Determination of Coating Fineness

Instruments and reagents

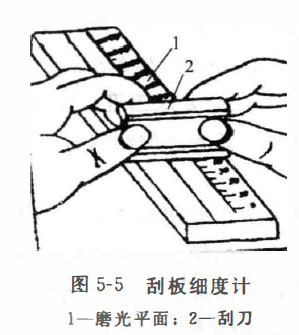

Scraper Fineness Meter; scraper; paint pot; paint mixing knife; soft rags; thinner; anti-rust oil; paint sample, etc. The scraper Fineness Meter and scraper are shown in Figure 5-4.

Method and principle

Fineness refers to the readings obtained on the standard fineness plate under the specified test conditions, which characterizes the size or degree of dispersion of pigments, fillers and other particles in the paint. The measured value is not the size of a single pigment or extender pigment particle , but the size of the agglomerates that exist after the pigments are ground and dispersed during the production process of the color paint. Paint fineness is one of the routine inspection items for paint production.

The fineness of the paint affects the durability of the paint film. The pigment particles protrude from the paint film and are easily eroded by the outside sun and wind or mechanical force. These protruding particles will come out of the paint film, leaving fine particles on the surface of the paint film. Pinholes gradually become corrosion-prone centers due to water permeability, which affects the durability of the paint film and reduces its protective performance on the substrate.

In addition, the fineness of the paint also affects the storage stability of the paint. The paint with fine particles and good dispersion is not easy to precipitate and agglomerate; it affects the adhesion. The finer the grinding fineness, the adhesion of the paint film may be reduced.

The current standards implemented include GB/T6753.1-2007 "Determination of Grinding Fineness of Paints, Varnishes and Printing Inks" (equivalent to the international standard ISO1524:2000), GB/T1724-79 (89) "Determination of Coating Fineness ". Generally speaking, when the fineness is below 30 μm and 30 μm, a scraper Fineness Meter with a range of 50 μm is used, when the fineness is 31-70 μm, a scraper Fineness Meter with a range of 100 μm is used, and when the fineness is above 70 μm, a scraper Fineness Meter with a range of 150 μm is used. count. The graduations and recommended ranges of typical fineness plates are shown in Table 5-2.

Measurement steps

1. GB/T 1724 Coating Fineness Determination Procedures

Before use, it is necessary to carefully clean the scraper Fineness Meter (Figure 5-5) and the scraper with a soft regular cloth and a solvent. Stir the sample thoroughly with a small paint knife, drop a few drops of the sample into the deepest part of the groove, and fill the groove with a little excess. Hold the scraper with both hands, and place the edge of the scraper horizontally on the upper end of the deepest groove of the Fineness Meter (at the edge of the sample), so that the scraper is in vertical contact with the surface of the polished flat plate. Within 3s, use a scraper to scrape the sample vertically across the entire length of the groove, so that the paint sample fills the groove without leaving any residual paint on the plate. Immediately (not exceeding 5s) after the scraper is pulled, observe the line of sight and the groove plane at an angle of 0-30° for 1s, find out the scale value of the judgment point, which is the fineness of the sample, and record the reading (accurate to the minimum scale value) ).

对光观察沟槽中颗粒均匀显露处,以μ.m表示。如有个别颗粒显露千其他分度线时, 则读数与相邻分度线范围内, 不得超过三个颗粒。如图5-6 所示为GB/T 1724 读数示意。

平行试验三次, 试验结果取两次相近读数的算数平均值, 而两次读数的误差不应大于仪器的最小分度值。

注意事项

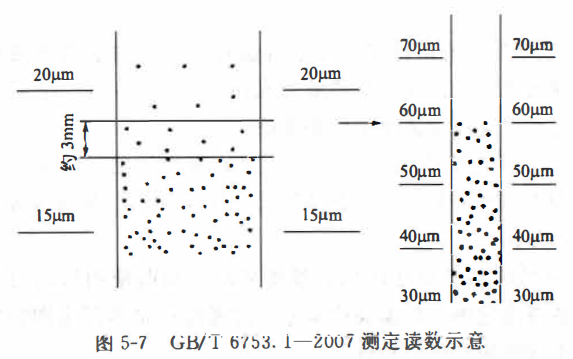

1按GB/T 6753. 1-2007规定的方法测定读数时, 与细度板表面的角度为不大于30 ° , 不小于20°。

2测定前需要正确选择量程。

3测定后需要用防锈油将细度计和刮刀保护起来。

4被测产品的取样需要具有代表性。如对于三辐机, 应分在漆液中间和两边采样;对于成品, 应在包装前实施多次细度监测。

5被测漆液的黏度将会影响细度测定。通常涂料的黏度与细度成反比, 因此对于成品的细度检验应在符合其黏度标准的试验条件下进行。

6溶剂的挥发速度会影响涂料的细度测定。溶剂的快速挥发,将导致被测漆液的细度变化, 所以测定其细度时, 需要在规定的时间内读出细度值。

7被测漆液中存在气泡也会影响细度测定。因此涂料经搅拌后应稍加放置使气泡逸出, 取样滴入细度板沟槽时, 更要注意避免气泡。

8冬季生产的水性漆, 由于气温过低, 有时会使漆液中乙醇胺和水凝析出来, 因此应将漆液用水加热至40-50 °C, 再冷却到室温后测定细度, 进而保证测定结果准确。

9每次测定完毕后应立即用适宜的溶剂仔细清洗细度计和刮刀, 长期不用时要用中性矿物油将其涂抹保护, 以免细度板表面受蚀而影响使用。

10通常因刮刀硬度比细度板硬度低, 长期使用后刮刀刃易受磨损, 造成测定细度值偏高的误差, 故需由计量部门定期检定, 使用过程中则要随时注意检查。当以刮刀刀刃与细度板面垂直接触时, 要经常观察刮刀与细度板沟槽的最浅位置之间是否透光, 一旦发现透光即表明刮刀刀刃磨损严重, 则此刮刀不能继续使用, 否则将会损伤细度板的沟槽。

11 On July 1, 1996, the State Bureau of Technical Supervision promulgated and implemented the National Measuring Regulations CJJG905-1996 for Scraper Fineness Gauge, which became the standard for measurement departments all over the country to regularly test new manufacturing, in-use and after repairs. The measurement range is 0 -Technical specifications for verification of 15μm, 0-25μm, 0-50μm, 0-l00μm and 0-150μm scraper fineness gauges.

- 1Coating fineness of ground - Fineness gauge

- 2Coating fineness test method and influencing factors

- 3Introduction to the function, production process and use method of latex paint Fineness gauge

- 4Fineness Detection of Precious Metal Slurry in Microelectronic Technology with Fineness Meter

- 5Inks Fineness gauge principle results and usage introduction

- 6Basic Principle and Application Analysis of Coating Fineness Scraper

- 7Fineness gauge selection guide notes

- 8Coating Fineness Determination and Its Importance

- 9Detection Steps of Coating Fineness and Operation Method of Ground Gauge