Appreciation of beautiful pictures of modern environment adjustable manual film

The significant difference between the adjustable Film Applicator and the wire rod or stainless steel Applicator is the first two words: adjustable. From the perspective of cost, both the wire rod and the Applicator have a single film thickness or a few film thicknesses (referring to the multi-face Applicator), but the advantages of the wire rod are high precision and ultra-thin coating. Although the stainless steel applicator can be multi-faceted, it cannot be adjusted freely after all, which will encounter big problems when it is applied to different industries. Especially in the research and development stage of the product, the sample preparation film thickness required for the development of different products in the same laboratory is different, and the cost of purchasing multiple types of Applicators is really high! Especially when choosing imported products.

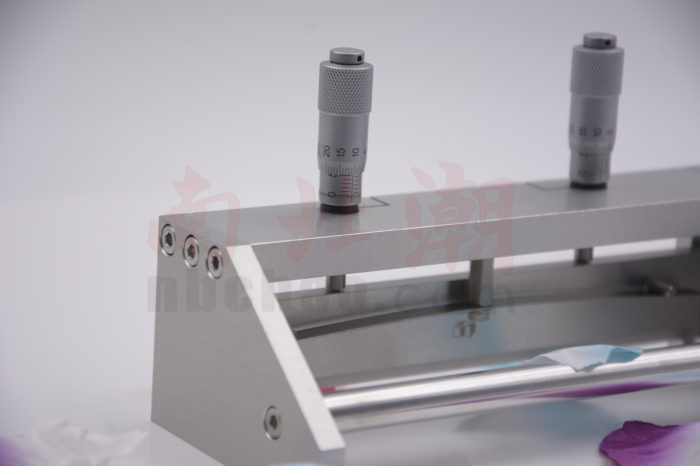

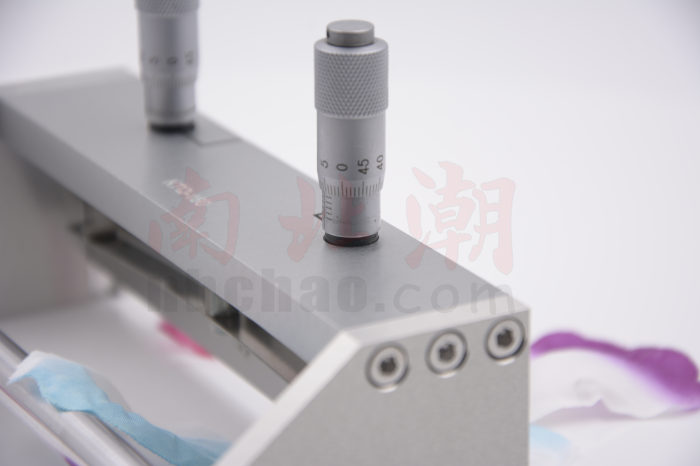

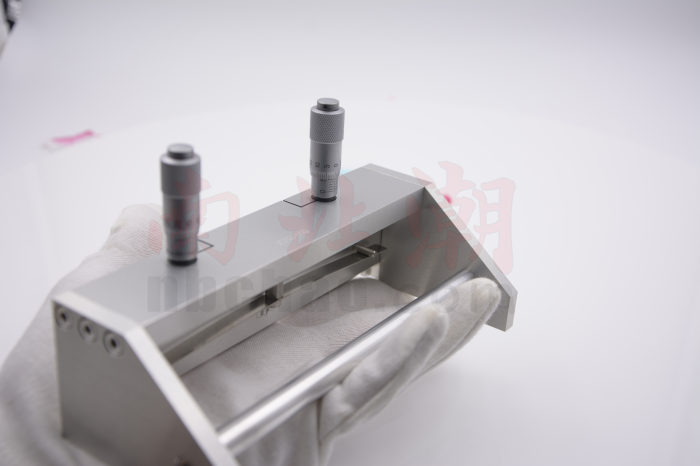

The adjustable preparer just solves this pain point. The Micrometer Applicator in the modern environment is made of stainless steel with a strong overall metal feel. There are 4 models in total, all of which can prepare wet films from 1 to 5000 microns. The difference is the thickness of the coating film, which are 50/100/150 /200mm, users can choose according to their own requirements. The accuracy is all 10μm.

The following pictures are professionally taken by NBCHAO for users to appreciate: