Talking about car painting quality control

product design

"Quality is designed, not manufactured", which shows the importance of the design process to product quality. Therefore, in order to improve the quality , we should study the quality of the product from the product design stage. In the product design, through the research on the passability, operability, anti-corrosion and sealing performance of the body-in-white structure, the coating quality can be well improved.

1.1 Passability of BIW

The structure of the body is complex, and the structure of the body of different models is very different. This requires the confirmation of the passability of the new model on the existing painting equipment, mainly including the following aspects: the bearing capacity of the spreader and the transportation chain, and the safety of the parts. Portability, installation of painting jigs on the vehicle body, etc.

1.2 Workability of BIW

The research on the functional properties of the inner/outer panels of the body-in-white mainly includes the prediction of areas where paint flow marks or insufficient paint may occur, the division of automatic spraying and manual spraying, the evaluation , The analysis of parts that cannot be injected and the evaluation of the working convenience of the injection (wax) gun.

1.3 The corrosion resistance of the body

The research on the anticorrosion of the car body mainly includes confirming the position and size of the electrophoresis power-through hole, the pre-treatment electrophoresis drainage hole, the vent hole and the anti-corrosion wax hole, the method of preventing water accumulation on the bottom plate and the discharge time, the wax spraying position and the size of the wax spraying etc.

1.4 Body tightness

The research on the airtightness of the body mainly includes the process of spraying (injecting) the glue, the confirmation of the working space (checking interference), the water leakage the tightness of the connection parts, joints and notches of the body panels. analysis etc.

2 Selection of coating materials

2.1 Approval of new materials

Before mass supply, all paint materials need to undergo a comprehensive approval test, including raw material indicators, construction performance indicators, film-forming performance indicators, and supporting performance with other materials. The approval items of phosphating materials mainly include the performance of phosphating film and the matching of phosphating film and electrophoretic primer

performance. The approval items of electrophoretic paint mainly include the performance of the original paint, the parameters , the performance of the paint film, and the compatibility with the phosphating layer and the middle coat/top coat . The items that need to be approved for the development of intermediate coating/finish paint include: the performance of the original paint and paint construction performance, the appearance of the paint film, mechanical properties, resistance to chemical media, corrosion resistance, water resistance, aging resistance and temperature change resistance.

2.2 Batch supply acceptance

All coating materials used in production (pretreatment chemicals, paint , PVC, wax, etc.) are inspected and accepted in batches, strictly in accordance with material quality standards and production process tests, focusing on raw material indicators and construction performance indicators to ensure Unqualified materials will not be put into production.

2.3 Monitoring during material use

To better control the quality of coating, not only qualified coating materials are needed, but also effective monitoring . The production process is mainly monitored through the following methods:

⑴Monitoring of key parameters of pre-treatment and electrophoresis production lines: by testing the parameters of each bath solution twice per shift, especially the bath solutions of the two key processes of phosphating and electrophoresis , to ensure that the parameters of the bath solution are stable and within the range of process requirements Within, so as to ensure that the car body in the process of pre-treatment and electrophoresis

The properties of the paint film all meet the requirements.

⑵ Take bath solution on site, laboratory swimming plate test: take bath solution from the site once a week to test in the laboratory to ensure that the various properties of the bath solution meet the standard requirements.

⑶Production line hanging sample (pretreatment, electrophoresis, PVC), laboratory test performance: through hanging plate test on the production line, to test the performance of phosphating film and electrophoretic paint film, to ensure that each layer of paint film meets the performance requirements . Regularly go to the workshop to pick up the painted parts, and go to the laboratory to conduct performance tests to monitor the quality level of the vehicle's painting.

⑷Paint film performance test: randomly collect a certain amount of car bodies every day, at least one electrophoresis car body, intermediate-coated car body, and top coat, and test the paint film properties such as appearance, drying, film thickness, and adhesion. And measure the NAP value of the appearance level of the paint and compile the "Paint Quality Weekly Report" for analysis. Through the above tests, the main quality problems in the production process are collected, and timely analysis and rectification are made to promote the solution of coating quality problems, thereby improving the coating quality.

