Floor coatings - topcoats

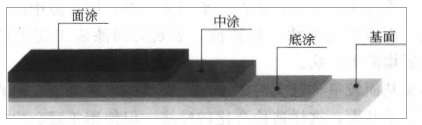

The base surface can be painted with topcoat after priming, intermediate coating, grinding and smoothing. The paint film of the topcoat is generally dense, can resist the erosion of chemical media and solvents, has good wear resistance, and has good mechanical properties, can display colors, and has good decorative effects and protective properties. In addition, special properties can also be provided upon request, such as anti-static (conductive), anti-radiation, anti-skid, etc.

Choose the appropriate construction method according to the construction thickness of the topcoat. When applying thin floor topcoats, stick coating or brush coating is generally used. The coating should be uniform. When the coating coverage rate is poor, it should not be compensated by increasing the thickness, but It should be applied several times. Magnesium knife engraving is generally used when constructing thick floor topcoats (self-leveling flat paints). When the thickness of the applied topcoat is between the two, and its thickness is not enough to meet the self-leveling conditions, spraying is often used to obtain a better surface effect.

The topcoat coating and drying method shall be determined according to the construction environment and the type of coating, and it shall be applied on the intermediate layer or primer that is confirmed to be free from defects and dry. In principle, the second topcoat should be applied after the first topcoat is completely dry.

When coating the topcoat, sometimes in order to enhance the gloss and fullness of the coating, a certain amount of the same type of varnish can be added to the last topcoat of the coating. Sometimes a varnish is applied for protection, and the finish varnish can be different from the original topcoat.

Special care must be taken when applying the topcoat. The topcoat (especially thin floor topcoat) should be carefully filtered with fine mesh or gauze, and the place should be clean and dust-free when painting and drying.

- 1Industrial floor coatings key performance and detection method

- 2Epoxy resin floor coatings key performance and detection method

- 3What is polyurethane floor coating?

- 4What is epoxy floor coating?

- 5Preparation Process of Waterborne Epoxy Floor coatings

- 6Floor coating - medium coating

- 7Floor coating classification