Test method for yellowing resistance of polyurethane synthetic leather

1. Test method for resistance to light yellowing

The ability of polymer materials to withstand sunlight (or artificial light sources simulating sunlight) to maintain their original physical or chemical properties is called the light resistance of polymer materials. At present, there are mainly four light fastness test methods commonly used in the synthetic leather industry, and they are based on the test methods under four different light source equipment conditions. WOM artificial accelerated aging test, QUV ultraviolet accelerated aging test, UVA ultraviolet lamp light yellowing test, UVB ultraviolet lamp light resistance test 4 basic methods.

1) WOM artificial accelerated aging test

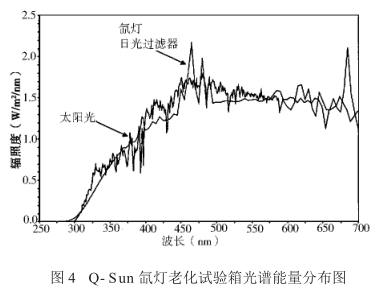

The WOM test is a test method using xenon lamp aging equipment. The Q-Sun xenon lamp aging Test Chamber of Q-Lab in the United States can produce ultraviolet light, visible light and infrared light. Therefore, the Q-Sun xenon arc lamp aging test is considered to be the test method that best simulates the full solar spectrum (as shown in Figure 4). Q-Sun xenon lamp aging can continuously expose the tested samples to the light environment equivalent to noon in summer. Compared with the actual outdoor environment, the average light intensity is stronger and the average daily exposure time is longer. This equipment can simulate the temperature and humidity changes of the environment while performing the light resistance test. Therefore, the Q-Sun xenon lamp aging test can objectively and accurately reflect the color change and aging of materials in the natural environment.

Because xenon lamp aging equipment is relatively expensive and the test conditions are relatively harsh, this method is currently mainly used in the field of light aging test of automotive leather in the synthetic leather industry.

2) Accelerated UV aging (QUV)

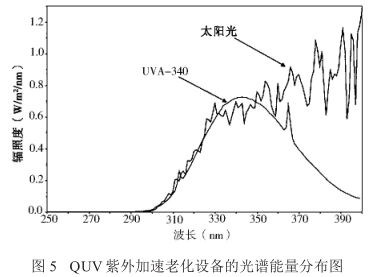

The QUV ultraviolet aging equipment of Q-Lab Company of the United States is based on the principle of short-wave ultraviolet radiation, because short-wave ultraviolet radiation is considered to be the primary factor that causes serious damage to plastics exposed to the outside. Most of the QUV detection equipment used in the synthetic leather industry uses UVA-340 lamps. The spectral energy distribution of UVA-340 lamps is very close to the energy distribution of sunlight in the wavelength range of 290-360 nm, which can simulate the ultraviolet part of sunlight. The effect of damage to the material. At the same time, the QUV equipment is also equipped with a condensation system to simulate moisture erosion in a natural environment. This simulation condition is very similar to natural aging [21].

At present, the QUV Tester is widely used in light fastness testing in various industries, and it is also a testing method commonly used in the synthetic leather industry. It is mainly used for light yellowing detection of shoe leather products, etc.

3) UVA light aging resistance

In addition to Q-Lab's UV testing equipment, Taiwan, CHINA High Speed Rail Corporation's GT-7035UA light resistance Tester is also used in CHINA. It uses an OSRAM ULTRA-VITALUX 300 W UVA bulb. The main spectral energy distribution of the bulb is UVA (315nm~400 nm) band 13.6 W, a small amount distributed in the UVB (280nm~315 nm) band 3.0 W, and the peak is concentrated around 365nm in the UVA band. This equipment does not perform temperature and humidity control on the test product. At present, only individual shoe-making enterprises adopt this test method.

4) UVB photoaging resistance

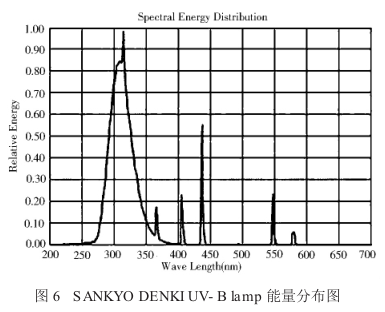

At present, CHINA's synthetic leather industry, especially the shoe leather market in Jinjiang, Fujian, generally uses a UVB lamp yellowing Tester (GT-7035UB light resistance Tester) from Taiwan, CHINA High Speed Rail Company. It uses two Japanese Sankyo Electric Co., Ltd. ( SANKYO DENKI UV-B lamp15W G15T8E *) UVB ultraviolet lamp tube for light aging test, its spectral energy distribution is between 280~360 nm, and the peak is concentrated at 306 nm. UVB lamps are also commonly used accelerated artificial weathering test lamps, which can damage materials faster than UVA lamps because their wavelengths are shorter than those of UVA lamps. Under the same irradiance (light intensity), It can cause deviations from actual test results for many materials. Therefore, the accuracy and reliability of this inspection method remain to be investigated.

* Remarks: It is pointed out that due to the mistakes of equipment manufacturers, the same type of instruments used by many companies do not use standard UVB lamps, but two UVC lamps with a wavelength of 253.7nm, model SANKYO DENKI Germicidal UV- C lamp 15WG15T8 , The results obtained by using UVC lamps for light resistance testing cannot correctly reflect the actual light resistance of the product.

2. Test method for resistance to phenol yellowing

The test method for resistance to phenolic yellowing is mainly aimed at the test method for the yellowing of BHT antioxidants in material products when they are affected by NOx. The experimental device for the phenol yellowing test is basically the same as the commonly used test instrument for color fastness to perspiration. Wrap the sample to be tested and a sample used for time control with phenol-containing test paper and clamp them between glass plates to form a combined sample. After applying a certain pressure, wrap it tightly with polyethylene film and place it in an oven at a specified temperature. , remove after a period of time, disassemble the polyethylene film after cooling, take out the control sample and sample, and immediately use the GB251 gray sample card to evaluate the staining level of the sample.

- 1Non-yellowing Test Chamber comprehensive analysis: test principles, scientific definitions, and professional selection guidelines

- 2The relationship between natural aging and accelerated aging

- 3Artificial climate accelerated weathering test and natural aging conversion

- 4Application of accelerated weathering Test Chamber in respirator

- 5Application and test of UV aging Test Chamber in silicon oxidation

- 6UV accelerated weathering Test Chamber for weathering resistance of epoxy resin

- 7Application of UV aging Test Chamber in sunscreen clothing

- 8Application and test method of UV aging Test Chamber in Aluminum profile

- 9Application analysis of ultraviolet accelerated weathering Test Chamber in PEVA film