On-site calibrating for Thickness Gauge measurement

Cladding Thickness Gauges are widely used in production inspection, quality control and quality supervision and inspection in manufacturing, metal processing and chemical industries . With the continuous improvement of the requirements for the measurement and control of the thickness of the covering layer formed by the surface protection and decoration of industrial products , the measurement technology and instrumentation The development is also accelerating, and the measurement of coating thickness has become an important part of the quality control and detection of surface engineering of industrial products.

In the verification work of the cladding Thickness Gauge, the author often encounters problems such as inaccurate measurement and large measurement error when the actual measurement of the cladding Thickness Gauge that has been certified is inquired by customers . Most of these problems are caused by insufficient understanding of the measurement principle and performance of the instrument, and inability to correctly grasp the on-site calibration method of the instrument. In this paper, we specifically discuss the related issues of on-site calibration current measurement. Because the correctness of the on-site calibration method is directly related to the accuracy and reliability of the measurement results.

1. The particularity of the use of the instrument

The use of cladding Thickness Gauge is quite special, it is different from many length measuring instruments. Most of the length measuring instruments can be used directly after passing the verification , and do not need to be calibrated at any time. The particularity of the cladding Thickness Gauge in use is

(1) When measuring the cladding Thickness Gauge, it needs to be calibrated before measuring . Because the accuracy of the measurement results is closely related to the substrate material , the surface roughness of the substrate, the geometry of the part to be tested, and the electromagnetic interference of the surrounding environment. Only by paying attention to these relevant factors and conditions and choosing the correct on-site calibration method can more reliable measurement data and results be obtained.

(2) The cladding Thickness Gauge is divided into five levels Since the cladding Thickness Gauges produced by various manufacturers have different technical parameters and functions, the user must first read the instrument manual in detail, and combine the verification certificate to find out the measuring range of the instrument, the maximum allowable error of the indication value, and the repeatability of the indication value. And other important technical parameters, and measure in strict accordance with the operating procedures in the manual.

(3) The substrate attached to the instrument is mainly used to check whether the instrument is normal , but not to calibrate the instrument during actual measurement, which is not very clear to many users. Often, many users calibrate the instrument with the substrate and the thickness sheet for calibration. If the instrument normal, they start to measure, and the subsequent measurement error occurs. This measurement error is often far greater than the maximum allowable . The reason is that the magnetic induction coating Thickness Gauge is used to measure the thickness of the non-magnetic coating on the magnetic metal substrate, and the eddy current coating Thickness Gauge is used to measure the thickness of the non-conductive coating on the non-magnetic metal substrate. Both are based on the electromagnetic physical properties and the distance between the substrate and the probe to measure the coating thickness. The electromagnetic physical properties and geometric dimensions of the measured substrate will affect the size of the magnetic flux and eddy current, thereby affecting the measurement results and the reliability of the measurement.

For example, the magnetic physical properties of alloy tool steel and low carbon steel are different , and the conductive physical properties of different types of aluminum alloys, copper alloys, etc. are also different, so in actual measurement, the same material as the substrate to be tested should be selected as For the substrate used to calibrate the instrument, it would be better if the same test piece without as the substrate for on-site calibration. Use this matrix and the calibration thickness sheet to calibrate the instrument according to the requirements and regulations of the instrument manual, and then measure. Based on the particularity of the use of cladding Thickness Gauges, on-site calibration during instrument measurement is particularly important. It should be noted that the various are based on the condition that the instrument is qualified.

2. On-site calibration during instrument measurement

2.1 Matrix selection during calibration

(1) In the actual measurement, the same as the substrate for calibrating the instrument.

(2) It should be noted that the surface roughness of the selected substrate is as consistent as possible with the surface roughness of the substrate under test.

(3) The requirement for the minimum thickness of the base metal is also a measurement condition that needs attention. Each instrument and even each probe in each instrument has its own critical measurement thickness of the base metal. Greater than this thickness, the measurement will not be affected by the thickness of the substrate.

(4) Each instrument or even each probe also has requirements for the minimum area of the substrate of the tested piece. If the area is larger than this, the measurement will not be affected by the area of the substrate.

(5) The radius of curvature of the substrate surface also has a great influence on the measurement. Because the instruments all specify the minimum radius of curvature, in actual measurement, in order to reduce measurement errors, the same material with the same radius of curvature as the test piece should be selected as the calibration substrate, and the instrument should be calibrated together with the calibration thickness sheet.

The above (3)-(5) are aimed at the influence of the minimum thickness, minimum area, and minimum radius of curvature of the substrate . When it is lower than the minimum specified requirements, edge effects will occur and affect the measurement results. This is actually due to magnetic flux and eddy currents. The measurement error caused by insufficient cross-section of the carrier. Therefore, in the actual measurement, it is necessary to avoid measuring at the edge of the specimen, corners, holes, cavities and other positions where the surface shape changes suddenly. If unavoidable, the instrument can only be measured after it has been pre-calibrated on an uncoated surface under the same conditions .

