What is a Digital Multimeter? (principle, purpose)

Overview of Digital Multimeters

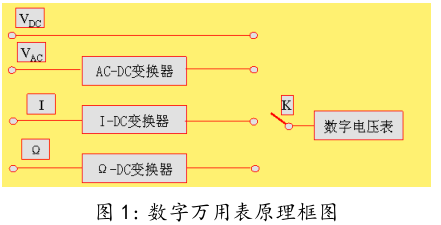

When measuring, the measured value is first converted into DC voltage through different converters, and then the voltage is measured with a digital voltmeter to obtain the measured value. Therefore, the core of the digital multimeter is a DC digital voltmeter. The measurement process of the DC digital voltmeter is to use the A/D (analog/digital) converter to convert the measured analog voltage into a corresponding digital quantity, then count through the electronic counter, and finally directly display the measured voltage value in the form of decimal numbers on the monitor.

The purpose of digital multimeter

The digital multimeter can not only measure AC and DC voltage, AC and DC current and resistance, but also measure capacitance and signal frequency, and judge whether the circuit is on or off.

The principle of digital multimeter

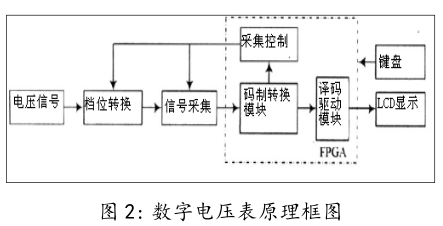

First, the measured voltage signal enters the A/D converter, and the control signal module in the FPGA sends a control signal to start the A/D converter for conversion, and the digital signal data obtained by sampling is converted into a display code in the corresponding code system conversion module . Finally, the decoding drive module sends display control and drive signals to drive the external LCD module to display the corresponding data. Through the external keyboard, you can manually reset the system and select gears. Different gears determine different voltage input ranges, and automatic conversion is realized in the program. The block diagram of the basic working principle is shown in Figure 2.

- 1How to measure the digital multimeter? What are the precautions?

- 2How to choose a digital multimeter?

- 3Application Scenario Collection of Ulide Industrial Digital Multimeter

- 4Multimeter measurement principle

严明忠 - 《中小企业管理与科技旬刊》

- 5Maintenance of Common Malfunctions of Digital Multimeter

赵进春;杨世伟 - 《计量与测试技术》

- 6How to Use Digital Multimeter and Precautions for Use

杨红英 - 《科技资讯》

- 7How to Choose a Digital Multimeter?

杨红英 - 《科技资讯》

- 8Maintenance and Repair of Digital Multimeters

- 9How Digital Multimeters Work and Use