Film flexibility test

flexibility

When the paint film is bent by external force, the comprehensive performance of elasticity, plasticity and adhesion is called flexibility. The flexibility of the coating film is determined by the composition of the coating, which also includes the interface between the coating film and the substrate.

The bending test of the paint film is a test of the stretching and stretching of the paint film to the substrate adhesion. Before the test, the sample should be placed at the specified temperature for a period of time to allow it to reach an equilibrium state (temperature and relaxation) and bend at a specified speed. ASTM D1737 stipulates that it should be placed under constant temperature and humidity for 1h, and bent at a speed of 1s, otherwise, the test data reproducibility is not good.

Thick paint films tend to crack more easily than thin paint films. The edge of the bending part of the sample should be observed with a magnifying glass, and should be observed again the next day, sometimes the cracking is late.

At present, there are mainly the following five instruments for the measurement of coating flexibility.

①Spindle Tester

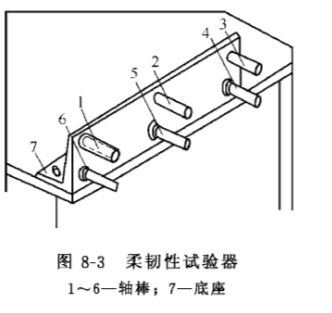

The national standard GB1731-79 "Determination of flexibility of paint film" stipulates the use of a shaft rod Tester (see Figure 8-3). It is composed of 6 steel shaft rods with different thicknesses, fixed on the base 7, and the base can be fixed on the side of the test bench with screws. The length of each shaft rod is 35mm,

1.5mm, 2mm, 2.5mm, 5mm and 7.5mm. During the test, the painted tinplate plate is bent on shafts of different diameters, and the minimum shaft diameter (mm) that does not cause damage to the paint film after bending is expressed.

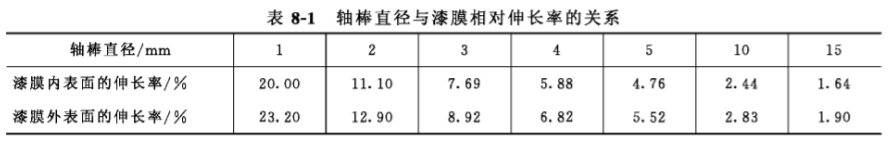

When the paint film is bent on mandrels of different diameters, the relationship between the diameter of the mandrel and the relative elongation of the paint film is shown in Table 8-1.

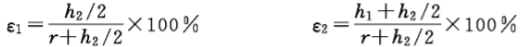

The above elongation is calculated under the condition that the thickness of the tinplate plate is 0.25mm and the thickness of the paint film is 0.02mm (20µm). The calculation formula is as follows:

In the formula, s is the elongation of the inner surface of the paint film, %; s2 is the elongation of the outer surface of the paint film, %; h is the thickness of the paint film, mm; h2 is the thickness of the bottom plate, mm; r is the shaft rod Radius, mm.

When other conditions are the same, if the thickness of the paint film (or the thickness of the bottom plate) is increased, the relative elongation of the paint film will also increase accordingly.

② Cylindrical shaft bending Tester

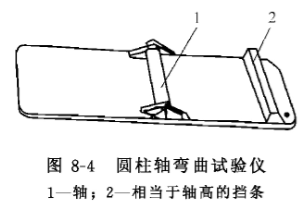

The national standard GB6742-86 "Paint film bending test (cylindrical shaft)" specifies the use of cylindrical shaft bending test (as shown in Figure 8-4). It is suitable for test panels with a thickness of less than 0.3mm, and the diameters of the shafts are 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 16mm, 20mm, 25mm and 32mm. During the test, insert the test panel with the painted surface facing outwards, close the instrument smoothly, bend the test panel 18° on the axis, and then observe whether the paint film is cracked or peeled off. The advantage of this method is that the whole panel test can be used, and the palm does not touch the paint film, which eliminates the influence of the human body on the temperature rise of the test panel.