2.2 One point calibration method

Zero calibration

Before the measurement, although the instrument has passed the verification, due to the particularity of the cladding Thickness Gauge, it is still necessary to calibrate the instrument at zero point. The key to zero point calibration is to choose the correct substrate. Only when the zero point of the instrument is calibrated on the correct substrate can the measurement be guaranteed . At this time, the measurement error can basically be controlled within the maximum allowable . However, some instruments have poor stability, and it is not enough to only do zero point calibration . Other corresponding calibrations should be done according to the requirements of on-site measurement, so as to ensure the accuracy and reliability of the measurement results. There are also some special cases where the measurement alone is not enough for zero point calibration, for example, the surface of the substrate is relatively rough, the geometry of the part to be measured is relatively special, etc.

One-point calibration without zero-point calibration

This kind of calibration is often used in batch inspection of products or parts. For example, the coating thickness of a certain product or component is required to be mixed, and the purpose of inspection is mainly to judge whether the product is qualified or not. At this time , as long as the thickness sheet close to Bay is selected and placed on the correct substrate for calibration, the measured value of the instrument is adjusted to the actual , and the measurement can be carried out. As long as the measured value is equal to the qualified product, the work efficiency of the inspection can be improved.

2.3 Two-point calibration method

Two-point calibration with zero calibration

For some instruments, this calibration is required . In general, the instrument is provided with a slice of thickness close to or equal to the maximum value of the measuring range of the instrument. First use the instrument to calibrate the zero point on the correctly selected substrate, then use the maximum thickness sheet to calibrate the instrument, adjust the measured value of the instrument to the actual value of the thickness sheet, and then start the measurement. Within the measurement range of the instrument, the measurement error can basically be controlled within the maximum allowable error of the instrument.

The other kind of calibration is based on the requirements of measurement, only two-point calibration of zero point and a certain thickness value. This situation often requires the instrument to have relatively high accuracy within the measurement range of these two points. First calibrate the zero point of the instrument , and then use the selected thickness sheet to adjust the measured value of the instrument to the actual value of the thickness sheet, and then the measurement can be carried out.

Two-point calibration without zero calibration

This calibration is often used where a range of cladding thicknesses is required . For example, the coating thickness of a certain part is required to be the same , and the measurement accuracy is required to be higher, which cannot be satisfied only by the maximum allowable error of the instrument. At this time, this two-point . Choose the right substrate and approach, . For the two thickness sheets, first use the thinner thickness sheet to calibrate the instrument, and then use the thicker thickness sheet to calibrate the instrument, that is , adjust the measured values of the instrument at these two thicknesses to the actual value of the thickness sheet , can be measured.

This kind of calibration is also often used for batch inspection of product and component cladding thickness to improve work efficiency. Some cladding Thickness Gauges have tolerance bandwidth setting and alarm function. When measuring, as long as the measured value exceeds the tolerance range, the instrument will sound an alarm, which is very convenient and quick for the inspection that only judges whether it is qualified or not. You only need to select a calibration sheet with a thickness close to the two ends of the tolerance bandwidth to perform two-point calibration on the instrument, and then set the tolerance bandwidth for the instrument to perform measurement, which is both accurate and effective.

The two-point calibration method is also suitable for the case where the surface of the substrate is sandblasted and relatively rough. Due to the relatively large dispersion of measured values, when calibrating , whether it is zero point calibration or a certain thickness value calibration, it should be measured once, and the average value of the measured values should be used to calibrate the instrument. When measuring, the average value of multiple measurements should also be used as the measurement result.

2.4 Multi-point calibration method

According to different instruments, the number of calibration points in this calibration method is different, and some multi-point calibration belongs to the basic calibration of the instrument.

Multi-point calibration with more than three points

This kind of calibration is suitable for occasions where the shape of the measured piece is relatively special, and the range of coating thickness is relatively large, and at the same time, high . Users can choose multiple calibration points according to measurement requirements, and some instruments can reach up to three calibration points. Usually the zero point of the instrument , and then according to the selected thickness sheet, the instrument is calibrated according to the thickness value from small to large. After the measured is adjusted to the actual value of the thickness sheet, Measurements can be made.

basic calibration

Basic calibration is a systematic calibration of the instrument. Through this calibration, the indication error of the instrument does not exceed the maximum allowable error within the entire measurement range. This kind of calibration is often used when the instrument is found to have a large measurement error during on-site measurement. Although the instrument has passed the verification and is within the validity period of the verification, but due to the wear of the top of the probe or the long-term non-use of the instrument, the error of is out of tolerance. At this time, a basic calibration of the instrument is required.

Basic calibration depends on different instruments, generally using a thickness slice. According to the operating requirements of the instrument manual, first calibrate the zero point on the substrate, and then place the thickness sheets on the substrate from small thickness sheets. After the calibration is completed , the measurement error of the instrument can be kept within the specified maximum allowable error within the entire measurement range.

