Viscosity measurement and applications

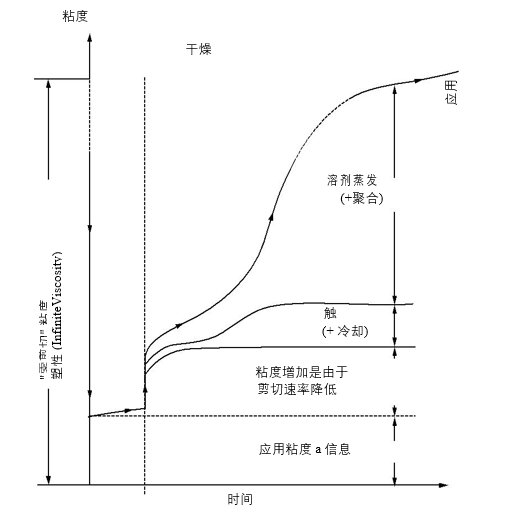

After a wet or liquid coating is applied to a substrate, its viscosity begins to increase. This increase is due to several factors, some of the more important ones as shown in Figure 2.8. The increase in viscosity due to different factors as shown in Figure 2.8 is typical for solution coatings. Low solids content. Of course, for highly concentrated solution coatings, the relative sizes will also vary. Solids level, as well as powder coating. In powder coatings, the main growth will be due to freezing, as the temperature approaches the melting point. Measuring the increase in viscosity is important because it gives us an idea of how much time.

It is suitable for the occurrence of various phenomena before solidification. The leveling and sagging phenomena discussed above are only possible if the material is kept flowing; as the viscosity increases, these become less and less important to the process as the rate and level of sagging decreases. Velocity according to equations 2.7 and 2.11. In fact, using the measured time-dependent viscosity, it is possible to estimate the time t (clotting time) used in Equation 2.8, as well as the advection time, in Equation 2.11. Generally, if the viscosity is above about 100,000 P, then leveling and sagging occur to a negligible extent.

Experimentally, the increase in viscosity can be monitored using an oscillatory technique (see section). 2.2.2). This method is preferred because measurements can be performed under low shear conditions. Amplitude, close to the condition after coating application. Furthermore, the freezing point can be estimated from the measurement of the elastic modulus. After coating under simulated conditions, vibration measurements should be performed at a very high speed with shear—corresponding to the method of application. 36 In such experiments, the average amplitude of the torque/stress wave increases with time after cessation of ramp shear. Although it is not easy to calculate. Variations in the magnitude of the viscosity change are estimated to be possible. 37 Optionally, the amplitude of the associated stress can be used. Correlation between viscosities found in Dodge 36.

The level after application and the degree of quantification of the level through special techniques. Another way to use the 38 is to roll the sphere onto a coating on a sloped surface. The velocity of this sphere serves as an indicator of viscosity, properly calibrated in Newton.

For non-Newtonian fluids, this approach may be misleading, since the flow is not viscous, it is not applicable. A more acceptable technique is to use simple shear, with one plate. Movement at a constant speed on a horizontal coating.

- 1How to Choose a Conical Rotor for Viscosity Measurement

- 2Rotary ink viscosity measurement

- 3The importance of viscosity measurement in food production and processing

- 4How to measure Coating Viscosity?

- 5Viscometer measurement of different types of Viscosity

- 6How to save time and money with proper measurement Viscosity?

- 7Viscosity cup measurement why specify the temperature?

- 8Viscosity and Viscosity measurement

- 9Viscosity cup usage limitations