Tinplate film physicochemical index mass problem

1. Adhesion

After the tinplate printed matter becomes a finished product, it needs to be transferred to the next process for mechanical processing. If the adhesion of the tinplate printed matter printing and coating is poor, it is easy to damage and fall off the printing layer and coating during the machining process. There are many factors that affect the adhesion of tinplate printing coatings, and different measures should be taken for different situations.

(1) The amount of oil applied to the oil film layer on the iron surface. The main function of the oil film on the tinplate is to prevent the corrosion of the tinplate during storage and transportation. An excessively thick oil layer will affect the wetting of the resin coating on the surface of the tinplate. In order to check whether the amount of oil applied to the tinplate is appropriate, you can first take a small amount of paint and pour it slowly on the surface of the tinplate. If the paint is round on the surface of the tinplate and spreads around, then lift up the tinplate so that it is at 45° to the plane. At this time, if the paint can evenly flow to the lower end, it means that the amount of oil applied to the oil film layer on the surface of the tinplate meets the requirements of the printing and coating process. Otherwise, it is necessary to pre-bake the tinplate (baking temperature: 95~200°C) to solve the problem of poor adhesion. In addition, the thinner the oxide film on the surface of the tinplate, the better the adhesion of the coating on its surface. Therefore, for printed matters with a relatively high degree of machining, it is necessary to choose a good tinplate material.

(2) Printing and coating baking temperature factor. Only a suitable baking temperature can make the resin in the ink and paint solidify the conjunctiva. In actual production, the main factor affecting the adhesion of the printed coating film is often the low baking temperature. The chemical bonds in the resin are not fully cross-linked and solidified, which causes tinplate adhesion and makes it difficult to separate the tinplate. If it is detected that the adhesion cannot meet the machining requirements of the product during production, the baking temperature should be increased appropriately; for the coated tinplate product, drying it again at an elevated temperature can also improve its adhesion. When heating up, pay attention to the temperature not rising too high. Excessively high baking temperature will easily make the printed coating embrittled and easy to fall off during machining.

(3) Coating film thickness factor. The thinner the coating, the better the adhesion of the coating on the tinplate surface. For tinplate with poor surface performance, reducing the thickness of the coating film can improve the adhesion without affecting other properties of the coating film. When the thickness of the coating film required by the process and the adhesion cannot meet the requirements, it can generally be divided into two coatings. The baking temperature of the first coating film is lower than the theoretical temperature of 20°C, so that the structure between the resin molecules is relatively loose. It is conducive to the penetration of resin molecules into the loose structure of the first coating film during the second coating film to improve the adhesion of the coating film.

(4) Printing and coating raw material factors. The printing and coating materials produced by different manufacturers have different prices and different performances. Therefore, in production, it is necessary to have a multi-faceted understanding of the performance of the raw materials used. When encountering products with relatively high mechanical processing requirements and the adhesion cannot meet the processing conditions, switching to high-quality printing and coating materials will help improve the adhesion of the tinplate coating film.

2. Corrosion resistance

The corrosion resistance of the inner coating film of tinplate is an important index to ensure the quality of canned food. How to improve the corrosion resistance of the inner coating film has always been a concern of tinplate can manufacturers. The main function of the tinplate inner coating film in food packaging is to prevent the canned contents from passing through the coating film, dissolving the tin layer and oxide film layer and corroding the steel base of the tinplate, causing the inner coating film to fall off. Prolonging the process of food production, transportation, Shelf life during storage and consumption. Corrosion of the inner wall of cans is mainly affected by the following factors.

(1) Tinplate After the surface passivation treatment, the tinplate has corrosion resistance, but due to the process of processing, the passivation treatment layer is easily damaged and gradually corrodes after the can is made. The oxide layer and tin layer also have an impact on corrosion, the thicker the oxide layer and tin layer, the stronger the corrosion. But the oxide layer is too thick. The adhesion of the coating film coated on the surface of the tinplate will be poor.

(2) Canned contents

a oxygen. Oxygen has a strong oxidation effect on tin in the acidic medium of the can.

b acid. The composition of acids in food varies, among which oxalic acid, fumaric acid and fumaric acid are the most corrosive.

c low methoxyl pectin. Can promote the corrosion of tin.

d Shoalate ion. There is a lot of residual oxygen in the tank. The amount of dissolved tin caused by nitrate radicals increases significantly when the daily value of medium p is below 5.

e anthocyanin. Red fruits such as cherries and kudzu contain anthocyanins, which are acceptors of tin and hydrogen, and the final result can perforate the iron sheet.

f caramel. It has obvious corrosive effect on canned fruit packaging.

g Sulfur and sulfur-containing compounds. is a factor that promotes corrosion.

h copper ions. Copper ions will peel off the tin layer in acidic medium, and can locally corrode iron to cause perforation.

iOxide trimethylamine. The trimethylamine oxide contained in the fish meat can be reduced to trimethylamine, so that the tinplate corrodes to the tin-iron alloy layer without generating hydrogen gas, and loses the effect of cathodic protection.

j Ascorbic acid. Ascorbic acid is easily converted into dehydroascorbic acid during processing, which also loses its cathodic protection effect and may become a highly corrosive factor.

