Preparation of Waterborne High Transparency Matte Finish

Abstract: Using water-based emulsion, matting powder and other additives as raw materials, a high-transparency water-based matte clear finish was prepared through formula optimization design. The effects of the types of emulsion, matting powder, dispersant, and defoamer on the transparency of the finally developed water-based matte (3-spectrum) clear topcoat were discussed, and the transparency of the coating film was evaluated by combining visual inspection and Colorimeter testing . The results show that when the formula adopts Carpoly emulsion HG-4809, the matting powder adopts OK-607, the dispersant adopts quick and easy dispersant, and the defoamer adopts Tego-810, the film transparency of the final matte clear topcoat is obtained Very good, with a color difference of only 0.17% on a standard black base.

0 Preface

When a beam of parallel light hits a plane mirror, the reflected light is parallel. This kind of reflection is called specular reflection. When a parallel incident light hits a rough surface, the surface will reflect the light in all directions, so the incident light will Parallel, because the normal direction of each point is inconsistent, the reflected light is randomly reflected in different directions. This reflection is called "diffuse reflection" or "diffusion". Specular reflection (see Figure 1) is due to its reflected light The direction of reflection is consistent, and its light intensity is significantly greater than that of diffuse reflection (see Figure 2) [1].

When light hits the surface of an object, part of it will be absorbed by the object, part of it will be reflected and scattered, and part will be refracted. The gloss of the object surface is closely related to the roughness of the object surface. The smaller the roughness of the object surface, the The higher the probability of specular reflection, the higher the gloss; on the contrary, if the surface of the object is uneven, the scattered light will increase, resulting in a decrease in gloss. When matting powder is added to the coating film, due to the difference between the refractive index of the matting powder itself and the film-forming material, the particle size of the matting powder will cause the surface flatness of the coating film to decrease, and there are certain differences in the purity of matting powders from different manufacturers. Light scattering is easy to occur; in addition, the matting agent is not fully dispersed after being added, so that air remains in the dry film, and the difference between the refractive index of air and the film-forming substance is too large, resulting in light scattering, which eventually leads to a decrease in the transparency of the coating film .

According to its gloss, water-based wood coatings can be divided into matte, semi-matte and glossy. At present, matte varnishes are widely used in the furniture coating market. Because of their soft gloss and delicate touch, they are favored by consumers. However, in the actual formula design, there are many problems in the water-based matte varnish, such as the matting powder is not easy to disperse, the storage stability of the paint, the transparency of the final coating film, etc., especially in dark walnut, black brown wood and other deep It is especially obvious on colored substrates, which are often accompanied by disadvantages such as fog, blue light, and whitening, which restrict the market development confidence of water-based wood coatings [2-4]. At present, the evaluation of the transparency of wood coatings largely depends on the accumulated experience of paint practitioners, and there is a lack of corresponding testing standards [5]. big. Zhang Tao[6] made a flat bottom plate with a reflectance of no more than 1% after sealing with black paint, and used a Spectrophotometer to use the bottom plate L*0, a*0, b*0 values as a reference to paint Measure the L*1, a*1, b*1 value of the coating film with a certain thickness after drying, and then calculate the color difference ΔE*, the greater the color difference value, the worse the transparency.

In this paper, the types of emulsion, matting powder, dispersant, defoamer and leveling agent are selected, the transparency of water-based matte clear topcoat is studied, and a more complete transparency evaluation method is established, and finally through the optimization Formulated to develop a waterborne matte clear topcoat with excellent clarity and outstanding chemical resistance.

1 Experimental part

1.1 Test raw materials

Emulsion: HG-4809, HG-4829 (self-produced), Roshield 3188ER, Roshield 3311 (Dow), AC-49 (Esco); matting powder: OK-607, TS-100, TT-3300 (Evonik Gusai), SYLOID ED-3, SYLOIDC-807 (Grace, USA); Dispersant: Happy Dispersant, Orotan 731A (Dow), BYK 191 (Byk Chemicals), H100 (Ocean); Defoamer: Tego 902W , Tego 810 (Dego), BYK 093 (Byke Chemicals), VXW4973 (Cytec Chemicals); other additives.

