Introduction to Optical Properties Test Method of Coatings

dry hiding power

Dry hiding power is also called contrast ratio. Prepare the white test paint on the picture of Leneta 3B into a uniform coating film with a thickness of 3 mil (1 mil ≈ 25.40 μm). Measure the Y-reflectance on the white and black parts of the picture. The contrast ratio is the ratio of the Y value of the black part to the white part. The higher the contrast ratio, the stronger the hiding power.

wet hiding power

As the name implies, wet hiding power is the contrast ratio of the wet film. Immediately place a perforated plexiglass cover on the coated wet film. The special design of this plexiglass cover allows a certain distance between it and the paint film, and also prevents the contact between the Colorimeter and the wet paint film. Use the Spectrophotometer to quickly measure the Y value in the white and black parts of the picture through the hole. Wet hiding power is calculated the same as dry hiding power.

relative tinting strength

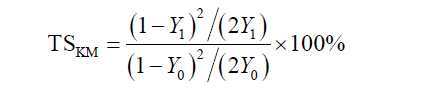

The relative tinting strength was evaluated according to ASTM D4838–88(2010) Standard Test Method for Determining the Relative Tinting Strength of Chromatic Paints, adding 5.0 g of phthalocyanine blue to 250.0 g of test paint and reference paint respectively, and then mixed on a shaker for 5 min . A 6 mil thick film was prepared on the Leneta 3B image and dried for 24 h under constant temperature and humidity conditions at 25 °C and 50% relative humidity. The Y% lightness value is measured according to the XYZ color system (the reflectance of the test paint is represented by Y1, and the reflectance of the reference paint is represented by Y0), and then the relative tinting strength is calculated by the Kubelka-Munk formula

TSKM (%):

Scrub resistance

Relative scrub resistance was tested using a Garner Linear Scrub and Abraser. The preparation of the coating film sample and the testing procedure are as follows: Prepare the coating with a wet film thickness (recommended instrument: wet Film Thickness Gauge) of 7 mil on the Leneta black plastic drawing, and the paint film is kept at a constant temperature of 25 °C and 50% relative humidity. Dry for 7 days under constant humidity conditions. The nylon bristle brushes were run back and forth 400 times prior to testing. The test uses a standardized abrasive scrub medium (Leneta Corporation #SC-2) with 7 mL of scrub medium and 5 mL of water added initially and after every 400 cycles. The test was repeated 3 times for each sample and the number of brush cycles as the coating was worn through was recorded. A scrub resistance control sample was included on each test chart.

For more information, please refer to the full text of "Professional Covering Polymer and New Dispersant Technology to Optimize Covering Power and Reduce Titanium Dioxide Consumption" (Wu Wenjun, Xiong Xizhu, Christine Fortener, Medhi Bouzid, Mike Kaufman, Liu Lili)

- 1Summary of determination methods for hiding power of coatings

- 2Pigment hiding power

- 3Determination of Coating hiding power

- 4GB/T 23981.2-2023: Paints and varnishes - Determination of hiding power - Part 2: Checkerboard method - Interpretation

- 5Concept, influencing factors and determination method of Coating hiding power

- 6Mayer Rods: The right-hand man for hiding power tests

- 7Coating performance testing: ensuring the efficiency and mass of the painting process

- 8Coating hiding power measurement

- 9Application of paint film Applicator in hiding power test

-

-

-

-

Leneta WB sealed film, pure white$ 298.00

-

-