(3) Processing conditions

a additive. In colored food packaging, some additives are often added to protect the color and flavor of the food. For example, adding sulfite can improve the color of the food, but the decomposed sulfide gas will cause the inner wall to turn black.

b type of paint. Different resin coatings have different porosity formed by resin polymers after conjunctiva, so the difficulty of canned contents passing through the coating film is different, and the dissolution rate of tin is also different. Practice has proved that for the coating with the same coating thickness, epoxy phenolic resin has low post-conjunctival porosity and strong corrosion resistance.

c Coating film thickness. The thicker the coating film, the lower the porosity when the resin polymer polymerizes the conjunctiva, which can effectively prevent the contents of the can from passing through the coating film and improve the corrosion resistance of the coating film.

d the mass of the tank. Empty cans are easy to corrode after being scratched, especially canned bamboo shoots, mushrooms, water chestnuts, fish and meat.

In the coating production of tinplate inner coating film, it is necessary to select the appropriate tinplate raw material, coating material and coating film thickness according to the composition of the product into the can. Tinplate coating cans that meet the needs of food packaging can only be produced by adopting appropriate process production methods and testing methods. The specific measures are as follows.

(1) Choose the tinplate. According to the nature of the canned contents, select the tinplate with strong corrosiveness, and use the tinplate raw material with high tin plating.

(2) Select the raw materials for coating. In the currently commonly used interior coatings, it is generally believed that epoxy phenolic resin has good corrosion resistance to acidic food, and the epoxy resin polymer has good adhesion and flexibility; acrylic resin has good flexibility and is very flexible. Good sulfur resistance; phenolic resin has good covering performance and excellent corrosion resistance, but poor flexibility.

(3) Choose the appropriate film thickness. The thicker the coating film, the stronger the corrosion resistance of the coating film. Different canned products have different requirements for coating thickness, and the coating thickness must be selected according to the contents of the can during production. Only in this way can we not only meet the needs of food packaging, but also reduce production costs. The thickness of the coating film is different, and the corrosion resistance is also different, so it should be treated in detail during inspection.

a The oxide layer on the surface of the tinplate and the tin layer itself have certain acid resistance and the thicker the tin layer, the stronger the acid resistance, so pears, beans, pineapples, potatoes, celery, etc. can be directly packaged in high-tin cans without internal coating . However, in order to prevent the tin layer from being scratched during printing so that consumers can see a layer of food protection coating film when opening the can lid, a layer of 3-49/mZ coating film can be coated on the surface with low tin-plated iron. The cost is cheaper than high tinplate.

b有一部分食品需要罐内的一些锡溶解,形成游离锡离子,如果没有游离锡离子浅色食品的颜色往往会发暗.绿色蔬菜的色泽也会发生变化。在罐头内缺氧的状态下,锡离子与食品生成锡铬化物而除掉了食品中的硫化物此类食品的内涂膜一般要求在4一69/耐之间。在这一厚度范围内,涂层有一定的孔隙率,罐头内的物质通过这些孔隙渗透到锡层表面,将锡缓慢溶解形成锡离子.以利用锡离子的还原.改善食品的色泽从而达到延长保质期的目的。

c对于一般低酸性食品罐的内涂一次涂布厚度为6一89/m,即可满足包装需要。

(4)采用两次涂膜。对于强腐蚀性酸性食品一般采用内涂两次的办法,以提高内涂膜的耐酸蚀能力。第一次采用170一180℃的烘烤温度涂布干重为4一5g/mZ的涂膜,第二次再涂布总干重为6一g8/m,的涂膜,烘烤温度为205℃。

(5)防止内涂膜的划花。对于酸性食品罐的内涂一定要注意防止划花。在马口铁上涂布一层或多层特制涂料膜制成的容器称为涂料罐无涂布涂料的镀锡罐称素铁罐。对素铁罐而言r锡大大超过铁的面积.锡在大面积腐蚀后产生氢附着在露铁部位保护铁不被腐蚀。而对于涂料罐.涂膜层划伤只有局部的锡层暴露,锡对铁的保护作用减到最低限度由于集中于小范围的电偶形成深度腐蚀易造成穿孔。杨梅、樱桃、草苟等水果是易发生腐蚀穿孔的品种加工这种食品罐时应注意防止内涂膜划伤。