The national standard GB6742-86 "Paint film bending test (cylindrical shaft)" specifies the use of cylindrical shaft bending test (as shown in Figure 8-4). It is suitable for test panels with a thickness of less than 0.3mm, and the diameters of the shafts are 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 16mm, 20mm, 25mm and 32mm. During the test, insert the test panel with the painted surface facing outwards, close the instrument smoothly, bend the test panel 18° on the axis, and then observe whether the paint film is cracked or peeled off. The advantage of this method is that the whole panel test can be used, and the palm does not touch the paint film, which eliminates the influence of the human body on the temperature rise of the test panel.

③Conical deflection Tester

The national standard GB11185-89 "Paint Film Bending Test (Conical Shaft)" stipulates the use of a conical bending Tester. Its central axis is a cone with a length of 203mm and a diameter extending from a maximum of 38mm to a minimum of 3.2mm. After inserting and fixing the test sample, turn the upper handle to make the test plate deflect close to the surface of the cone, and observe the minimum diameter (mm) that causes paint film damage, which represents the flexibility of the paint film. The feature of this instrument is also that the whole plate test can be used, and the discontinuity of the results with a set of conventional shaft rods is avoided. When the thickness of the paint film is known, the percentage elongation of the paint film can also be obtained.

In addition, there is another standard method for the determination of putty flexibility, which is determined by a flexibility Tester. For specific methods, refer to GB1748-79 (88) "Determination of Putty Film Flexibility".

④ Cupping testing machine

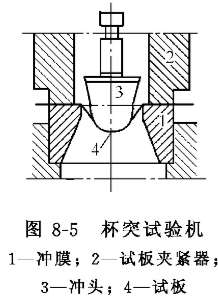

The cupping test (also called top cup test or dent test) uses a spherical punch at the head of the instrument, which is pushed to the back of the painted test panel at a constant speed to observe whether the front paint film is cracked or peeled off from the substrate. When the paint film is damaged, the minimum depth of punch indentation is the cupping index [also known as Erichsen number], expressed in mm, which is different from the performance of impact resistance. The main structure of the cupping testing machine is shown in Figure 8-5.

The cupping test (also called top cup test or dent test) uses a spherical punch at the head of the instrument, which is pushed to the back of the painted test panel at a constant speed to observe whether the front paint film is cracked or peeled off from the substrate. When the paint film is damaged, the minimum depth of punch indentation is the cupping index [also known as Erichsen number], expressed in mm, which is different from the performance of impact resistance. The main structure of the cupping testing machine is shown in Figure 8-5.

Initially, the cupping test was mainly used to determine the strength and deformation properties of sheet metal. If there is a crack in stamping, the indentation depth is the strength of the metal sheet. To test the paint film on the metal substrate is actually to measure its strength, elasticity and adhesion to the metal under the condition of elongation of the substrate. This is a required test item for those coatings that need to be post-formed in the coil coating industry and the can industry, such as coil coatings, can coatings, etc.

According to the provisions of GB9753-88 "Cupping Test of Paints and Varnishes", when testing the painted sample, the diameter of the spherical punch of the instrument is 20mm, and the test panel should be flat, without deformation, and the thickness is not less than 0.3mm and not more than 1.25mm. mm polished steel plate. In the actual measurement, if a tinplate plate with a thickness less than 0.3mm is used, when the stamping depth reaches 8mm, although the paint film is not damaged or falls off, the tinplate plate of the substrate has been cracked. The cupping test is performed under prescribed standard conditions.

⑤T-shaped bending test

T-shaped bending is widely used in coil coatings. The paint film is folded to the outside to fold the sample in half. If there is no crack at the fold, it is oT, which means that there is no metal plate on the inside of the folded metal. If the paint film is cracked, add another metal plate and then bend it. This time it is 1T without cracking, so do 2T, 3T, etc. The test is affected by temperature and turning speed, which should be strictly controlled, and should be observed after a period of time.

- 1Cracking resistance of coatings: Cupping test

- 2Two Methods and Instruments of Film Flexibility Test

- 3Cupping test and its role in Coating evaluation

- 4Key performance and specific detection methods of resilience Coatings

- 5Key performance of powder coatings and their testing instruments

- 6How are architectural coatings flexibility tested?

- 7ASTM D5019 Single-layer roofing film reinforced CSM board (chlorosulfonated polyethylene (PE)) standard interpretation

- 8Analysis of Conical Mandrel Test of ASTM D522 Film

- 9Three methods for determining the flexibility of putty coatings