1.2 Test equipment

High-speed disperser: GFJ-0.4, Shanghai Modern Environmental Engineering Technology Co., Ltd.; wet Film Applicator: 150 μm, Shanghai Modern Environmental Engineering Technology Co., Ltd.; gloss meter: WGG60-E4, Keshijia Photoelectric Instrument Research Institute; Colorimeter: SP 60, X rite; Air Spray Gun: W-77, Japan Iwata Co., Ltd.; Tu-4 Viscometer: QND-4, Beijing Hongzhan Instrument Co., Ltd.; Grating device: HGQ, Shanghai Pushen Chemical Machinery Co., Ltd.

1.3 Preparation formula

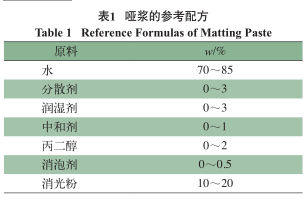

1.3.1 Preparation of dummy pulp

SYLOID ED-3, OK-607, TS-100, TT3300, and SYLOID C-807 were used as matting materials respectively, and mat pulp was prepared according to the reference formula shown in Table 1.

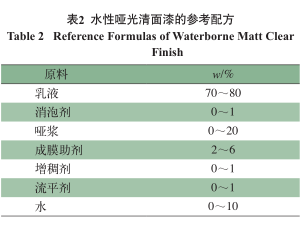

1.3.2 Preparation of water-based matte clear topcoat

Using HG-4809, HG-4829, Roshield 3188ER, Ro-shield 3311, and AC-49 as film-forming substances, water-based matte clear topcoats were prepared according to the reference formula shown in Table 2.

1.4 Analysis and testing

1.4.1 Transparency evaluation of waterborne matte clear topcoat

Take a glass plate of 150 mm×100 mm×3 mm, use a 150 μm wet Film Applicator to scrape and coat a water-based matte clear topcoat, and leave it for 48 hours before use. Observers keep the same distance for visual comparison The clarity of the distant view of the glass plate after scraping and coating with different matte varnishes; at the same time, take the bottom plate with cherry veneer, effectively blow the dust after polishing, and spray two "ten"s of self-produced HD013D primer with better fullness After drying for 2 hours, recoat HD013D primer with 2 "ten" characters. After drying for 3 hours, polish for the second time. After effective soot blowing, spray HD006 + 5% PG094 (black color paste), and the spraying amount is still 2 " Ten" character, air-dried on the surface, after surface-dried, put it into a 50 ℃ drying room to dry for 24 hours, take it out and send it to the woodworking room for sawing to obtain a standard black bottom plate, L * 0, a * 0, b measured with a color difference meter *0 as the benchmark, and then spray the prepared water-based matte clear topcoat on the black base plate to test the color difference with a color difference meter.

1.4.2 Chemical resistance performance test of waterborne matt clear topcoat

Conduct various medium resistance tests on the water-based matte clear topcoat sample prepared in 1.4.1, observe the degree of discoloration after the test is completed, and observe the recovery degree of the coating film after the test is completed.