(6)涂料中添加铝粉或锌裔.含硫t比较高的八宝粥、肉类食品堆.在高温杀菌过程中游离的硫与锡易形成棕褐色的硫化锡及黑色的硫化铁,造成食品污染,这就要求内涂膜具有高耐硫性.否则易造成罐壁硫化而变色脱落,影响内容物的质t。一般生产时采用两次内涂的方法.第一次涂布加5%一7%的铝裔或锌裔的环氧酚醛树脂涂料,第二次涂布一层环氧酚醛树脂涂料,即可大大提高内涂膜的耐硫性。添加氧化锌的目的是除去动植物罐头受热分解产生游离的硫化物和氢硫化物离子,生成无色的硫化锌:避免在谁内擦伤部形成硫化铁黑色斑;添加铝膏的目的是改善涂膜的孔除率.提高涂膜的班盖性,防止动植物罐头受热分解产生游离的硫化物和氢硫化物离子透过涂膜腐蚀。另外酸性食品中不宜加入锌裔,个别绿色蔬菜也不宜加入锌有.

(7)控制好炉温.烘烤温度对内涂膜的聚合结膜非常重要.合适的烘烤温度能够保持树脂高分子的理化性能。温度低,结膜不充分.树脂高分子在马口铁表面的附普力差,分子间的孔除率大.耐腐蚀性差;温度太高,结膜易脆化.附粉力差,不易加工。生产中一般According to涂料供应商提供的技术资料选择好烘烤温度进行试验,并在此温度点上下10℃的范围调整,查看试片的耐腐蚀效果,从而找到生产车间环境下的很好的烘烤温度。实际生产时要注意炉内温度是否与温度仪显示的数值一致.

(8)制罐时采用补喷涂。马口铁印刷、上光、制罐过程中难免发生内涂膜表面擦伤.对于强腐蚀性的食品包装罐,一旦有伤痕就会在伤痕处发生强烈腐蚀.严重时造成雄穿孔.采用制雄后补喷涂的方法.能有效防止因划伤而造成食品雄耐腐蚀性下降的情况.特别像草每、杨梅、红樱桃、红色有萄汁等有色紊的水果.由干锡的还原作用使水果中的花色昔色素与锡结合成化合物同时产生酸,增强内容物的氧化能力,色素退色容器腐蚀严重,罐头氢胀。因此为了保险起见.强腐蚀性食品及有色素水果的包装在制罐时采用补涂是非常必要的。有制罐补涂的内涂膜只需一次涂布4一69/mZ即可.涂膜太厚,往往会造成涂膜的附着力差.不利于涂膜的防腐蚀性。

3.孔性电流

孔性电流主要是用来检测内涂膜孔隙率及加工过程中涂膜划伤的程度是否会影响内装物的品质。电流值越大,内涂膜的防腐蚀能力越差。特别是罐装物为酸性强的内容物时孔性电流愈大.耐酸性愈差。提高涂膜厚度、或两次涂膜及采用合适的烘烤温度,均能降低孔性电流。孔性电流是快速检测内涂膜耐腐蚀性的一种方法。

4.抗冲击性

对于月饼盒盖、三片罐底盖产品,机械加工时需成型冲击,在涂布这类产品时需要考虑表面涂膜的抗冲击性,影响马口铁抗冲击能力的主要因素有以下几点。

(1)涂膜厚度。涂布生产时.在烘烤温度一定的条件下,涂膜厚度太薄.不能遮盖好马口铁,使涂膜色泽呈现马口铁灰色色泽.特别是涂布白磁油.太薄根本不能使涂膜呈现白色,不利干印刷时各色套印后的色彩再现。此外,涂膜太薄时烘烤易过度硬化,冲击时易脆裂.涂膜厚度太厚.易造成马口铁表面涂料已烘干,命近锡层的涂料中有机溶剂未挥发掉不利于涂膜在马口铁表面聚合结膜,冲击成型时易出现剥离。因此对需冲击成型的产品需要在生产时控制好涂膜厚度。

