9 important performances of Armoloy Chromium

thickness

Armoloy is applied on a very thin layer of metal, on top of this. Coatings range from 0.000040 to 0.0006. Each side (1 to 15 μm). The average deposit per side for normal proofs is between 0.0001 and 0.0002. (2.5~5μm) range. Tolerances can be kept within 0.000050. (1μm) deposits up to 0.0002. Each side (5 μm). Control ±Armoloy 0.000025 if desired. per side (0.5 μm). There was no change in the conductivity or magnetism of the base metal.

Armoloy thickness is always in direct relation to the base metal, it will vary from one base metal to another. However, the thickness established for each will remain constant and predictable. At the end of all applications that call for monitoring deposit thickness checks, the Armoloy recommends the use of an anti-corrosion agent to determine deposit thickness. This method is non-destructive to the base metal.

Adhesion

Armoloy will not chip, peel, crack, flake, or separate base materials in the ASTM standard bend test or under conditions of extreme heat or cold (from 440 to 1600–°F). Armoloy coatings form a durable bonding surface through the surface porosity of the base metal. The removal of metals can be done on a basis of no adverse effects by authorizing the Armoloy Armoloy plant.

Corrosive

Armoloy is resistant to attack by most organic and inorganic compounds (except sulfuric and hydrochloric acids). The Armoloy coating is usually more noble than the substrate; therefore, it protects against corrosion without porosity, cracks, and discontinuities, and provides a uniform structure and chemical composition. The porosity, hardness, and surface finish of the base metal will affect the corrosion resistance of Armoloy; however, it is coated with all base metals of Armoloy to enhance the corrosion resistance properties. Samples were subjected to the standard ASTM B-287 salt spray test. Armoloy also meets MIL QQC 320B, AMS 2406 and AMS 2438 standards.

wear resistance

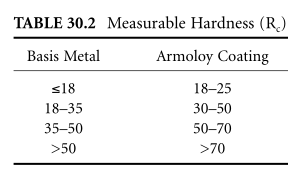

Armoloy is a hard chrome surface, measuring 70 to 72 RC, applied. "Application" refers to the Armoloy coating hardness measurement when it is applied to the metal on the basis of the measurement. The base metal plays an important role in determining how wear resistant the Armoloy surface will be. Generally, the measured hardness increases by 10 Armoloy to 15 points, as shown in Table 1.

Armoloy is always 70 to 72 RC. However, the base metal directly affects the measurable hardness. The harder the base metal, the harder Armoloy can measure . Surface hardness should be measured by the Knoop or Vickers method with a load of 5 to 10 grams at a diamond point.

A high hardness value indicates good wear resistance, but there are other factors to consider. Corrosion and lubrication also affect wear. Improving Wear Resistance Armoloy is not only very hard but also corrosion resistant, improving lubricity by interacting with the microspheres on the ball surface.

Lubricity

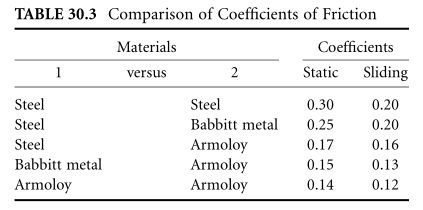

Used to apply a special technique for rendering Armoloy self-lubricating, creating a spherical surface. Armoloy's low coefficient of friction is invaluable in extreme temperature conditions. Table 2 gives the coefficient of friction on various materials at 72°F without lubricant.

An additional feature is its ability to operate on its own in Armoloy coatings for tribologically related applications. The surface of the special module (orange peel) is created by the Armoloy process allowing a special "Armoloy to Armoloy" function to reduce frictional properties. The modular surface creates good lubricant retention and continuous dispersion, which helps provide other low-friction properties. Pay particular attention to the tolerances of the equipment that the Armoloy will be operating with another Armoloy surface.

consistency

Armoloy conforms perfectly to the surface of the base metal. All threads, flutes, and even scratches are reproduced in detail. Armoloy works better when applied to smoother surfaces (12–32 RMS). The RMS completion will improve slightly, down to about 8 rms. Below 4 rms, this process may slightly prevent the finishing of the part.

Inner and outer surfaces of nearly all shapes and configurations can be machined uniformly. Grooves or grooves smaller than 0.187 inches. Wide, deeper than wide, and less than 0.187 inches in diameter. In diameter special engineering will be required to ensure a uniform coating.

Thermal resistance

Armoloy will withstand temperatures above 1600°F and temperatures from 440 to 1800–1800°F. Armoloy will react in the gas phase with carbon monoxide, sulfur, and phosphorus and begin to soften. In bright red heat, oxidation occurs in an atmosphere of steam or alkaline hydroxide. Hardness, wear resistance, and corrosion resistance will all decrease above 1600°F. Conversely, temperatures below 200°F. Armoloy coatings will remain largely stable.

brightness

Armoloy is used as a final coating on parts and equipment. It has a very nice smooth silver matte with a "micro orange peel" finish. If necessary, its Armoloy polished surface finish and reflectivity can be enhanced after coating .

hydrogen embrittlement

In all electrochemical plating processes, free hydrogen ions are released. Typically, these ions are trapped in the molecular structure of the base material, leading to hydrogen embrittlement. The following conditions make hydrogen embrittlement very unlikely with the Armoloy process:

• No acid is used in the preparation process.

•Steam explosion (liquid honing) or dry honing procedures help to remove residual surface stresses.

• No 'back-clean' or etchant is used on parts treated with Armoloy.

Plating cycles are short, and Armoloy chromium deposits rapidly. Armoloy seals the surface porosity of the base metal in a hydrogen ion-invasive base metal surface. However, the postplate Armoloy can be heat treated to specification if desired.

- 1Working principle and application of UV coating Cupping testing device

- 2Application of shakeout Tester in organic polymer film abrasion resistance testing

- 3Application of shakeout Tester in aluminum surface coating abrasion resistance testing

- 4Paint film abrasion resistance and test method thereof

- 5Polyethylene (PE) coating indentation hardness inspection and its importance in pipeline corrosion protection

- 6Paint film abrasion resistance and its test method - rubber abrasive wheels method

- 7Determination of abrasion resistance of paint film

- 8Determination method of paint film abrasion resistance and its importance

- 9Coating performance testing: the key to ensuring quality coatings