Cupping test of sheet metal forming limit diagram

The cupping test is one of the important test methods for determining the formability of sheet metal. The cupping value is used to measure the formability of sheet metal, which has become a standard test for determining the formability of materials. "Experimental Research on Forming Limit Diagram of Sheet Metal by Cupping Test" introduces that the author uses cupping test to measure the forming limit diagram of 20A steel plate, 5A02O aluminum plate, 1Cr18Ni9Ti stainless steel plate under certain loading conditions, and verifies the validity of the method. feasibility.

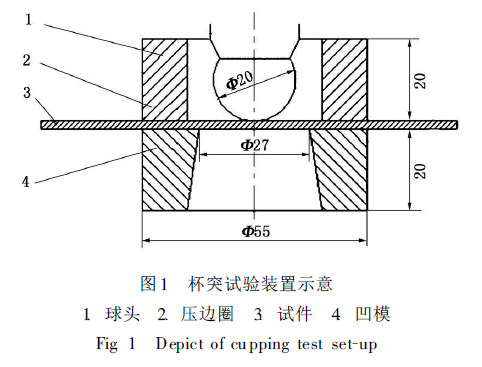

The parameters of the multifunctional testing machine used in the test are: the maximum loading force is 100 kN; the force measurement accuracy is plus or minus 5% of the indicated value; the displacement resolution is 0.001 mm; the beam speed range is 0.005 to 500 mm; the beam stroke is 1200 mm. The specific structure diagram is as follows:

Through specific experiments, the formability data of 4 kinds of plates are obtained, and the analysis of the tests is as follows:

(1) The forming limit diagram obtained by the cupping test is consistent with the forming limit diagram obtained by the bulging test, which is also in line with the predicted results of stress-strain analysis.

(2) The position of the critical area in Fig. 5 is the highest, because the sample is 20A steel with good formability, and its thickness is 2mm larger than that of several other sheets; the critical area in Fig. 6 is higher than that in Fig. 7, because although it is two kinds of plates, but the thickness of the former is 1.5mm, while that of the latter is 1mm.

(3) The lateral distribution range of the ultimate strain point obtained by the cupping test is small, and its maximum range is -0.15 to 0.28 for the 20A steel plate in Fig. 0.2; the distribution range of the longitudinal strain ε1 direction is between 0.15 and 0.2. The author believes that the reason is that the diameter of the rigid ball head in the cupping test is smaller, which leads to more severe bending deformation in the deformation zone of the sample, and it is easier to generate stress concentration, so that no larger deformation can be produced.

Conclusion: The forming limit diagram consistent with the bulging test can be obtained by using the cupping test, but the distribution range of the transverse strain data of the obtained forming limit diagram is small, and the distribution of the longitudinal strain data is relatively scattered.

- 1Cracking resistance of coatings: Cupping test

- 2Cupping test and its role in Coating evaluation

- 3Study on the Influence of Stamping Speed on Cupping Outburst

程令霞;曹阳根;杨尚磊;邓沛然;张文瑞 - 《热加工工艺》

- 4Analysis of Factors Affecting Cupping test data

郑延福;付全科;荀建民 - 《理化检验(物理分册)》

- 5Film flexibility test

郑顺兴 - 《涂料与涂装科学技术基础》

- 6What is the Cupping test?

- 7Paint and Varnish Cupping test

- 8Coating adhesion test --- Cupping test method (spherical pit test)

- 9Coating powder film Cupping test