由于校准和基体的选用有密切的关系 ,经过基本校准后 ,仪器在测量前 ,只要选用正确的基体校准好零点 ,测量时一般情况下 ,仪器的测量误差不会超过最大允许误差 。但在长期的工作实践中也发现 ,仪器在经过基本校准后 ,在不同的基体上 ,先校准好零点 ,然后放上相同的一组标准厚度片进行测量 ,有的就出现测量误差超过最大允许误差 的情况 。如笔者选用一台电涡流式覆层测厚仪 ,仪器为检定合格 ,准确度为B级 ,最 大允许误 差 为±(1±0.03H) , 为标准片的厚度值。用不同的铝合金材料的基体进行校准 、测量 ,得到的试验结果和数据分析如下

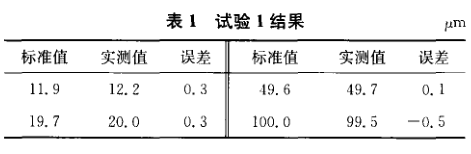

先用仪器自身带的基体和校准用厚度片对仪器作基本校准 包括对零点和20/50/100μm位置的一组校准 ,再把检定用的标准片放在仪器 自带基体上进行测量 ,测量结果见表 。

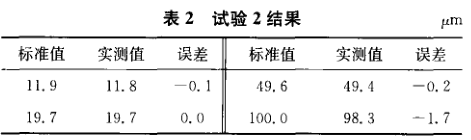

(2)在(1)的基本校准情况下 ,先用基体 对仪器作一个零点校准 ,然后把标准片放在基体 上进行测量 ,测量结果见表 2

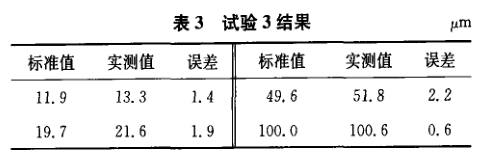

(3)在(1)的基本校准情况下 ,先用基体 对仪器作一个零点校准 ,然后把标准片放在基体 上进行测量 ,测量结果见表 。

表(3) 一 中的实测数据均为 次测量的平均值 。

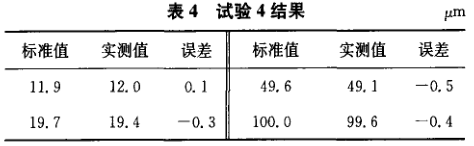

从上述试验结果可以看出,在使用基体 测量时 ,表 中的前两组数据的误差值已超过了仪器的最大允许误差 。在此试验中使用的基体 和基体虽是同一家仪器公司生产的 ,几何尺寸都一样 ,显然所用铝合金材料不一样 。因此 ,在基体材料改变的情况下如发现仪器的测量误差过大 ,就需要对仪器作一个基本校准 ,仪器的测量误差才能控制在最大允许误差之内。表 是在用基体 对仪器做了一次基本校准后再进行测量得到的数据 。

从这组数据可看出 ,测量误差已大为减小 ,全部小于仪器最大允许误差 。

2.5复合校准方式

这种校准方式适用于复合覆层厚度测量时的校准川 。例如 测量带有涂层的镀锌钢板的涂层和镀锌层的厚度 。这种测量需要同时应用磁感应测量原理和电涡流测量原理 。现在已经有集这两种测量原理为一身的覆层测厚仪 ,有的需要更换探头 ,有的无需更换探头 。当然也可用两台不同测量原理的仪器来实现这种测量 。

将两用仪器设置成磁感应测量原理或直接用磁感应测量原理仪器在钢板基体上校准 ,校准方式可According to实际情况在上述校准方式 中选取 ,校准完后即可进行测量 。这时可测出涂层和镀锌层的总厚度 。

Set the dual-purpose instrument to the eddy current measurement principle or directly use the eddy current measurement principle instrument, select the uncoated galvanized steel plate as the substrate, and then calibrate. Similarly, the calibration method can be selected from the above calibration methods according to the actual situation , and the measurement can be performed after the calibration is completed. At this time, the measured value obtained is the thickness value of the coating. Galvanized layer thickness-thickness 1-thickness 2.

epilogue

The calibration of cladding Thickness Gauge is very important, it is directly related to the accuracy and reliability of the measurement results. Although the various calibration methods mentioned above are relatively comprehensive, each instrument only has some of them , and some instruments also have other special calibration methods. Although there are many types of cladding Thickness Gauges with different functions, the basic measurement roughly the same. As long as you understand the measurement principle and master the performance of the instrument, you can correctly select the calibration method during measurement to reduce the measurement . Improving the measurement efficiency can give full play to the measurement ability , making the cladding Thickness Gauge truly an important means to ensure the quality of industrial products.

- 1Basic Principle, Characteristics and Application of Rubber Coating Thickness Gauge

- 2Principle, Characteristics and Application of FISCHER Coating Thickness Gauge

- 3Several Selection Points of Split Coating Thickness Gauge

- 4German EPK company McCourt automatic cladding Thickness Gauge operating instructions

- 5Talking about the particularity of the measurement of the cladding Thickness Gauge and the choice of the substrate when calibrating

张国恒 - 《覆层测厚仪测量时的特殊性及校准时的基体选择》

- 6What affects the measurement accuracy of the cladding Thickness Gauge?

张启忠 - 《河南科技》