Application of Ultrasonic Thickness Gauge in Spinning Tube Abrasion Monitoring

1 Introduction

The wire laying machine is one of the key equipment on the production line of the high-speed wire factory. When the wire passes through the wire laying machine at high speed, the temperature reaches about 1000 ℃, and the wire laying pipe is an important part of the wire laying It directly affects the stability of the laying ring shape and the appearance quality , and in severe cases, it will cause the air-cooled line or the stacking barrel to pile up steel. At present, the service life of spinning tubes in the same industry in CHINA is generally 10,000 to 20,000 tons, and the short one is only about 6,000 tons. Nanjing Iron and Steel High Line Plant uses ultrasonic Thickness Gauges to monitor the wall thickness of the on-line spinning tube, and gradually finds out the wear pattern of the spinning tube, so that its life can reach up to 70,000 tons. Have a high degree of familiarity among peers .

2 Wear of spinning tube

2.1 Introduction of spinning shape structure tube

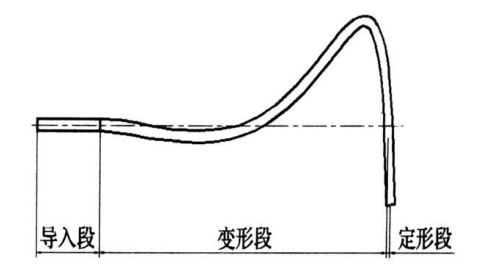

The function of the laying machine is to pass the wire through the spinneret installed on the spinneret , so that it is plastically deformed under the combined action of various forces, and the wire is transformed from a straight piece to a coil. The shape of the spinning tube is shown in Figure 1, and the spinning tube can be divided into three parts according to their functions:

Lead-in section: smoothly lead the wire into the deformed section;

Deformation section: the wire is forced to bend and ;

Shaping section: shape the coil.

2.2 Causes of wear of spinning tube

The wear of the spinning tube With the adjustment of the variety structure of our factory, the output of high- strength and alloy steel continues to increase; the rolling speed of small-size wire rods increases and the output increases; some spinning tubes are due to poor processing and forming, improper transportation, The shape curve does not meet . Abnormal wear and tear frequently occurs on the spinning tube after it is put into use . Since the wear condition of the inner wall of the laying pipe is not easy to track, before using the ultrasonic Thickness Gauge, the laying pipe is replaced mainly according to the rolling tonnage and the shape of the laying ring, which may easily affect the product quality and cause downtime . When producing products with specifications such as Υ5.5 and Υ6.5, it is easy to have unstable spinning and poor loop shape, and even cause the spinning tube to be worn out and forced to stop for replacement during the production process.

3 Ultrasonic Thickness Gauge

The principle of ultrasonic thickness measurement is similar . The ultrasonic pulse emitted by the probe reaches the object to be measured and propagates in the object. When it reaches the interface of the material, it is reflected back to the probe . The thickness of the material to be measured .

Performance:

Measuring range: 1.2~225.0mm

Measurement error: ±(1%H +0.1)mmH is the actual

Operating temperature range: 0~60℃

Accuracy: 0.1mm

4 Using ultrasonic Thickness Gauge to monitor the wear of online spinning tube wall

The wall thickness of the new spinning tube is generally about 8mm. After the online use, the replaced spinning tube is dissected in sections to observe the internal wear and tear. It is determined that the weakest area of the tube is between the 6th and 7th positioning cards. A steel blocking accident occurred after time-grinding. By using the early roll change time every day to detect the weakest area of the cooled on-line laying pipe with a Thickness Gauge , and statistically analyze the test data, it can be seen that the wear of the laying pipe will be aggravated in some specific cases.

1) The curve shape of the spinning pipe body: when the new spinning pipe curve and the assembly position of the spinning disk are quite different, especially when the curve of the deformed section does not meet the requirements, the installation is very difficult, and the spinning situation Not good, it may even cause abnormal wear on the wall of the spinning tube. During production, once a new spinning tube was put on the line and used for one shift, the spinning ring shape was abnormal. Use an ultrasonic Thickness Gauge to check that the wall thickness is only 1.5mm. Replace the spinning tube. After the wire tube passes through the cold billet, it is found that its shape curve and standard deviation are relatively large. Therefore, it is required to check . The bending curve fits well with the spinning disc installation, and the gap between the spinning tube and the spinning disc installation is less than 1.25mm. Only the spinning can be used online.

