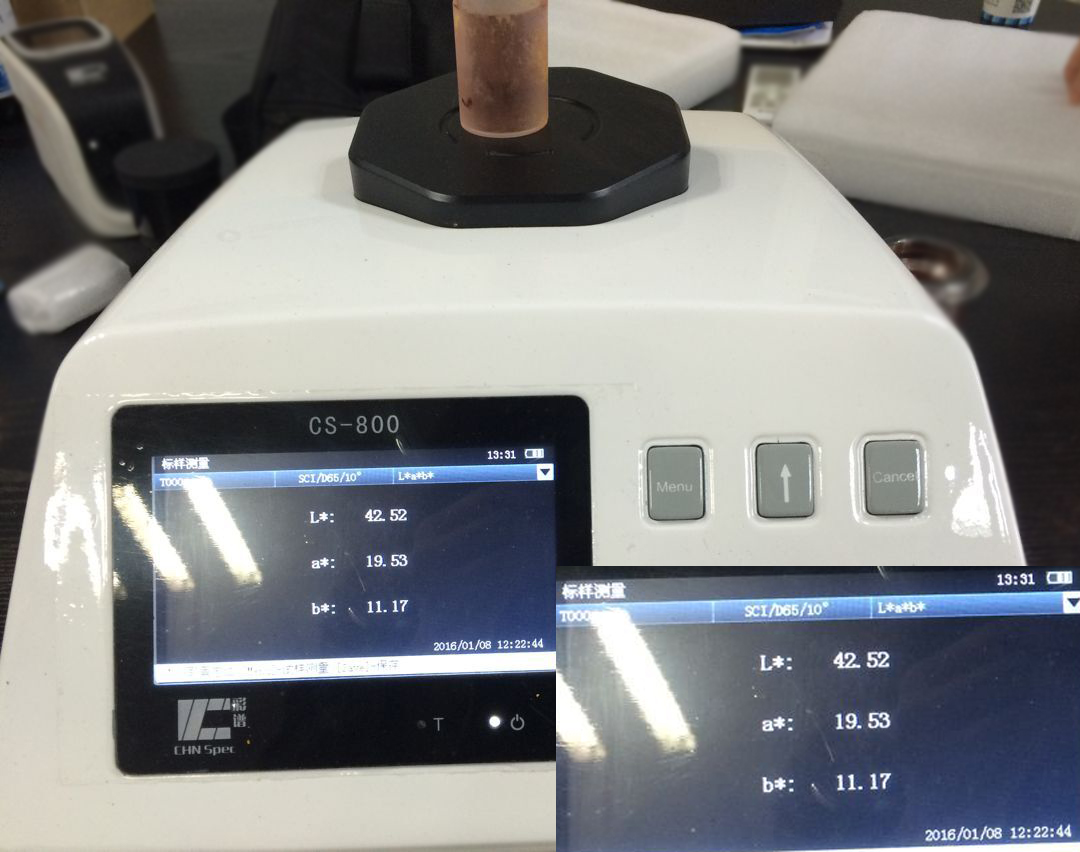

However, iron oxide, which has such a wide range of applications, also has the trouble of color difference, not only the color difference between batches, but also the color difference with other companies. Iron oxide is usually in powder form. If you want to choose an instrument with accurate measurement, good stability, and high cost performance, then you need the desktop Spectrophotometer CS-800 of Caipu Technology.

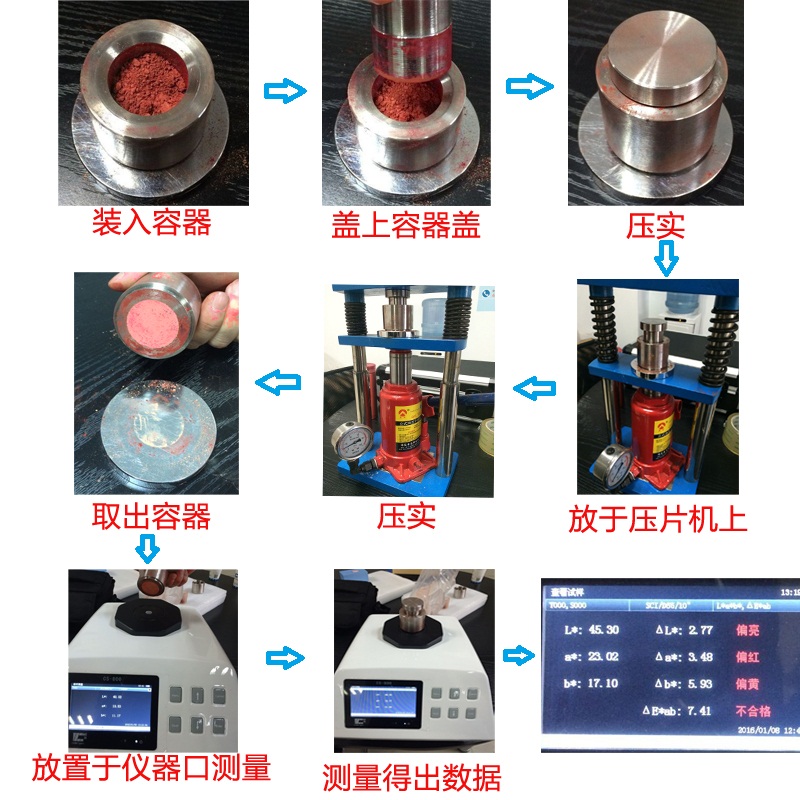

There are skills in using a desktop Spectrophotometer to measure powder samples. Let's analyze it step by step.

Prepare the iron oxide sample to be tested before measurement

(1) The first method is to put the sample into the cuvette with a medicine spoon and put it evenly to avoid gaps affecting the measurement results, and then measure the cuvette on the CS-800 test port.

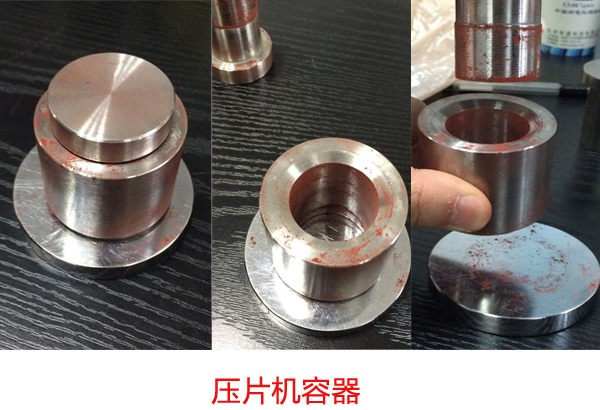

(2) The second method is to measure the sample after compacting it with a tablet press.

get the final data

- 1Desktop Colorimeter for Quality Control of Iron Oxidation Slurry

- 2Application of Desktop Colorimeter in Juice Color Measurement