3 Quality control of coating production process

In order to better control the production quality of the painting workshop, the painting workshop has developed a series of quality control indicators as KPI indicators for monitoring quality, such as: straight rate of painted body, straight rate of PVC, paint AUDIT, NAP value, primer Grinding points, mid-coat grinding points, top paint grinding points, paint points deducted in the vehicle AUDIT, etc., and quantified these indicators; in order to ensure the smooth realization of the above quality indicators, the painting workshop carefully A good index guarantee system has been established in several aspects such as , environment and process monitoring.

⑴In terms of people : Quality awareness for new employees before they enter the factory

Training, so that they can form a certain quality awareness before starting work; in the process of production , through various trainings such as "master teaching apprentice", "substituting head teacher teaching month", "workshop director teaching week" and so on To enhance the quality concept of employees and make them pay more attention to the quality in hand; carry out the training of "QC activity method", "8D problem solving method", "error-proofing technology application" and other common methods in solving quality problems, so that employees can be more Master the methods of quality problem ; let employees receive training and learning from the five major quality manuals, quality system audits, special quality tools and other good quality improvement methods of the company through "going out, inviting in" and other methods.

⑵In terms of equipment : "If a worker wants to do a good job, he must first sharpen his tools." Good equipment is the premise to ensure good quality. In the production of cars, there are many equipments in the coating process. It is necessary to prepare the "Equipment Operation and Maintenance Operation Through regular equipment lubrication and maintenance, the normal operation of the equipment is guaranteed, so as to ensure the quality of the coating. .

⑶In terms of materials : most of the coating processes are exposed to chemicals, such as pre-treatment, electrophoresis, PVC, wax spraying, paint mixing and post-treatment, so the amount of chemicals added can directly affect the stability of the bath The monitoring of the amount of various chemicals added is particularly important for the control of coating quality. There are many types of chemicals for pretreatment and electrophoresis and the frequency of feeding, such as pretreatment degreasing agents, surface conditioners, phosphating additives, phosphating accelerators, electrophoretic electrophoretic colorants, electrophoretic solvents, etc., for this situation , the paint shop and the material supplier adopt the method of "one-vehicle settlement", that is , the test of all the parameters that need to be controlled and the type and quantity of materials added are completed by the chemical supplier, and the paint shop only undertakes the task of adding materials. This not only saves manpower in the painting workshop, but also can effectively control the quality of pre-treatment and electrophoresis.

During the feeding process of PVC glue, the PVC glue conveying system is an important equipment. In order to ensure that there is enough glue in the rubber barrel, it is necessary to add an alarm device to the glue conveying system. Trigger switch, PVC station installs alarm lights, and realizes automatic monitoring through the flashing

For the paint delivery and mixing system, the number of blows of the Circulating Chiller, paint delivery, return pressure and paint temperature and other parameters are used for real-time monitoring; secondly, TPM (full production maintenance) maintenance is performed on the paint delivery and mixing system to ensure the normal operation of the equipment The third is to regularly monitor the temperature and humidity, ventilation conditions and air cleanliness of the paint transfer system environment.

(4) Method : Process documents are the foundation and basis of coating operations, so to control the quality of coating, it is necessary to implement special management on process documents. The system clerk in the painting workshop is responsible for uploading , thereby ensuring the integrity of the process documents and ensuring that the operations of employees are based on evidence; they also conduct tests on various important parameters of painting every year. Confirmation of the method, so as to realize the continuous ; in order to ensure that employees implement according to the requirements of the document, the coating implements a three -level process discipline inspection method, which is the process discipline at the company level, factory level and workshop level. examine.

⑸Environmental aspects : A good painting environment is the prerequisite for obtaining a good paint film quality , so to get a good paint film, it is necessary to strictly control the "four degrees" of painting (cleanliness, illuminance, temperature, humidity) control.

①Cleanliness: First, the entry and exit of personnel in the painting workshop must be controlled, especially the entry and exit of personnel in the spray booth. Those who enter the spray booth must blow dust; secondly, the cleanliness of the spray booth, drying furnace, and clean room must be higher. Use laser particle counters to measure the cleanliness of the area; third, regularly confirm the air balance of each section of the spray booth, check whether normal and effective, and regularly replace the filter cotton according to the actual production situation; Various transportation chains, oil trays, paint spray booths, Drying Ovens and other equipment are cleaned and lubricated to ensure that they do not drop iron filings or dirt.