1.4.3 Other physical and chemical performance tests of water-based matte clear topcoat

水性哑光清面漆的其他理化性能测试按照GB/T23999—2009中规定的方法进行测试。

2 结果与讨论

2.1 消光粉对采用不同乳液制备的水性哑光清面漆光泽的影响

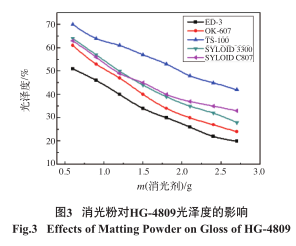

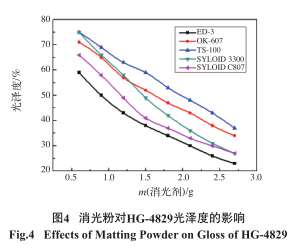

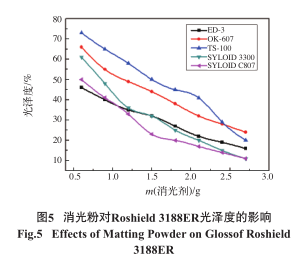

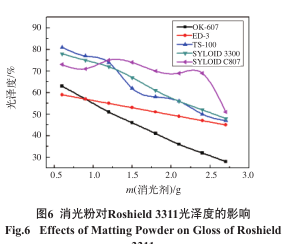

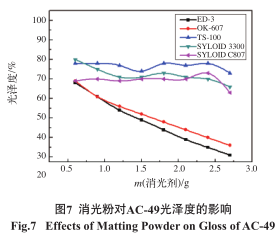

分别以HG-4809、HG-4829、Roshield 3188ER、Ro-shield 3311、AC-49为成膜物质,通过添加不同种类、质量的消光粉,制备水性哑光清面漆,测试的光泽数据列于图3~图7。

试验结果表明:对于HG-4809而言,消光效率排序:ED-3>OK-607>3300≈SYLOID C807>TS-100;对于HG-4829而言,消光效率排序:ED-3>SYLOID C807>3300>OK-607>TS-100;对于 Roshield 3188ER 而言,消光效率排序:SYLOID C-807≈ED-3>3300>OK-607>TS-100;对于Roshield 3311而言,消光效率排序:OK-607> ED-3>TS-100≈3300>SYLOID C-807;对于AC-49而言,消光效率排序:ED-3>OK-607>SYLOIDC807≈3300>TS-100。就总而言之,ED-3、OK-607对以上5种乳液的消光效率较为称心。

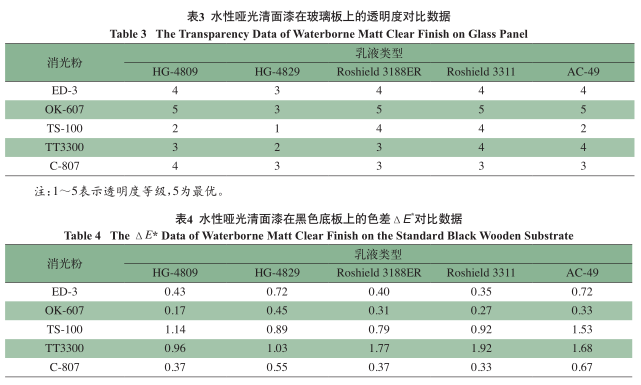

According to2.1中的消光数据,将水性哑光清面漆的光泽统一调节至3分光,同时在玻璃板和标准黑色底板上制备水性哑光清面漆,干燥48 h后测试透明度数据,结果列于表3、表4。

从以上试验结果可以看出,在玻璃板上制备的水性哑光清面漆,在相同的乳液作为成膜物质的前提下,相比其他的消光粉,选择OK-607的透明度更佳,除HG-4829外,其余的4只乳液均表现出优异的透明性,ED-3所制备的哑光清面涂膜的最终透明度在玻璃板上的表现仅次于OK-607;而当水性哑光清面漆在黑色底板上经过喷涂施工后,通过色差仪测试数据表明:OK-607所制备的水性哑光清面漆在黑色底板上罩面之后,对涂膜的色差影响均不大,尤其是当采用HG-4809作为成膜物质时,OK-607所制备出的水性哑光(3分光)清面漆的色差值仅为0.17,而ED-3所制备的涂膜则色差值明显大于OK-607,其在黑色底板上喷涂施工后,肉眼可以明显观测到蓝相,而C-807虽然在玻璃板上透明度表现一般,但在黑色底板施工后的色差却优于ED-3,可能的原因是OK-607是经过了有机表面改性,在体系中具有更好的相容性和更小的吸油量(220 g/100 m),在涂膜干燥成膜过程中不容易析出。故,HG-4809和OK-607为制备水性哑光清面漆较为合适的搭配。

2.3 分散剂对水性哑光清面漆透明度的影响

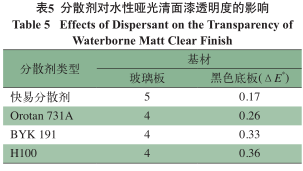

以HG-4809为成膜物质,以OK-607为消光粉,采用不同的分散剂制备了水性哑光清面漆,同时对涂膜在玻璃板和黑色底板上的透明度进行了对比测试,试验结果如表5所示。

