Floor painting control technology

The quality of the coating is related to many factors. To obtain high-quality coatings, qualified surface treatment, good-quality coatings, correct coating processes, and skilled coating techniques are required. The quality control of coating engineering includes comprehensive quality management such as formulation of coating quality requirements, quality inspection, quality information feedback and completed coating protection.

1 Documents to be collected and researched by quality inspectors

The quality inspector should be familiar with the surface treatment, paint application requirements, inspection experimental requirements and relevant standards, and the characteristics of the material to be coated. The following documents should be collected and fully studied:

Technical specifications (including amendments and related accessories);

Relevant regulations and standards (including testing standards, acceptance standards, etc.);

Manufacturer's instructions (including paint and coating equipment, etc.);

Painting regulations (including painting design drawings, painting design process, painting schedule, etc.);

Instructions for use of testing equipment, etc.

2. Testing equipment required for coating quality control

Technical specifications and national standards will specify the required inspection tests, as well as the corresponding inspection equipment. Commonly used inspection instruments are as follows:

Thermometers, including air and surface thermometers;

Hygrometer;

Paint Viscometer;

Thickness gauges, including pan Film Thickness Gauges and dry Film Thickness Gauges;

Coating Gloss Meter;

color difference meter;

Adhesion Tester;

Grounding resistance shaking meter (used for three-pole measurement method) digital megohmmeter for detecting anti-static ground grounding (used for detecting system resistance and surface resistance of anti-static ground, test voltage lOOV, range should be greater than 1. 0 X 103 -1. 0 X 1011 D., the accuracy grade shall not be lower than 2.5 grade);

Electrodes (two, made of copper, should be marked on the surface, cylindrical, 63mm in size, 2.5kg, used together with a digital megohmmeter to detect the system resistance and surface resistance of the anti-static ground). resistance);

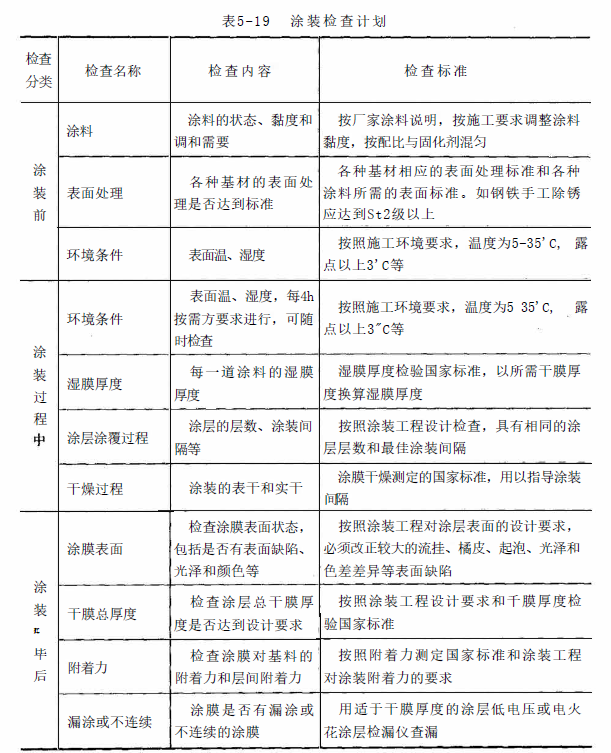

3. Inspection points included in coating quality control

Inspection points depend on the coating material and the type and nature of the job. Most work should be based on checkpoints, and checkpoints can be added as necessary. See Table 5-19 for specific inspection work.

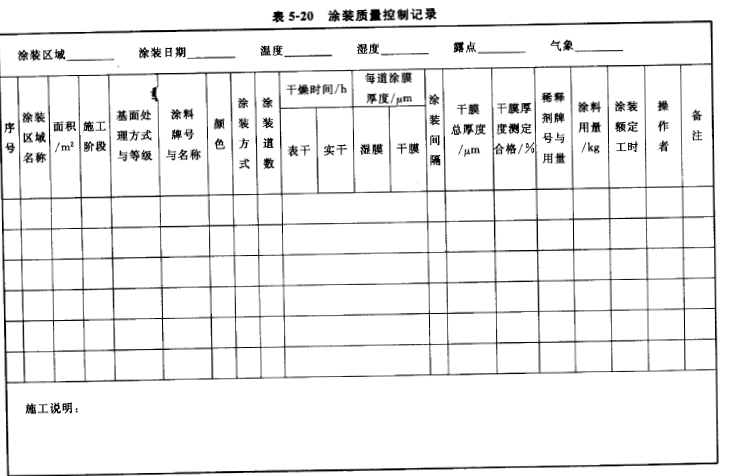

4. Painting quality control table

Taking Table 5-20 as an example, the coating project record that needs to be filled in during the coating process is designed, and this record shall prevail, and the construction quality control shall be carried out by referring to and comparing the corresponding national standards and construction design requirements.

- 1Floor painting equipment and use skills

- 2Floor painting method of painting

- 3Auto parts coating process

- 4Engineering machinery coating process mass control

徐来 - 《工程机械漆后装配涂装质量的控制》

- 5Automotive topcoat layer scratch through the primer coating process

- 6Automotive repair coating process introduction

- 7Introduction of auto parts coating process

- 8Introduction of car body coating processing method

- 9Electro-coating process for coating protection