Practical application of Spectrophotometer on painted metal parts

Painted metal parts are important parts and play a very important role in products in various industries. In the process of metal painting, due to materials, equipment tools, environment and other reasons, painted metal parts (as shown in the figure) 1) Finished products will produce color difference. For enterprises with high requirements, it is necessary to abandon the previous method of visually identifying color difference and seek accurate measurement methods to monitor the quality of painted metal parts.

Figure 1 - Painted Metal Parts

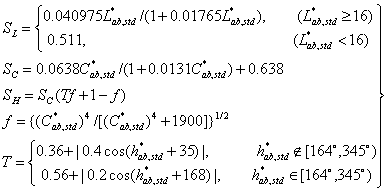

A company is a manufacturer of painted metal parts. It needs to accurately measure the color difference of the finished product to ensure the quality of the product. Therefore, it seeks to use the Spectrophotometer CS-580 of Hangzhou Caipu Technology (as shown in Figure 2) to test the painted metal pieces.

Figure 2 - Hangzhou Caipu Technology Spectrophotometer CS-580

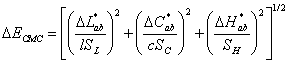

Due to the particularity of painted metal parts, using the CIELAB color difference formula widely used in the general industry as the color difference evaluation standard lacks certain accuracy. Therefore, we recommend using the color difference formula to evaluate the color difference of  painted metal parts.

painted metal parts.

The color difference formula was proposed in 1984 by FJJClark, R. McDonald and B. Rigg on the basis of modifying the JPC79 formula. Big defects, and further introduced lightness weight factor

The color difference formula was proposed in 1984 by FJJClark, R. McDonald and B. Rigg on the basis of modifying the JPC79 formula. Big defects, and further introduced lightness weight factor  and chroma weight factor

and chroma weight factor  to meet the needs of different applications. This formula is recommended by the Color Measurement Committee (CMC, Color Measurement Committee) of the British Society of Dyers and Colourists (SDC, the Society of Dyers and Colourists), and its color difference expression is

to meet the needs of different applications. This formula is recommended by the Color Measurement Committee (CMC, Color Measurement Committee) of the British Society of Dyers and Colourists (SDC, the Society of Dyers and Colourists), and its color difference expression is

In the formula

in

,

,  and

and  are the chromaticity parameters of the standard color sample, these values and the

are the chromaticity parameters of the standard color sample, these values and the  ,

,  ,

,

Both are calculated by the CIELAB color difference formula; lightness weighting factor  and chroma weighting factor

and chroma weighting factor

It is used to adjust the influence of lightness and chroma on the total color difference, so different ratios should be taken in different applications. A large number of experiments have shown that when the perceptibility of color difference is parity, it is recommended to use it  . For example, the chromaticity correction of digital systems and industries such as paint or plastics generally use the CMC (1:1) formula; while evaluating the acceptability of color, It is recommended to use

. For example, the chromaticity correction of digital systems and industries such as paint or plastics generally use the CMC (1:1) formula; while evaluating the acceptability of color, It is recommended to use  , for example, the CMC (2:1) formula is mostly used in the quality control of products in the textile industry.

, for example, the CMC (2:1) formula is mostly used in the quality control of products in the textile industry.

Since the CMC color difference formula has better visual consistency than the CIELAB formula, the quality control of different color products can use the "single number tolerance" that has nothing to do with the color region of the sample, so as to measure the color of the user It brings great convenience to the instrument evaluation of color difference. Therefore, the color difference formula has been widely used since it was launched, and many countries and organizations have adopted it to replace the CIELAB formula. Therefore, this formula will be widely used by the industry as a general and credible color difference formula.

The Spectrophotometer of Hangzhou Caipu Technology is the first spectroscopic technology platform Colorimeter in CHINA. It integrates a number of technical features and extends the boundary of on-site color quality control in production. The built-in color difference formula includes CMC (1:1) Formula and CMC(2:1) formula, so it can meet the color difference measurement requirements of painted metal parts, can accurately measure the color difference of painted metal parts, and obtain the color difference data tested according to different formulas.

The following is how to use the Spectrophotometer CS-580 of Caipu Technology to test the color difference of painted metal parts.

Step 1: Turn on the instrument, set various parameters and formulas according to the instructions, and perform black and white calibration (as shown in Figure 3 and Figure 4);

Figure 3 - Black Calibration

Figure 4 - White Calibration

Step 2: After the black and white calibration is completed, press the "Print" button to position the measurement area with the image first, align the standard sample to be tested with the test hole, be careful not to leak light so as not to affect the test result, and then press the "Test" button, "Drip" After finishing the measurement, check the test results (as shown in Figure 5);

Figure 5 - Sample measurement

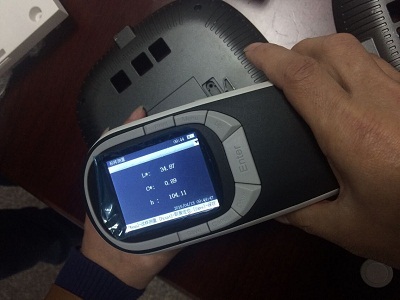

Step 3: After the above standard sample measurement is completed and saved, press the "Menu" button to enter the "Sample Measurement" interface under the standard sample, align the sample with the test hole according to the standard sample measurement method, Press the "Test" button to measure, and the color difference measurement will be completed after the "beep" sound, and the measurement result can be obtained (as shown in Figure 6).

Figure 6 - Sample measurement

- 1Colorimeter Selection Guide [NBchao Brief Version]

- 2What is the difference between tristimulus Colorimeter and Colorimeter?

- 3How does Colorimeter detect particulate matter (PM) color differences?

- 4Application of Colorimeters in paint&Coating color difference detection

- 5Several selection points about food Colorimeters

- 6Selection points of portable Spectrophotometer

- 7Non-contact Colorimeter selection considerations

- 8Color Measurement Challenges Faced by Manufacturers in the Metals Industry

- 9CS-810 Desktop Spectrophotometer Application Case Cleaner Color Detection

-

-

-

CHINA LS176 Colorimeter Colorimeter$ 627.00

-

-

CHNSPEC CRX-51 Non-Contact Colorimeter$ 11159.00

-