Types of drying rooms and drying process

Drying room type

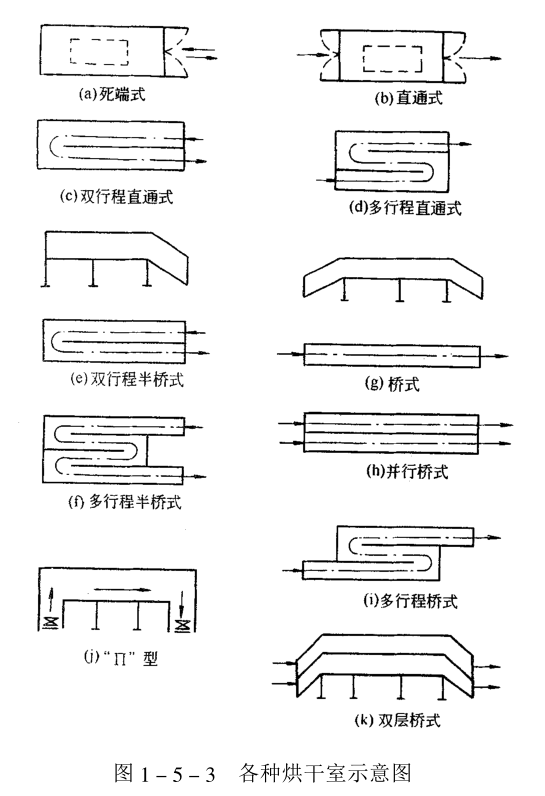

According to its shape, the drying chamber has two types: dead-end type and pass-through type. The dead-end type is used in the intermittent production mode, and the pass-through type is used in the assembly line production mode, and there are differences between single-stroke and multi-stroke. According to the shape , the pass-through type can be divided into straight-through type, bridge type and "II" shape. Generally, the through-type drying room has a large heat spillage, but the equipment is relatively short; the bridge-type drying room is longer and has a higher space. . But the heat spillage is small; "II" type drying chamber is similar to the bridge type except that the length is shorter than the bridge type. The structure of the single-stroke drying chamber is relatively simple, but the equipment is long and occupies a large area; the structure of the multi-stroke drying chamber is relatively complex, the equipment is short, and the floor space is reduced, which is beneficial to the layout of the workshop; parallel equipment is conducive to improving heat preservation And reduce the occupied area; the double-layer drying room can make full use of the space height and reduce the occupied area. Various baking

Schematic view of dry chamber

drying process

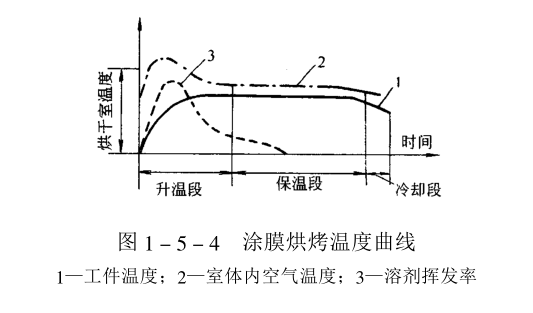

The entire drying process of the coating film in the drying chamber goes through three stages of heating, heat preservation and cooling. In the heating section, the coating temperature gradually rises from room temperature to the drying process temperature, so that more than 90% of the solvent in the wet coating film is here The time required is about 5 to 10 minutes. The length of time is determined by the absence of appearance defects in the coating film . Generally, the heating time of high-boiling point solvents can be short, and the heating rate of low-boiling point solvents should be slow to avoid solvent boiling.

Since the solvent evaporates quickly in the heating section, it is necessary to strengthen the ventilation to remove the solvent vapor and replenish fresh air. In addition, heating the workpiece consumes a lot of heat, so most of the heat is consumed in the heating section during drying.

In the heat preservation stage, the heat preservation time is determined by the curing process time required for the chemical crosslinking reaction of the coating film , and less heat and fresh air are needed to compensate for the exhausted solvent gas. The cooling section adopts a forced cooling method to rapidly cool the workpiece below 40°C, so that the next process can be carried out immediately to ensure the normal operation of the assembly line. If natural cooling is adopted, it will take 20~30min to drop to 30~40℃, which can only meet the batch production mode.

The drying chamber is divided into convection type, heat radiation type and radiation convection composite type according to the heating method.