Development and application of dynamic surface tension tintering in curtain Spreader

Whether the curtain coating method can achieve better results than other methods basically depends on the physical and chemical properties of the colorants used. Therefore, different factors such as surface tension affect the quality of color paste directly lead to some uncertain conditions, which can be called "teapot effect" or the analogy of curtains. Wetting quality also depends on surface tension. In order to achieve a certain surface tension value under specific conditions and dynamic coating, additives need to be added to the color paste. In order to define the wetting and leveling action of colorants, the measurement of dynamic surface tension introduces the main reference point in the description of colorants. Static tests such as ring or platinum plate methods cannot achieve detailed analysis of samples.

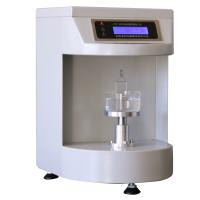

SITA's interfacial tensiometer is based on the bubble pressure method, and the test passes from a highly dynamic to a quasi-static process. In particular, SITA's t60/2 interfacial tensiometer is more suitable for laboratory applications. It starts testing with a bubble life time of 30 milliseconds. Therefore, the test of the surface tension of the color paste depending on the bubble life time is to better make the surface tension reach a specific value at a certain bubble life time, and this bubble life time is the time required by the formal customer to achieve wetting.

The SITA-based interfacial tensiometer can automatically measure the temperature, and we can better analyze samples that are greatly affected by temperature. Therefore, in order to meet customer requirements and reduce the impact risk of uncertain conditions and other influencing factors, a single quantitative evaluation for each application can be realized. In addition, a more appropriate evaluation of the test can be made by connecting the device to a computer.

- 1Water surface tension measurement based on Electronic Balance

- 2Working principle of mechanical liquid meter interfacial tensIon Meter

- 3Comparison of Liquid Surface/Interfacial Tension Testing Methods: Plate vs. Ring Method

- 4Selection guide for Surface Tensiometers

- 5Application principle and precautions of platinum ring Surface Tensiometer

- 6Coating surface tension and its effects

- 7Coating process surface tension factor

- 8Three commonly used detection methods for surface tension

- 9Ceramic ink-jet surface tension, viscosity and solutions