②Illuminance: For the illuminance of each station in the workshop, the illuminance standard shall be formulated by the craftsman, and regularly measured and monitored; the lighting system of the workshop shall be in charge of by a special person, so that the lighting damage can be repaired in time.

③Temperature and humidity: The temperature and humidity of the spray booth is one of the key parameters to ensure a good paint film. The monitoring of the room temperature and humidity of the spray paint needs to be carried out from the following aspects : Personnel regularly check the air-conditioning equipment to ensure that the temperature and humidity in winter and summer meet the production needs; in addition, it is necessary to monitor and record the temperature and humidity, and the craftsmen and coating technicians must take corresponding measures in time according to changes in temperature and humidity, such as adjusting temperature and humidity or adjusting Paint construction parameters, etc.

⑹Process monitoring

There are three ways to improve the manufacturing quality of products: pre-prevention, in-process control, and post-inspection. Pre-prevention is the prediction , which may not be detailed enough; post-event inspection, the event has already happened, and the response is slow; in-event control is an effective method to improve manufacturing quality.

The items that the paint shop has passed the process monitoring include:

①Monitoring of electrophoresis, intermediate coating, topcoat drying and adhesion: timely reflect the basic performance of each layer of paint film and the operation status of the drying furnace;

②Monitoring of film thickness of electrophoresis, intermediate coating and top paint: timely reflect whether the construction parameters and construction methods of each main process meet the requirements;

③PVC gluing monitoring: timely reflect the quality of gluing and whether the thickness of glue sprayed meets the requirements;

④ Monitoring of electrophoresis, intermediate coating, and topcoat grinding points: timely reflect whether the environment of the coating workshop and the coating status are qualified.

4 Communication of quality information

Effective communication and transfer of quality issues is the prerequisite . In order to ensure that the relevant responsible units or persons can obtain and understand the quality information in a timely manner, the painting workshop adopts the following methods.

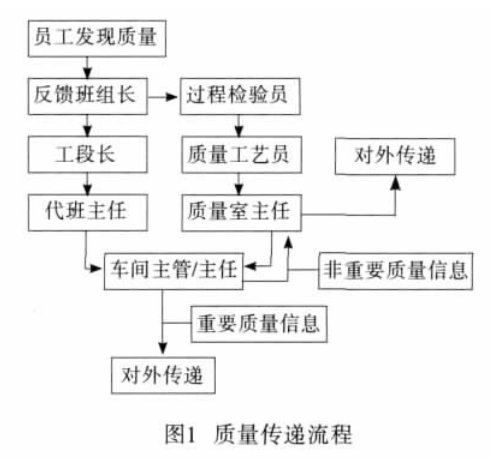

⑴ Determine the quality information transfer process

The mass transfer flow chart of the current paint shop is shown in Figure 1.

⑵Use various conference platforms to communicate

The daily morning meeting/evening meeting not only plays a role in summarizing today and planning for tomorrow, but also an important way for relevant units and personnel to obtain quality information. AUDIT means "audit, verification" in English, and the AUDIT of the car body refers to reviewing the problems of the car body with the most critical eyes of customers. The painting workshop conducts AUDIT audit on the painted body every day, aiming to find out the quality problems in the process and solve them in time. At the same time , relevant leaders will participate in the AUDIT audit meeting, which will play an important role in the advancement and resolution of the problem.

(3) Establish a reasonable performance evaluation mechanism

A reasonable and effective performance evaluation mechanism can form to promote the rapid resolution of quality problems.

5 Conclusion

The quality of coating involves many aspects . The above is the experience summed up after long-term on-site work. It is hoped that it can provide some reference for the quality control of coating on-site effect.

- 1Railway bridge painting quality inspection

- 2Automobile painting two pulp coating sanding

- 3Car painting topcoat lame plating

- 4Automotive repair coating process

- 5Car painting small surface and the whole surface paint precautions

- 6Auto parts coating process

- 7Car painting commonly used lame plating equipment

- 8Engineering machinery coating process mass control

徐来 - 《工程机械漆后装配涂装质量的控制》

- 9Introduction to car body painting process