Characteristics and Development of Ultrapure Water Preparation Process in Semiconductor Industry

In the semiconductor manufacturing process, more than 50% of the processes are treated with silicon wafers and ultrapure water, and more than 80% of the processes require chemical treatment, which is related to ultrapure water. Therefore, the preparation of high-quality ultrapure water has become an important prerequisite technology for the development of large-scale integrated circuits. Zhang Lin's "Characteristics and Development of Ultrapure Water Preparation Process in Semiconductor Industry" introduced the characteristics of ultrapure water preparation process in semiconductor industry, the development of ultrapure water system and technology in semiconductor industry in recent years.

The ultrapure water process in the semiconductor industry has the following characteristics: 1. Large water volume and high water quality; 2. High stability of the system and strong continuity of operation; 3. Short time before putting into production; 4. The system has certain flexibility , easy to expand.

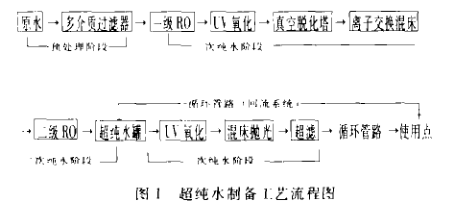

The flow chart of the ultrapure water preparation process in the semiconductor industry is as follows:

The article also introduces the development of ultra-pure water technology in the semiconductor industry, which provides a new method for the production of high-quality ultra-pure water, mainly reflected in: 1. Modularization and integration of equipment; 2. Adding a classification recovery system; 3. EDI technology; 4. Membrane contact technology.

In short , the development of ultra-pure water preparation technology is making the ultra-pure water preparation process continuously eliminate the bottleneck , providing a more stable and safe water guarantee for the semiconductor industry.