(2)树脂的类型。不同树脂烘烤结膜后的抗冲击性不一样。对深加工的产品聚醋为更好。

(3)烘烤条件.烘烤温度偏低聚合结膜后树脂的化学键未充分文联固化冲击时易造成化学键断裂。温度太高印涂膜易脆化,机械冲击时易脱落。

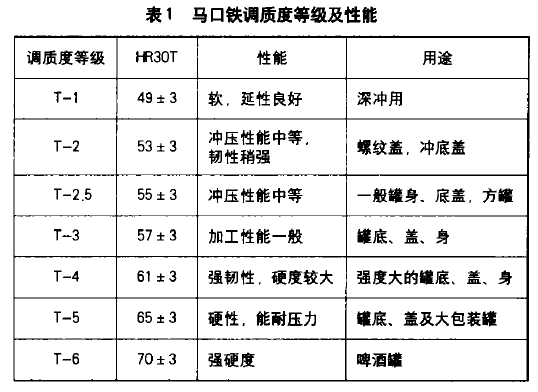

(4)马口铁的调质度。调质度主要在马口铁的退火工艺中形成.是表示马口铁机械性能的一个综合性指数.通常用洛氏硬度表示,下值越大其硬度也越高.抗冲击性能越差.因此生产时要注意对于抗冲击性要求高的产品要选用低调质度的马口铁.这一点往往被许多生产厂家所忽视.马口铁调质度等级及性能见表1

5.涂膜表面硬度

马口铁产品加工成型时要求加工过程中马口铁表面图案及涂膜不能脱落这就要求马口铁表面的涂膜有一定的硬度。影响马口铁涂膜硬度的主要因素是涂布光油、烘烤温度及涂膜附粉力。

(1)不同种类的光油上光后的硬度均有差异一般丙烯酸树脂的硬度比较高,环氧树脂最低.聚醋氮基树脂次之.光油中混有其他杂质涂料时也会降低外涂膜的硬度。

(2)烘烤温度偏低易造成涂料结膜树脂分子聚合链接不完全加工时易划花,温度偏高易造成涂膜脆化.硬度降低。

(3)涂膜的附着力差加工时涂膜易刮花,无疑造成涂膜的硬度偏低。因此上光及涂膜厚度不要太厚。

6.耐弯折

一般的马口铁印刷品在机械加工中有弯折卷边加工.因此印涂马口铁产品在生产中需要进行耐弯折检测,影响印涂膜弯折性的因紊主要有涂料的树脂类型、烘烤温度及涂膜硬度。烘烤温度太高易造成涂膜变脆,而温度太低又不利于树脂分子的聚合结膜,涂膜不耐弯折。对于僻拉伸弯折或缩紧弯折的产品,需要采用柔韧性好、附着性强的耐弯折的专用树脂涂料。一般来说,涂膜硬度越大.涂膜的柔韧性越差,弯折加工时易开裂因此对需深弯折加工的产品涂布上光膜的硬度不宜过高。

7.耐燕煮性

食品容器罐,在盛装食品后往往器经高温杀菌蒸煮.如果使用的内外涂料存在缺陷则易造成蒸煮后内涂膜起泡、变色、脱落.而外涂膜失光、渗色、退色、易划伤.这样一来容器罐失去了其包装价值。因此在对需蒸煮的食品罐进行涂膜时一定要注意以下几方面。

(1) According to the composition of the canned content, select a high-temperature cooking-resistant coating inner coating, and use an appropriate coating thickness, baking temperature and coating times to ensure that the powder adhesion of the inner coating film meets the process requirements. The film has the required corrosion resistance.

(2) The used white magnetic oil and varnish need to be matched, and have high temperature cooking resistance.

(3) When color matching is required when using high temperature resistant cooking ink, it is recommended to use the same resin series ink from the same manufacturer.

(4) It is better to use epoxy modified resin varnish for wet glazing. It can not only improve the retort resistance but also ensure that the glazing has good glazing performance. However, the high temperature of the modified epoxy resin Easy to yellow.

(5) Carry out cooking inspection before glazing, and take measures in time if problems are found. The general solutions include increasing the temperature, reducing the speed, changing to varnish, wet cover and dry glazing, etc.

- 1Why choose nbchao for experimental film instrument procurement?

- 2What are the requirements for preparing test samples for aqueous dip paint?

- 3Structure and Properties of Tinned Sheet Steel (Tinplate)

- 4Measuring levelling performance with black and white cardboard, Tinplate and levelling scraper

- 5Tinplate Appearance mass FAQ treatment

曾建辉 - 《广东健力宝富特容器有限公司》

- 6Causes and Countermeasures of FAQ in Tinplate Spreader

蔡史明 - 《东营胜德制罐有限公司》

- 7Development of PPESK High Temperature Self-Lubricating Wear-resistant Coatings

汤传贵;靳钊;蹇锡高 - 《涂料工业》

- 8Introduction of coating softness inspection method

- 9Coating powder performance testing - fusing flowability method