Study on the Influence of Different Conditioning Factors on Transformer Umbrella Sleeve Conditioning

0 Preface

In the power industry, equipment such as voltage transformers, current transformers, composite insulators, dry transformers, high-voltage switches, wall bushings, and climbing sheds all use silicone rubber as the outer insulating material. Among them, voltage transformers, Current transformers are used the most. After the transformer has been put into operation for several years, the silicone rubber sheath on the surface will appear pulverized and brittle on the surface, decrease in surface resistance, decrease in hydrophobicity, decrease in flashover voltage, and increase in leakage current under the action of natural environment, high electric field and other factors. Big and other aging problems. The aging degree of transformers with different operating environments and different operating years varies greatly. Under the influence of multiple factors, it is difficult to find out the most essential factors that cause aging. Through experimental research, the factors that are likely to cause the aging acceleration of the transformer sheath are tested separately, and the influence of each factor on the aging of silicone rubber is analyzed, and each aging phenomenon is quantified through various evaluation methods evaluate.

1 Analysis of the aging phenomenon of umbrella cover

1.1 The aging phenomenon of umbrella cover

The aging performance of the silicone rubber umbrella cover is: the surface of the shed is pulverized, loses elasticity, the color turns white, and the hardness increases; under the condition of external force, irrecoverable cracks and cracks will occur. The aging of the silicone rubber umbrella skirt is accompanied by the change of the material itself. When severe aging occurs, its surface resistance and surface hydrophobicity will decrease.

1.2 SEM analysis of aging of silicone rubber sheath

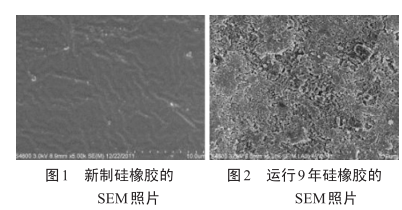

Figure 1 and Figure 2 are the SEM photos of the surface of the newly made silicone rubber and the aging silicon rubber material cut from the transformer after 9 years of operation.

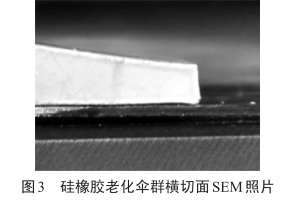

Figure 3 is a cross-sectional view of the silicone rubber umbrella group that has been in operation for 9 years. It can be seen from Figure 3 that the silicone rubber material inside the umbrella group is still dense, elastic, and mirror-like luster, and the aging only occurs on the surface. The measurement shows that the upper surface The thickness of the aging layer is greater than the thickness of the aging layer on the lower surface, and the thickness of the aging layer at the edge of the umbrella group is greater than the thickness of the joint between the roots of the umbrella group and the umbrellas.

1.3 FTIR analysis of aging of silicon rubber sheath of transformer

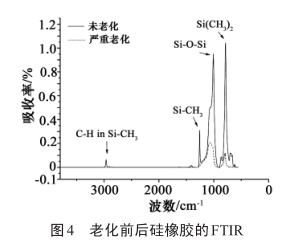

The FTIR of silicone rubber before and after aging is shown in Figure 4. The unaged sample is a new silicone rubber, and the severely aged sample is an aged sample taken from a transformer that has been in operation for 9 years.

It can be seen from Figure 4 that the absorption peak of the Si-O bond of severely aged silicone rubber is wider and its position has changed. The structure of the main chain changes. In addition, the absorption peak of the severely aged silicone rubber sample decreased significantly, and the ratio of the characteristic peaks of Si-C and Si-O was about 1.787~2.436, while the ratio of the unaged sample was 0.912. This is an obvious feature of naturally aged silicone rubber samples, that is, the decline rate of the Si-C absorption peak is much greater than that of the Si-O absorption peak. The reason may be that under natural conditions, the branched organic group is first affected by external factors such as ultraviolet rays, oxygen, and moisture to degrade and break the chain. The group is stable and requires higher activation energy to degrade and break the chain. Therefore, it can be considered that the aging cracking of silicone rubber is mainly caused by the breakage of the organic group on the siloxane side chain.

2 Aging test

2.1 Xenon lamp aging test

The composite insulating sheath is an organic material, and the main factors causing its aging include ultraviolet rays, oxygen, ozone, moisture, temperature changes and industrial pollution, etc., and the ultraviolet rays in sunlight are the most important factors causing the aging of polymer organic materials[5- 6]. The xenon lamp tube has the characteristics of strong irradiating power and similar spectral distribution to sunlight, so it is suitable for simulating the aging process of silicone rubber materials under sunlight. The test uses a water-cooled xenon lamp aging chamber manufactured by Hefei Saifan Test Equipment Co., Ltd., with a xenon lamp power of 6 kW and a maximum irradiance intensity of 1.8 kW/m 2 . A group of 200 h was used as a xenon lamp aging test, and the total amount of radiation was about 1 152 MJ/m 2 . According to GB/T 3511-2008 "Weather Resistance of Vulcanized Rubber or Thermoplastic Rubber", the radiation value is about The total amount of solar radiation received in 4 months.

2.2 Damp heat aging test

Most areas in southern my country are located in subtropical regions with high temperature and high humidity. This climate condition may also be one of the factors causing the aging of silicone rubber. The experiment simulated the high-temperature and high-humidity environment in the southern region. A biochemical Incubator was used to keep the temperature at 40 °C, and a saturated saline solution was used to control the environmental humidity. The silicone rubber sample was placed above the saturated saline solution. In the test, saturated NaCl solution and saturated K 2 SO 4 solution were used to keep the samples at relative humidity of (74.7±0.2)% and (96.4±0.4)% respectively, and a constant temperature and humidity aging test was carried out for 4000 h.

2.3 Corona aging test

The transformer is operated in a high electric field environment for a long time, and partial discharge accelerates its aging. The corona aging test was carried out by using a multi-pole tip-plate electrode to generate corona. The sample size was 150 mm×150 mm×2 mm. Two sets of tests were carried out for 120 h and 240 h respectively, and the test voltage was 6 kV.

2.4 Outdoor aging test in natural environment

The outdoor aging test in natural environment[11-17] can truly reflect the aging condition of the transformer in outdoor operation. Outdoor natural aging is the result of the combined effects of light, temperature, humidity, oxygen flow rate and other factors. The new silicone rubber samples made in the laboratory were placed on the roof platform in the open air to expose them to the natural environment, and the performance of the samples was tested every 2000 h. Shenzhen City is located at 22°27′~22°52′ north latitude. In order to achieve a good aging effect for the samples, the sample rack is placed facing the southeast, with an inclination angle of about 22°.

2.5 Indoor aging test in natural environment

Place the self-made silicone rubber samples directly in a cool place indoors, avoiding direct sunlight, and conduct a performance test every 2000h.

3 Aging test results and analysis

The new silicone rubber samples are self-made according to Dow Corning HVI 1541/10P two-component addition type liquid silicone rubber.

3.1 Hardness

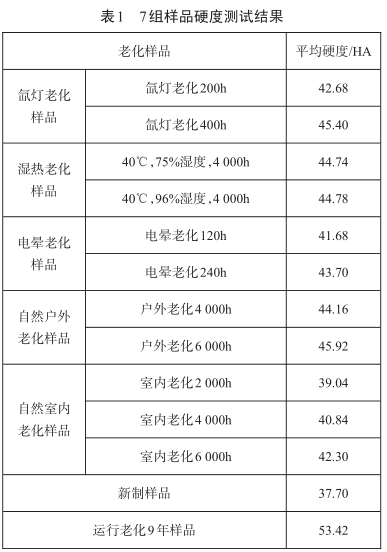

对每组老化试验都取5片样品,在每片样品的不同位置进行6次测量,取6次测量结果的平均值作为每片样品的表面硬度,试验结果见表1。从表1可以看出,新制造硅橡胶的邵氏硬度为37.7 HA,与新投入运行的互感器伞套硬度37.0 HA接近。氙灯老化400 h后样品的硬度(45.40 HA)接近自然老化6 000 h的硬度(45.92 HA),说明光照是硅橡胶老化的重要原因,湿热老化 4 000 h 样品的硬度(44.78HA)比自然户外老化 4 000 h 样品的硬度(44.16HA)略高但不显著,说明湿热有加速样品老化的作用,而在75%湿度和96%湿度下样品的硬度几乎无区别。电晕老化时间从120 h增加到240 h,样品的硬度从41.68 HA增至43.70 HA,说明电晕老化对硅橡胶产生一定影响,其硬度较接近户外老化4 000 h样品的硬度(44.16 HA),也说明电晕对硅橡胶老化产生影响。自然户外老化环境下老化样品的硬度高于室内温和环境下老化样品的硬度,说明光照、雨水、氧气流速等因素会加速硅橡胶老化。

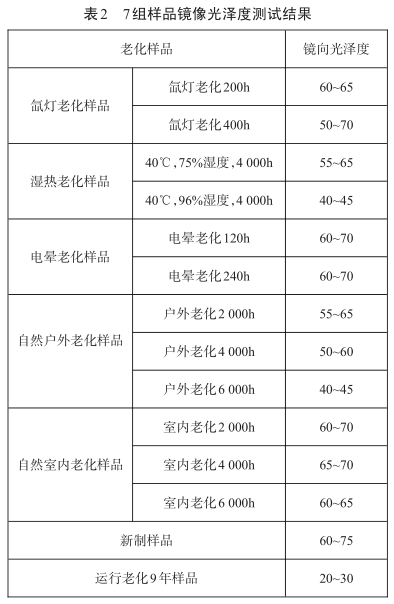

3.2 镜向光泽度

硅橡胶材料的表面状况也能反映硅橡胶老化情况,因为老化硅橡胶样品表面会出现细小的裂痕,导致样品表面粗糙度上升,表面光泽度下降。使用型号为WGG60-E的表面光泽度计对老化样品进行测试,测试结果见表2。从表2可以看出,新制硅橡胶的镜像光泽度最高,湿热老化对镜像光泽度的影响最大,96%湿度下老化4 000 h后样品的镜像光泽度从75下降至40。随老化时间的持续,氙灯紫外老化因素对硅橡胶镜像光泽度影响不明显,自然户外老化时样品的镜像光泽度持续下降。

镜像光泽度表征样品表面的老化程度,可较好的区分且操作方便。但当被测试样品表面未出现粉化层时,测量结果差异不大。

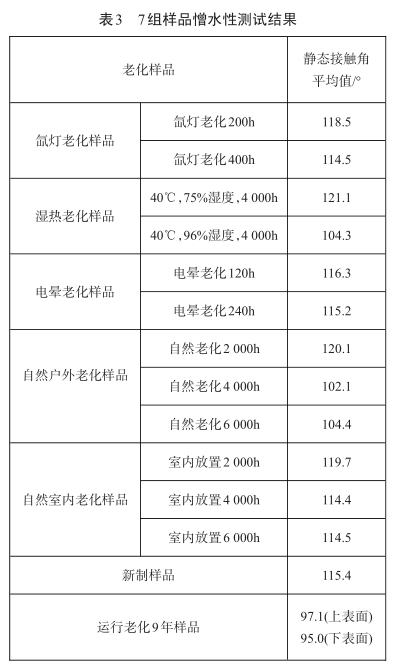

3.3 憎水性接触角

优异的憎水性是硅橡胶被应用于互感器外绝缘护套的重要原因。憎水性可提高护套的污闪电压,降低护套的表面泄漏电流,用憎水性评价互感器的运行老化情况是非常有效的方法 [19-24] 。7组样品的憎水性测试结果如表3所示。从表3可看出,在老化初期硅橡胶的憎水性不但未降低,反而升高,这也与运行中的互感器、绝缘子等硅橡胶制品情况一致,其原因可能与硅橡胶材料具有的憎水性迁移特性有关。随着老化时间增加,憎水性均有逐渐下降,湿热老化与自然户外老化憎水性下降最为明显,静态接触角分别下降至104.3°和102.1°。湿热环境下样品憎水角下降是因为硅橡胶材料在此环境下憎水性会部分丧失,但在重新置于干燥环境下16 h后,憎水性即可回复,考虑到互感器实际运行环境极少会连续出现超过4 000 h(167 d)的高湿环境,因此湿热环境不会严重影响材料的憎水性。自然户外环境下憎水性下降明显,说明多种老化因素共同作用对其影响较大,此外自然户外环境下样品表面污秽累积也是导致憎水性下降的一个原因。

3.4 表面电阻

采用测量表面电阻的方法来测定硅橡胶的绝缘电阻。使用直径约2.5 cm的圆形模具,紧压在硅橡胶伞裙表面,沿圆周在伞裙表面涂抹导电胶,直至形成环形导电带。将一个测量电极置于圆环正中央,另一个测量电极置于圆环导电胶上,加压进行测量,测量结果见表4。通过表4可以看出,5种不同老化因素引起的老化均导致硅橡胶材料的表面电阻大幅下降,氙灯老化与湿热老化后表面电阻降低尤为显著,而运行老化9年的互感器伞群的表面电阻较新制硅橡胶已经下降80%。

4 结 论

(1)互感器硅橡胶伞套发生老化时,材料由致密变得疏松多孔,硅橡胶分子的各种官能团红外吸收峰均降低,侧链有机基团降解速度快于主链无机基团,护套的老化主要由侧链有机基团断裂引起。

(2) The xenon lamp aging condition has the most significant effect on the hardness of silicone rubber, and the hardness increases from 37.0 HA to 45.40 HA; the humid heat aging condition has the most significant effect on the mirror image gloss of silicone rubber, and the mirror image gloss decreases from 75 to 40; natural outdoor aging Conditions have the most significant effect on the hydrophobicity of silicone rubber, and the static contact angle decreases from 115.4° to 102.1°; xenon lamp and damp heat aging conditions have the most significant effect on the surface resistance of silicone rubber. In addition, corona aging has a greater impact on various physical and chemical properties. Impact.

- 1Microscope classification, operation and application

- 2Basic Principle, Functional Characteristics and Application of xenon arc aging Test Chamber

- 3Introduction of working principle and application scope of water-cooled xenon arc weathering Test Chamber

- 4The difference between fluorescent UV Lamp and xenon arc: Two Light sources in artificial accelerated aging

- 5Xenon arc weathering vs UV weathering: differences in ray of light simulation

- 6Rubber aging talk: xenon arc aging, ultraviolet light aging, ozone aging

- 7How to use trinocular Microscope

- 8Xenon arc aging Test Chamber common faults and solutions, how to maintain?

- 9Application of xenon arc aging Test Chamber in coil coatings