What is airspraying?

Air spraying is a coating method that atomizes the paint by the airflow of compressed air, and sprays it on the surface of the object under the drive of the airflow.

The atomization of paint can be divided into three stages. In the first stage, the paint is sucked from the tank to the nozzle by the high-speed airflow through the small tube, and is immediately surrounded by the annular air flow, causing the paint liquid to start to split. In the second stage, under the impact of the subsequent flow, the paint splits at an accelerated rate. In the third stage, the paint is impacted by the air jet from the horn, making it a fan-shaped mist jet.

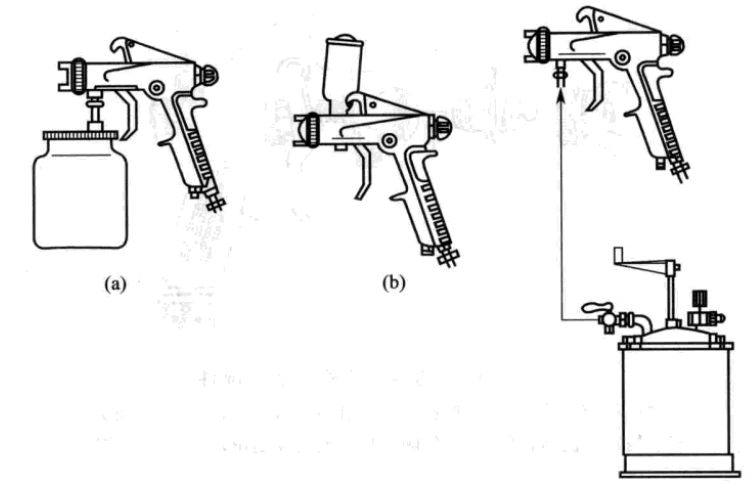

Air spraying is divided according to the way of paint supply and delivery. There are mainly three types of Spray Guns

Three types of Spray Guns for air spraying

(a) suction type; (b) gravity type; (c) pressure feeding type

High volume low pressure (high volume low pressure, HVLP) environmental protection Spray Gun, with very low air pressure [the air cap position is only 0.7 bar (1 bar= 10 5 Pa)] to atomize the paint, reduce overspray, and the transfer efficiency is higher than 65%, It can save paint by 10%~30%. The recommended spraying air pressure is 2.0bar, and the air pressure can be slightly increased to 2.5bar when spraying varnish and plain paint . It is necessary to change the spraying habit slightly. The recommended spraying distance is 13~17cm. When you first use it, you feel that the speed is "slow" and the force is "soft". It needs more and stable compressed air to drive.

- 1The principle and common equipment of airspraying method

- 2Three lame plating methods for fluorocarbon paint painting

- 3Airspraying common faults

- 4Atomization method and characteristics of air Spray Gun

- 5Equipment required for airspraying

- 6Airspraying characteristics and precautions

- 7Summary of high pressure airless spraying tools and construction methods

- 8Airspraying tools and construction methods

- 9Airspraying precautions