从试验结果可以看出,快易分散剂是较为合适的分散剂。可能的原因是快易分散剂的主要成分是聚丙烯酸钠盐,可以很好地润湿消光粉的表面,消除消光粉表面的微泡,使消光粉更好地被包裹在乳胶粒中,实现涂膜相对更加均匀,在涂膜内部不容易发生光的散射,从而实现透明度较好且在黑色底板上色差较小。

2.4 消泡剂对水性哑光清面漆透明度的影响

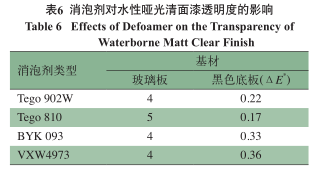

以HG-4809为成膜物质,以OK-607为消光粉,采用不同的消泡剂制备了水性哑光清面漆,同时对涂膜在玻璃板和黑色底板上的透明度进行了对比测试,试验结果如表6所示。

从试验结果可以看出,合适的消泡剂可选用Tego 810,原因可能是相比其他消泡剂而言,Tego810具有更为显著的消泡能力,尤其是消除界面微泡,在涂膜内部的折光系数趋于一致而表现很好差明显更小的优势;而VXW4973作为消泡剂时涂膜的色差值最大,可能的原因是其在体系中的相容性不是很好,造成最终的涂膜存在雾影而影响了透明性。

2.5 水性哑光清面漆的综合性能

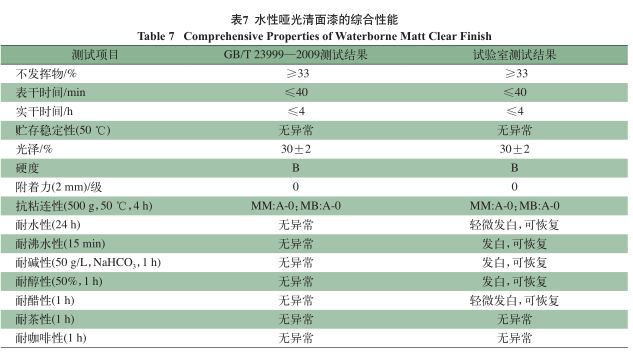

将经过上述配方设计优化后的水性哑光清面漆,按照GB/T 23999—2009的测试项目测试性能,结果如表7所示。

表7中的结果表明,该款水性哑光清面漆各项指标均满足国标,适合工厂用于水性化涂装施工。

3 结 语

采用不同的消光粉和水性乳液搭配,同时讨论了助剂种类对水性哑光清面漆透明度的影响,并最终制备了透明度优异的水性哑光清面漆。

(1)通过消光粉和乳液的搭配试验所绘制的消光曲线可知,ED-3、OK-607对所选用的5支乳液都具有良好的消光效果。

(2)OK-607由于经过了有机表面改性,具有更好的相容性和更低的吸油量,从而能够制备出透明度优异的水性哑光清面漆。

(3)快意分散剂和Tego 810分别是制备水性哑光清面漆较为合适的分散剂和消泡剂。

(4)通过配方设计优化后的水性哑光清面漆,各项指标均达到国标,透明度优异,适合工厂用于水性化涂装施工。

参考文献

[1] BORN M., WOLF E.. Principles of Optics[M].北京:电子工业出版社,2009

[2] 童学平,熊桂蓉,胡爱琼,等.木器哑光涂层透明性的研究[J].上海涂料,2008,46(10):12-13

[3] 史立平,孔志元.水性木器哑光清漆中消光剂的选用[J].涂料技术与文摘,2007,28(4):5-11

[4] 樊新华,裴亚利,张忆.二氧化硅消光粉在木器涂料中的应用[J].现代涂料与涂装,2009,12(7):33-34

[5] 曾敏民,黄智勇,林健辉.影响深色板材涂饰效果的因素分析及对策[J].上海涂料,2008,46(1):31-34

[6] Zhang Tao, Su Zhenxiang. Discussion on the Transparency of Wood Coatings and Its Representation Method [J]. Chinese Paints, 2010,25(3):55-59