2) Curve grinding and condition inside the spinneret: According to observation, it is found that after the spinneret is replaced with a new spinneret, it is directly used for the production of small-sized wire rods of Υ5.5 and Υ6.5 ; the wall of the spinneret will appear abnormal Wear and tear, through the measurement of the wall thickness of the spinning tube by the ultrasonic Thickness Gauge, it can be known that the wear amount is 2 to 3 times that of the normal production, and the daily wear of the spinning tube wall is as high as 0.5mm. However, after the production of large-scale finished products such as Υ8 and Υ10 is replaced by small-sized finished products, the shape of the laying ring is relatively stable, and the daily wear of the pipe wall is relatively normal. It shows that the large-scale finished product has a significant correction effect . Therefore, it is required that after the spinning head is replaced with a new spinning tube, try not to go online directly for the production of small-size wire rods (specifications below Υ6.5, including Υ6.5); The above specifications (including Υ8mm specification) are run-in on-line, and can be used as the official spare disk after two days According to the actual production situation, the high-line factory requires that the two spare disks have to pass the actual production inspection and be in a ready-to-use state. The equipment department can basically keep the spare spinning reels in a hot standby state by reasonably replacing the spinning reels according to the production plan , so as to meet the production needs of various specifications and varieties.

3) Continuous rolling of the same specification: the longer the continuous rolling time of the same specification, the greater the wear on the tube wall of the spinning tube, especially for Υ5.5 and Υ6.5 small-size wire rods. It can be known from the wall thickness measurement that if the continuous rolling of the spinning tube wall, the daily wear amount will increase by 0.1 to 0.2mm compared normal conditions. Therefore, in order to prolong the life of the spinning pipe, it is required to avoid continuous rolling of the same specification for a long time in the arrangement of production specifications .

4) The influence of some special specifications and steel types on the wear of the spinning tube: when the welding wire steel of the Υ5.5 specification is produced, the tube wall is the most serious. It can be known from the measurement of the wall thickness of the spinning tube by the ultrasonic Thickness Gauge that the wear amount per day is about 0.5 mm when the above two specifications are produced. External conditions will cause abnormal wear . In view of the abnormal wear of the spinning tube caused by the high spinning temperature during thread production, the tail purge is temporarily changed from the bypass to the air normal purge after the test to reduce the spinning temperature. The temperature inside the tube, although the iron oxide scale in the spinning tube will not be easy to blow off, it can be checked regularly with professional tools to ensure the stability of the spinning ring shape.

5) The dynamic balance level of the laying head: the balance of the laying head will change after the new pipe is installed, the greater the unbalance, the more unfavorable the formation of the internal curve of the laying pipe, and it is difficult to guarantee the quality of the laying wire, and it is also It will cause abnormal wear of the spinning tube, and in severe cases, it will threaten the safety of the equipment and cause an alarm to stop. Therefore, it is necessary to use a special instrument .

As the wear of the spinning tube increases, the internal curve will change, and the spinning condition will also dynamically change with it. Only by regularly inspecting the spinning tubes, making statistics on the online production tonnage of the spinning tubes according to specifications and varieties , checking whether there are cracks on the surface of the spinning tubes every day, and using an ultrasonic Thickness Gauge to measure the wall thickness of the spinning tubes. Measure , observe and analyze its changes. Since the wear of the spinning tube is a process, it is necessary to maintain frequent observation and measurement, and it is possible to arrange for the replacement of the spinning tube before it affects production. According to the current use of the spinning tube, the equipment department believes that once the ultrasonic Thickness Gauge measures the minimum wall thickness of the spinning tube used online at about 3mm, it is necessary to arrange for replacement. If the inspection finds that the spinning tube has obvious cracks Need to arrange for spinneret replacement.

5 Conclusion

By monitoring the spinning tube with an ultrasonic Thickness Gauge, we know the amount of wear on the spinning tube with different specifications and different steel types, and increase the service life of the spinning tube by rationally arranging the production plan. The thickness of the spinning tube used online can be grasped in real time , which provides a basis for rationally arranging the replacement of the spinning tube. Judging from the current situation, the problem of unstable silk spinning of the laying machine has been basically solved. In the past six months, the unplanned replacement of the spinning tube and the disorder of spinning have dropped from more than ten hours per month to more than ten minutes per month now. At the same time, the influence on the continuous quality of the finished product is eliminated, and the high-quality ring shape is guaranteed, and the ring shape of some important steel types such as steel fiber , steel cord, and export material is greatly improved.

- 1Principle, Function, Application and Selection of Multifunctional Ultrasonic Thickness Gauge

- 2Principle, Application and Type Selection of Ultrasonic Thickness Gauge

- 3Principle, Application and Type Selection of Ultrasonic Thickness Gauge

- 4Principle, Application and Selection of Ceramic Ultrasonic Thickness Gauge

- 5The Principle, Application and Precautions of Copper Plate Ultrasonic Thickness Gauge

- 6Application, Principle Introduction and Precautions for Selection of Pipeline Thickness Gauges

- 7Principle, Characteristics and Application of FISCHER Coating Thickness Gauge

- 8Principle and Application of Ultrasonic Thickness Gauge

- 9Application of Film Thickness Gauge in automobile paint thickness measurement