Hardness and scratch and wear resistance of water-borne wood coatings

Abrasion is the result of material being peeled off a solid surface under the action of force when two solid surfaces are in contact. In addition to the normal pressure, the force suffered during wear also includes shear force. Exfoliation of material breaks away from the parent material in the form of particles and small pieces. The surface of the material cannot be absolutely flat. From a microscopic point of view, the contact points are some raised tips. When a material has a high hardness or there are rigid particles between the two contact surfaces, the surface will sink after being stressed, and the surface will Subsequent relative movement forms furrowed scratches, which produce scratches. When the surfaces of two materials are in contact, the relatively soft surface is more likely to be scratched. Since the Mohs hardness of the polymer is very low, only 1 to 3, the coating film composed of the polymer is easily scratched. The scratch resistance of hard polymers is related to abrasion and varies in parallel with the modulus of the polymer. The cross-linked elastic polymer is easy to deform and has good resilience, so it has high scratch resistance. Compared with small molecules, another characteristic of polymers is that they are subjected to external forces. When molecules or chain segments move, they need a longer relaxation time. The scratches formed under the action of instantaneous and fast external forces may be caused by the subsequent breakdown of macromolecular chains. The relaxation movement becomes less obvious or even disappears, which is the so-called anti-scratch self-healing coating, and some flexible polyurethane coatings have this function. Of course, if the "furrow" formed by the scratch is too deep, it is difficult to completely heal itself. Scratch resistance reflects the surface properties of a material under high stress for a short time. Scratch resistance is not only related to the hardness of the material, but also related to the toughness of the material.

Abrasion resistance refers to the degree to which the material peels off from the parent body under the same stress conditions (temperature, humidity, contact medium, external force and force time). Like scratch resistance, wear resistance is related to the hardness and toughness of materials, but wear resistance reflects the surface properties of materials under small stress for a long time.

The appearance of the coating film can be roughly divided into hard, soft, tough, and brittle types. The combination of polymer material properties can also form different forms of expression such as hard and tough, soft and tough, hard and brittle, and soft and brittle. . The latter is not uncommon in polymer materials, and even flexible materials can undergo brittle fracture at extremely high acceleration rates.

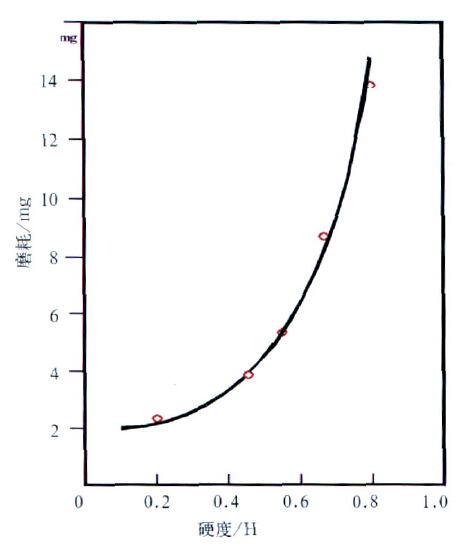

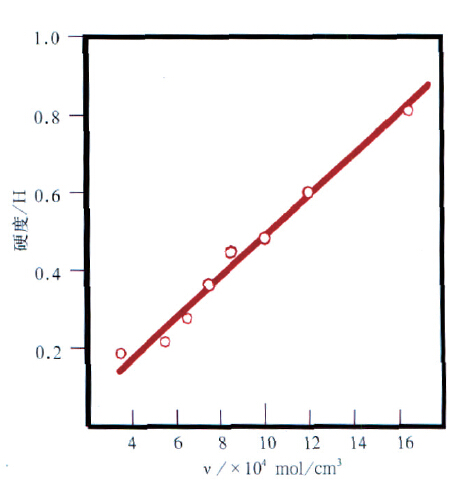

It is not that the harder the coating film is, the better the abrasion resistance is. On the contrary, for the same type of polymer coating film, it has been found that the harder the coating film is, the worse the abrasion resistance is, as shown in Figure 1. The wear value measured under the same conditions in Figure 1 increases sharply with the increase of hardness. In fact, flexible coatings have better abrasion resistance. Since the crosslinking density is proportional to the hardness of the coating film (see Figure 2), it can also be said that the wear resistance of the coating film becomes worse with the increase of the crosslinking density. It can also be seen that the abrasion resistance of the crosslinked coating film is often lower than that of the uncrosslinked coating film. As a coating, a hard and tough coating film is a good coating film.

Fig.1 Relationship between coating film hardness H and wear resistance

Fig.2 The relationship between the pendulum hardness H of the coating film and the crosslink density v

For more information, please refer to the full text of "Hardness of Waterborne Wood Coatings" (Zhu Wanzhang)

- 1Working principle and application of UV coating Cupping testing device

- 2Application of shakeout Tester in organic polymer film abrasion resistance testing

- 3Application of shakeout Tester in aluminum surface coating abrasion resistance testing

- 4Paint film abrasion resistance and test method thereof

- 5Polyethylene (PE) coating indentation hardness inspection and its importance in pipeline corrosion protection

- 6Paint film abrasion resistance and its test method - rubber abrasive wheels method

- 7Determination of abrasion resistance of paint film

- 8Determination method of paint film abrasion resistance and its importance

- 9Coating performance testing: the key to ensuring quality coatings